Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Warship

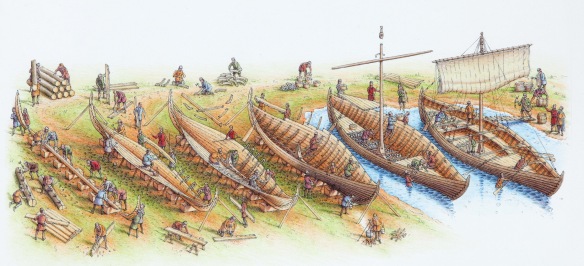

‘steeds of the waves’

Building a Viking-Ship The earliest Viking vessels were copied from Roman or Celtic designs and powered by oars instead of the usual paddles. Like all ships of the time they were slow and prone to capsizing in rough seas, appropriate for short trips that hugged the shore. Sometime in the eighth century, however, the Vikings invented the keel. This simple…

Most Recent

German Schnellboot (S-boat)

Schnellboot S-80 torpedo boat Camo Operations with the Kriegsmarine S-boats were often used to patrol the Baltic Sea and the English Channel in order to intercept shipping heading for the English ports in the south and east. As such, they were up against Royal Navy and Commonwealth (particularly Royal Canadian…

Borodino class

In 1904 Moscow dispatched the 2nd Pacific Squadron, commanded by Admiral Zinovi Petrovich Rohdzsvenski, from the Baltic to the Pacific, halfway around the world, to salvage the desperate situation in the Pacific. Rohdzsvenski’s main units numbered eight battleships, three armored cruisers, and three hopelessly obsolete armored coast-defense warships. The core…

Deutschland class

As long as Chancellor Otto von Bismarck remained in power, the German Navy was distinctly subordinate to the German army in the counsels of government, and the navy was relegated basically to a coast-defense mission. (Until 1888, the year of Kaiser Wilhelm II’s accession, the navy had actually been run…

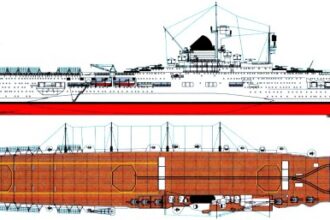

Graf Zeppelin I

Plans for a shipped-based air force started soon after Hitler became Chancellor in 1933. The first plans were limited to supplying the existing battleships and cruisers with reconnaissance seaplanes. On March 12th 1934 the first requirements the future aircraft carrier was given. Within a year the design study had been…

Graf Zeppelin II

Last photograph of Graf Zeppelin towed from Swinocijscie Poland to Leningrad. April 17. 1947. In April 1945, Soviet troops found the carrier’s artillery had been dismantled, the installation of fire control equipment had not been finished and the electrical installations partially installed as well as the flight equipment. There was…

The Battleship Race Won and the Strategy Lost

USS Arizona Built in 1913 and was the second and last of the Pennsylvania Class “super-dreadnought” battleships and primarily served stateside during WWI. She was part of the escort of the USS George Washington that carried President Wilson to the Paris Peace Conference on December 13, 1918. 31,400 tons and…

Most Popular

German Schnellboot (S-boat)

Schnellboot S-80 torpedo boat Camo Operations with the Kriegsmarine S-boats were often used to patrol…

Soviet Navy WWII Aircraft Carrier Design

PROJECT KOSTROMITINOV Aircraft 66 Fighters 40 bombers/torpedo bombers Guns 8×2 152 mm 4×3+6×2 100mm FlaK…

Borodino class

In 1904 Moscow dispatched the 2nd Pacific Squadron, commanded by Admiral Zinovi Petrovich Rohdzsvenski, from…