Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Soviet

Martyrdom on the Volga

In war, it is often glibly said that ‘fortune favours the bold’; whether the bold actually deserve or receive such benefit is seldom questioned. By late December 1942, any last luck had run out for the German Sixth Army in Stalingrad, as it had done so for the Soviet defenders of Sevastopol six months earlier. Common to these two sieges…

Most Recent

‘Istrebitel Sputnikov’ (IS)

An artist’s conception of a Soviet anti-satellite weapon destroying a satellite in 1984. The Russian satellite destroyer known as ‘Istrebitel Sputnikov‘ (IS). Carrying an explosive charge, it would be guided on an intercept course towards enemy satellites. America’s ability to gather intelligence on Soviet developments was severely limited during the…

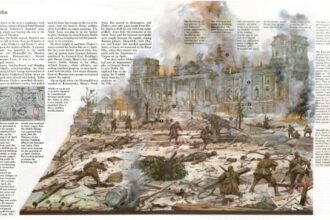

Final Assault on the Reichstag

A total of 89 heavy artillery guns and Katyusha rocket launchers were trained on the Reichstag for a thunderous barrage before the infantry stormed it, turning the structure into a ruin. When the Reichstag was finally taken on 30 April 1945, Soviet soldiers swarmed through its elegant hallways to scrawl…

Col. David Glantz – Red Army before Warsaw 1944

SS-Obersturmführer Karl Nicolussi-Leck (Panther’s cupola), commander of 8./SS-Panzerregiment 5 of the Wiking Division, and a Sd.Kfz. 251/3 Ausf. D, during the battles east of Warsaw, August 1944. Between August 18-22, IV.SS-Panzer-Korps, comprising the Totenkopf and the Wiking Division, destroyed 98 Soviet tanks destroyed in the battles around Warsaw. Soviet (1st…

The Mainstay

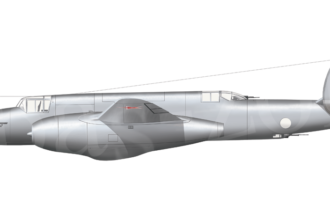

The Beriev A-50 is perhaps the most important system in the Russian military’s airborne inventory, reflected in the type’s intense workload and the importance attached to its upgrading. In early 2011, the Russian Air Force’s (Voyenno- Vozdushniye Sily – VVS) airborne early warning and control (AEW&C) force entered a new…

Kolberg in 1945

Kołobrzeg (Kolberg) in 1945. 80% of the city was destroyed during the war. In November 1944 Kolberg, a large Baltic seaport in the Prussian Province of Pomerania, was designated a stronghold as Festung Kolberg. It was one of the key German positions in the Pomeranian Wall, a vital link between…

Germany Army in the East, Late 1942-Mid 1943 Part I

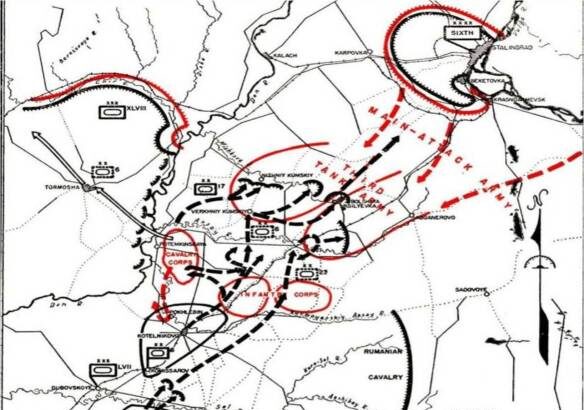

The repulse in December of Hoth’s attempt to break through to Stalingrad enabled the Soviet command to reactivate one of the original elements of ‘Saturn’, the attempt to cut off the retreat of Army Group A from the Caucasus. The General Staff recommended that the Southern (formerly Stalingrad) Front, while…

Most Popular

Lend-Lease to the USSR

American Lend-Lease supplies to the USSR 1941–45. Soviet historiography is mocked in the West, where…

Soviet Navy WWII Aircraft Carrier Design

PROJECT KOSTROMITINOV Aircraft 66 Fighters 40 bombers/torpedo bombers Guns 8×2 152 mm 4×3+6×2 100mm FlaK…

The Grain Elevator – Stalingrad

As Gruppe Edelsheim reaches the southern railway station around 1600 hours they pass close to…

Mikoyan MIG-23

MiG-23 MF/BN FLOGGER The Soviet-designed fighters were agile. In an engagement, the enemy’s first turn…