Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

AFV

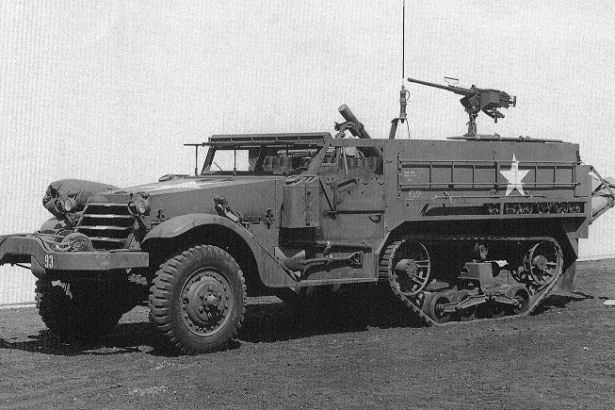

Self-Propelled Mortar Carriers I

M21 81mm Mortar Carrier at tests Half-track carriers were one of the most versatile designs of all armoured fighting vehicles to be used during the Second World War. The Japanese Army had this type of vehicle, as did the French Army, but it was the German and American armies which developed their half-track vehicles to serve in a whole range…

Most Recent

76-mm Sherman

Standard M4A2(76mm) Sherman M4A3(76mm) Sherman The US Army made a conscious decision in 1943: to ignore calls for rapid development of the heavy, 90mm-gun T26 (Pershing) to take on the Panthers and Tigers, and instead to mass produce the M4 – a medium tank that would do the job well…

Infantry Fighting Vehicle Puma

The Puma is an Infantry Fighting vehicle developed in Germany to replace the aging fleet of German Marder IFVs. The vehicle is considered to be one of the most well protected and heavily armored IFVs in the world. The Puma also offers substantial firepower, mounting a 30 mm autocannon in…

US Army Bradley in Service

An M2A3 of 2-162 Infantry drives out of Patrol Base Volunteer in Sadr City during a QRF (Quick Response Force) mission. Note the prominent CIV, so vital to the Bradley’s effectiveness in urban operations in Sadr City and elsewhere in Iraq. The familiar twin pillars of US armoured might in…

“Sturmtiger” at Warsaw Uprising

A little known episode from the fighting during the Warsaw Uprising in August and September 1944, involved the operations carried out by 1000. Sturmtiger-Kompanie. A prototype of the Sturmtiger was sent to Warsaw and off-loaded at the station in Pruszków on August 15, 1944. This station was prepared for receiving…

Matilda at Arras

By the outbreak of war with Germany in September 1939 there were only two Matildas in service, though 16 had been issued to 7th Royal Tank Regiment in France by early 1940 where they were used with success in the Battle of Arras just prior to the Dunkirk evacuation. The…

Automitrailleuse Panhard et Levassor Type 178

A Panhard 178B. The APX3B turret is of the latest type with a rear episcope. Rear view showing the position of the second driver; the hull, despite having been repainted with a number belonging to the third production batch. Panhard 178B/FL1, French Indo-China, 1947. Panhard 178 tank hunter with the…

Most Popular

76mm Gun Motor Carriage T86, T86E1, and T87 (Amphibious)

T86 GMC (Amphibious) showing new flotation hull on M18 chassis. T87 GMC (Amphibious) with 105mm…

Tigers – The Heavy Punch II

German commanders kept them back as a reserve to counterattack against Soviet breakthroughs, and only…

General Motors XM-1

General Motors XM1 prototype Congress canceled the MBT-70 in November and XM803 December 1971, and…

The Survivability of Tanks and Crews

This latest Soviet heavy tank was adopted and then deployed during the Winter War with…