Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Small Arms

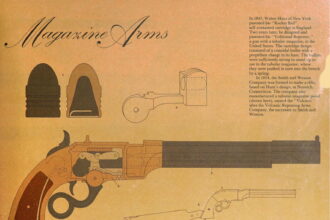

THE MAGAZINE RIFLE II

General Crozier, as he had instantly become, had a very senior backer. This was President Teddy Roosevelt, who had succeeded President William McKinley after the latter’s assassination in September 1901. So on 7 April 1902 Crozier authorized the first production of the new Springfield 1901 rifles. By 16 February 1903 the work was finished and the rifles were ready for…

Most Recent

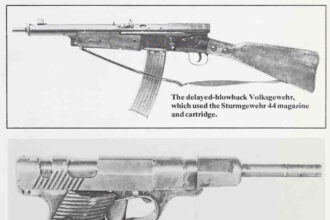

Volkssturm Small Arms

Primitiv-Waffen-Programm As a last-ditch measure in the nearly lost war, on 18 October 1944 the Deutscher Volkssturm was mobilized – a German national militia. To arm them under conditions of depleted manpower and limited available production capacities the Primitiv-Waffen-Programm (“primitive weapons program”) was initiated. It called for weapons that were…

Königgrätz: Battle of Eagles

The Prussian military system had been thoroughly reformed after Napoleon had crushed it at Jena in 1806. The crucial development was the growth of a Great General Staff, embodied in law in 1814. Bright officers were selected to what was effectively a military brotherhood, charged with continuous study of the…

Antimaterial Rifle

South African DENEL 20X110HS NTW-20 Rifle procured for evaluation in the United States The antimaterial (antimateriél or equipment) rifle is the successor to the antitank rifle of World War I and early World War II. Essentially a large-caliber, high-velocity rifle firing special armor-piercing ammunition, it is designed to operate against…

The Great British Machine Gun Controversy

The Vickers was used for indirect fire against enemy positions at ranges up to 4,500 yards (4,115 m) with Mark VIIIz ammunition. This plunging fire was used to great effect against road junctions, trench systems, forming up points, and other locations that might be observed by a forward observer, or…

The MP18 mystery

One weapon of close combat that has been associated with German assault troops is the MP18 submachine-gun. The German Army had been swift to perceive the potential for highly portable, short-range, automatic weapons and had begun experimenting with various concepts from 1915 onwards. In 1916 they had tested a fully…

THE MAGAZINE RIFLE I

Bolt-action rifles were standard during the whole period of World War I, and some served until after World War II, particularly the Lee-Enfield; the Springfield 1903, which was first issued as an infantry rifle and then later as a sniper rifle; the Mauser, although shortened from the Gew 98 to…

Most Popular

WWI Austro-Hungarian Small Arms Part I

Roth-Steyr Models 1907 and 1912 Austria-Hungary finally moved to replace its aging Rast-Gasser revolvers with…

Antimaterial Rifle

South African DENEL 20X110HS NTW-20 Rifle procured for evaluation in the United States The antimaterial…

Soviet WWII Machine Guns

The Soviets were latecomers to machine-gun development generally. Prior to World War I, the czarist…

Volkssturm Small Arms

Primitiv-Waffen-Programm As a last-ditch measure in the nearly lost war, on 18 October 1944 the…