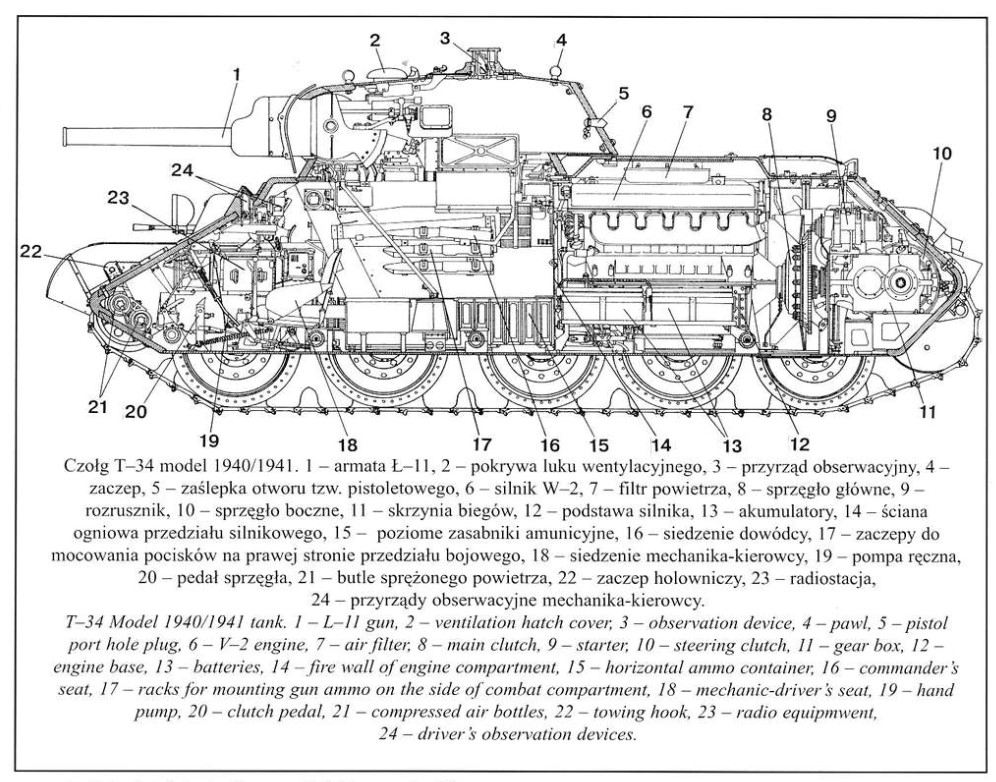

ARMAMENT

The early T-34 Model 1940 was armed with the short 76.2mm (3in)

L-11 Model 1938 rifled gun with a length of 30.5 calibres. During 1941 a very

small number of T-34s were fitted with the 57mm (2.24in) ZiS-4 long-barrelled

high-velocity weapon, which was intended for engaging lightly armed vehicles at

longer ranges. The high velocity of this weapon compensated for the loss of

calibre, and the L-11 remained the standard gun on the Model 1940 production

run, although it was not exactly up to the standard that the Soviets were

seeking for a gun, and the T-34 designers were not totally satisfied with the

weapon.

Fortunately there was a better gun available, although

Soviet bureaucracy and the interference of Kulik, the head of the GAO, did much

to hamper its introduction. Grabin and his team at Zavod Nr 92 already had a new

76.2mm (3in) gun in production. The F-32 was being fitted to the new KV heavy

tank and was achieving much better antiarmour performance than the T-34 Model

1940s L-11, due to its longer barrel.

By the end of 1940 a member of Grabin’s team, P. Muraviev, had

adapted Grabin’s F-32 gun for the T-34 and produced a weapon (the longer F-34

with 42 calibres) considerably superior to the L-11. In a move showing

considerable initiative and courage, Grabin and the director of Zavod Nr 92, A.

Elyan, began producing the F-34 alongside the L-11 and shipped them to the

Kharkov plant which was building the T-34. The initial F-34 guns were completed

in January 1941 and the first T-34s, usually classified as the T-34 Model 1941,

armed with the F-34, rolled out in February 1941.

They were mainly used as platoon and company commander

tanks, and proved very popular in combat after the German invasion, due to

their increased hitting power. Stalin became aware of the new version through

front-line correspondence. So as units involved in the fighting demanded more

tanks equipped with the F-34, rather than the less effective L-11, the Main

Defence Committee finally authorized the F-34 in the summer of 1941.The 76.2mm

(3in) F-34 Model 1940 (42-calibre length) gun equipped all subsequent models of

T-34 until increases in German armour protection led to the adoption of an 85mm

(3.34in) gun in late 1943, though tanks armed with the F-34 remained in service

until the end of the war.

