Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Germany

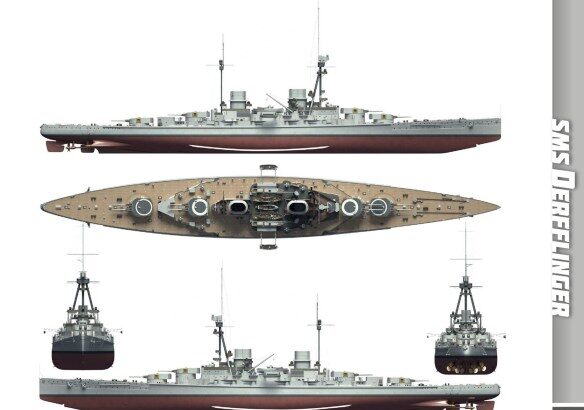

SMS Derfflinger III

Derfflinger was struck only once during the battle. At 11.40 a 13.5in shell struck the belt armour 1.15m above the waterline to starboard at frame 181 and detonated without penetrating. Here the belt was 300mm thick. The plate was pushed in approximately 10cm and was left with an indentation 30mm deep and concentric rings for about 2m around the point…

Most Recent

Focke Wulf Fw 190D-9 Dora

Arguably, the Focke-Wulf Fw 190 evolved into wartime Germany’s most effective fighter, offering the Luftwaffe the benefit of manoeuvrability combined with stability as a formidable gun platform and the flexibility to perform as an air superiority fighter, a heavily armed and armoured interceptor and as an ordnance-carrying ground attack aircraft.…

HERBSTNEBEL – Special Forces

Above is one of the rare pictures of this operation. Von Der Heydte is on the right, his arm injury clearly visible. In the center is Von Kayser and to the left is one of the jäger involved in the operation. The stress of the operation clearly shows on Von…

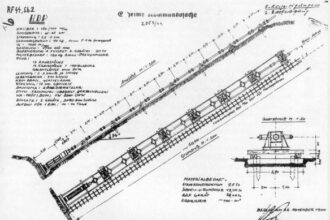

German Schnellboot (S-boat)

Schnellboot S-80 torpedo boat Camo Operations with the Kriegsmarine S-boats were often used to patrol the Baltic Sea and the English Channel in order to intercept shipping heading for the English ports in the south and east. As such, they were up against Royal Navy and Commonwealth (particularly Royal Canadian…

Operation Airthief – the plan to hijack an Fw 190A

Armin Faber’s Focke-Wulf Fw 190A-3 of III/JG 2 at RAF Pembrey, June 1942. In June 1942, Oberstleutnant Armin Faber was Gruppen-Adjutant to the commander of the III fighter Gruppe of Jagdgeschwader 2 (JG 2) based in Morlaix in Brittany. On 23 June, he was given special permission to fly a…

Fw 190 – Entry into service In March 1941

Oberleutnant Otto Behrens assumed command of Erprobungsstaffel 190 based at Rechlin- Roggenthin. The unit received six pre-production Fw 190A-Os and its brief was to test the new tighter under service conditions. The pilots and ground crews assigned to the Erprobungstaffel were drawn from II. Gruppe of Jagdgeschwader 26, and the…

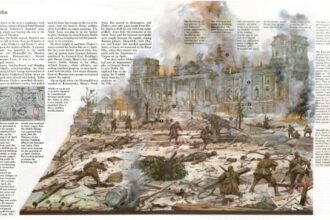

Final Assault on the Reichstag

A total of 89 heavy artillery guns and Katyusha rocket launchers were trained on the Reichstag for a thunderous barrage before the infantry stormed it, turning the structure into a ruin. When the Reichstag was finally taken on 30 April 1945, Soviet soldiers swarmed through its elegant hallways to scrawl…

Most Popular

German Schnellboot (S-boat)

Schnellboot S-80 torpedo boat Camo Operations with the Kriegsmarine S-boats were often used to patrol…

Focke Wulf Fw 190D-9 Dora

Arguably, the Focke-Wulf Fw 190 evolved into wartime Germany’s most effective fighter, offering the Luftwaffe…

German Transport System WWII

German BR 52 locomotive, 1944 by Frédéric Mouchel A BR 52 locomotive at work during…

Flak towers: then and now

The construction of Flaktürme (Flak towers) in major cities began in response to the first…