Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

British

Mercenary from the Three Kingdoms of the Commonwealth

Patrick Gordon As opportunities for military employment dried up in the Three Kingdoms, the Netherlands and Scandinavia in the 1650s and 1660s, soldiers of fortune from the British Isles were driven to look further afield. As Muscovy opened a window on the west and sought to modernize, Scottish and other foreign officers were useful in importing and introducing western European…

Most Recent

Elizabeth towards War I

European matchlock musketeers of the Elizabethan period. By the early 1570s the Puritans had grown significantly in numbers and in economic and political clout. They were not only unsatisfied, however, but increasingly discontented. At the same time that they were trying and failing to pressure the government into killing Mary…

Elizabeth towards War II

What is often depicted as the apotheosis of the Elizabethan Age, the turning point at which the wisdom of everything the queen had done was made manifest and the way was cleared for England’s emergence as the greatest of world powers, came in the third week of July 1588. It…

Dargai, 20 October 1897 Part I

The Gordon Highlanders storming Dargai Heights during the Tirah campaign in 1897. It was here that Piper Findlater won his VC. He was wounded and unable to walk and exposed to enemy fire. Despite this and his exposed position he continued playing, to encourage the Highlanders in their assault on…

Dargai, 20 October 1897 Part II

Storming the Dargai Heights. Darkness put an end to the fighting. In addition to the casualties mentioned above, the Gordons had sustained another man killed and seven wounded. Dead and wounded alike were carried down the rough two-mile track to the road, on reaching which the battalion formed up and…

The Assault on Levita

The survivors of the enemy convoy sunk on 7 October 1943 were landed on Stampalia, where the LRDG had M2 patrol. A small naval craft (the Hedgehog) dispatched from Leros to bring back ten prisoners of war for interrogation, called with engine trouble at Levita, about twenty miles to the…

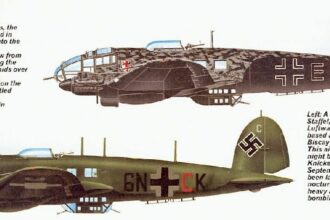

Operation Airthief – the plan to hijack an Fw 190A

Armin Faber’s Focke-Wulf Fw 190A-3 of III/JG 2 at RAF Pembrey, June 1942. In June 1942, Oberstleutnant Armin Faber was Gruppen-Adjutant to the commander of the III fighter Gruppe of Jagdgeschwader 2 (JG 2) based in Morlaix in Brittany. On 23 June, he was given special permission to fly a…

Most Popular

AMPHIBIOUS ASSAULT IN BRITTANY, 1758

British coastal assault on St Cast in Brittany in September 1758. A German map, published…

The Hanoverian Army at Waterloo

The Hanoverian contingent in Wellington’s army was integrated fully into the British divisional structure; it…

Elizabeth towards War I

European matchlock musketeers of the Elizabethan period. By the early 1570s the Puritans had grown…

Dargai, 20 October 1897 Part I

The Gordon Highlanders storming Dargai Heights during the Tirah campaign in 1897. It was here…