IMPROVEMENTS

In the beginning, T-34s were produced at the Stalingrad Tractor

Factory and, immediately after the German invasion started, production began at

the Krasnoye Sormovo Factory in Gorky where major problems soon plagued the

assembly process. Defective armour plating was discovered and a shortage of the

new V-2 diesel engine was slowing the assembly line there. A critical shortage

of the costly radios for the T-34 required that the sets be allocated to the

tanks built for the company commanders only, thus all other tank commanders

were required to signal to one another using flags. Problems with the main gun

led to a new 76mm gun originating from the Grabin design bureau at Gorky, but

no official production order was actually issued until after Russian troops

used the weapon on the battlefield and praised it, after which the Stalin State

Defense Committee gave official permission for its manufacture.

With the German invasion in June 1941, the Soviets froze

further development of the T-34 and dedicated its assembly lines to full

production of the tank at its current stage of evolution. As the German armies

rapidly advanced into Soviet territory, their presence forced the evacuation of

the major Russian tank factories to relocation sites in the Ural Mountains, a

huge undertaking that had to be achieved in great haste. Main manufacturing

facilites were quickly set up at Dzherzhinski Ural Railcar Factory in Nizhny

Tagil, which was renamed the Stalin Ural Tank Factory. The Kirovsky Tank

Factory and the Kharkov Diesel Factory were relocated to Chelyabinsk which was

soon nicknamed ‘Tankograd’ and the Voroshilov Tank Factory of Leningrad was

incorporated into a new Ural factory at Omsk. A number of small ancillary

supply factories were absorbed into the Ordzhonikidze Ural Heavy Machine Tool

Works in Sverdlovsk. By the end of this whirlwind set of relocations, some

forty percent of all the T-34 production was occurring at the Stalingrad

Tractor Factory, and during the heavy fighting in the Battle of Stalingrad of

1942, material and spares shortages developed causing critical manufacturing

problems and resulting in some quality-control difficulties and in some tanks

being rolled out and delivered to the battlefields unpainted. Even through the

turmoil of battle in and around Stalingrad, however, full production was

maintained through September 1942.

Throughout the inevitable shortages, disruptions, and

difficulties of the lengthy combat periods of the German offensive in the east,

the Soviets maintained a policy of no significant product changes on the

assembly lines apart from measures to reduce and simplify production and the

associated costs. Certain innovations did figure in the manufacturing process,

including a plate-hardening procedure and the introduction of automated

welding. The design of the 76mm main gun for the tank was refined to produce

the weapon from 614 parts instead of the 861 previously required. And over the

course of two years’ manufacturing, the unit cost of the tank was reduced from

269,500 rubles to 135,000, and the actual production assembly time was reduced fifty

percent by the end of 1942; this in spite of major changes to the workforce

building the tanks. Roughly half the workers had been sent to fight on the

battle front and they had been replaced by a mix of women, boys, older men, and

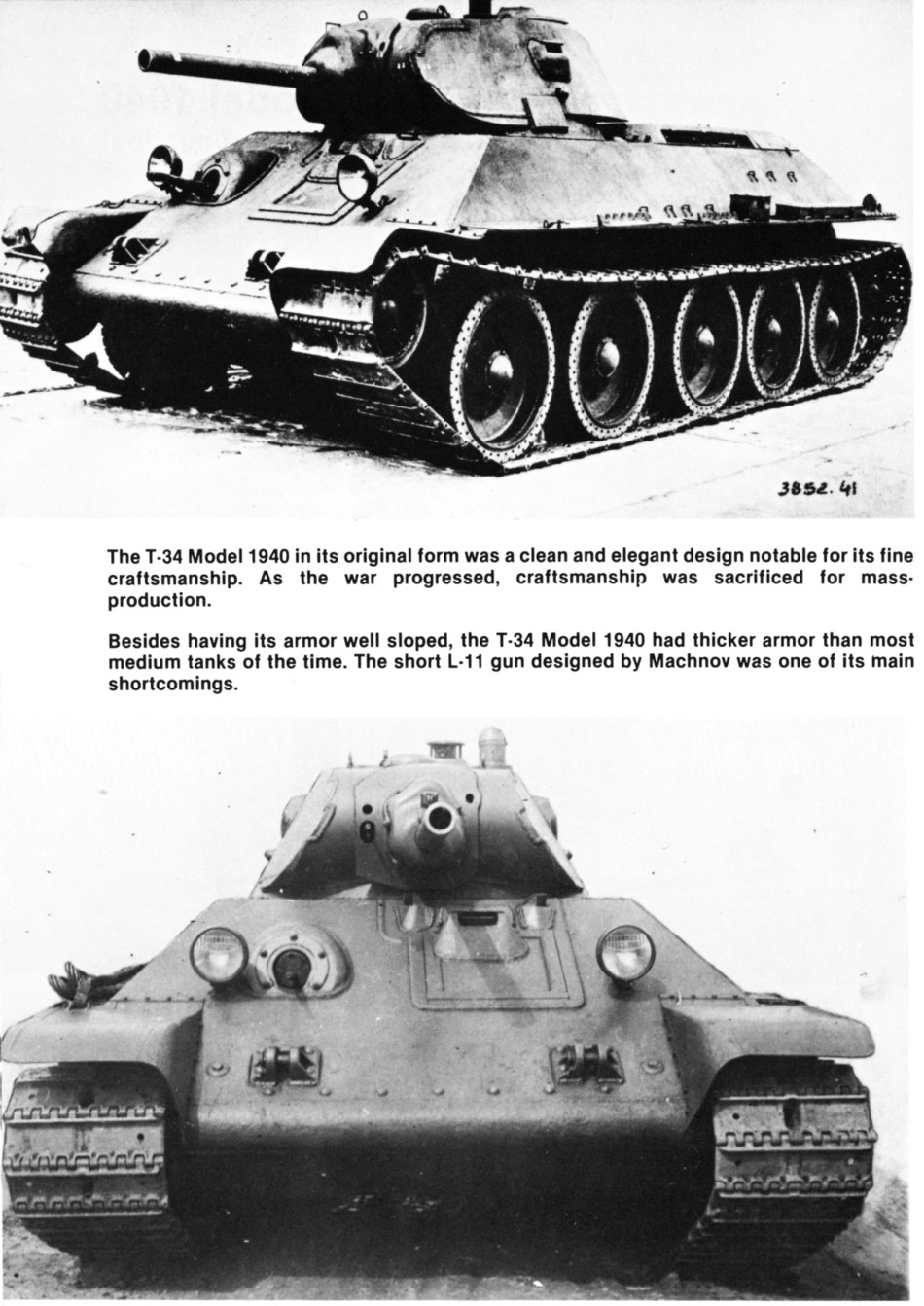

invalids. The manufacturing fit-and-finish standard dropped some from what had

previously been “beautifully crafted machines with excellent exterior finish,

comparable or superior to those of Western Europe or America.” Now the T-34 was

more roughly finished, but its quality and reliability was not compromised in

the process.

In addition to building up the Red Army’s inventory of the

tank and replacing battlefield losses, a prime goal was the improvement of

tactical efficiency of the weapon. The main emphasis was put on quickly

increasing the rate of production. A new, larger, more user-friendly turret was

designed and added to the production line in 1942, along with the addition of a

commander’s cupola for 360 degree visibility. At the same time, the desirable

rubber rims for the road wheels had to be sacrificed in favour of steelrimmed

road wheels due to rubber shortages in the Soviet Union. The engine and

five-speed transmission were improved and a new clutch was added. By 1943,

production of the T-34 had reached 1,300 a month and, like the Spitfire fighter

to Britons, the T-34 had become iconic for the Russians, symbolizing the power

and effectiveness of the Soviet counterattack against the Germans.

1941 INVASION

By the time of the German invasion of the Soviet Union on

June 22, the KhPZ and the Stalingrad Tank Factory had built about 1,226 T-34/76

tanks for the Red Army, which was roughly an equal mix of Model 1940 and Model

1941. However, at the start of Operation Barbarossa, only 5 percent of the Red

Army’s tanks were T-34s and 2 percent were KV heavy tanks, meaning that the

bulk of Soviet armored forces were still composed of obsolescent light tanks. Approximately

982 T-34/76 and 466 KV-1 tanks were deployed in the Western military districts

at the start of the invasion. Yet despite all its technical promise, the

initial combat debut of the T-34/76 in 1941 was a disaster due to inadequate

training and skimpy logistics. The T-34’s baptism of fire occurred m Lithuania

near Rassinye, when about 50 T-34s from the 3rd Tank Regiment/2nd Tank Division

mounted a clumsy counterattack against the spearheads of the 1st and 6th Panzer

Divisions between June 24 and 25. Although the T-34s caused a brief panic when

37mm AT guns failed to penetrate their armor, the Soviet attack was stopped by

a few 88mm flak guns.

General Pavlov had left GABTU to command the Western Front

just before the start of the war. Pavlov’s command included the 6th Mechanized

Corps, one of the Red Army’s strongest armored formations with 238 T-34 tanks.

Unfortunately for Pavlov, the 6th Mechanized Corps had no armor-piercing (AP) rounds

for the T-34s and only one load of fuel per tank. Due to security concerns, few

T-34 crewmen had actually been trained. The best-designed tank in the world is

merely scrap iron if it does not have ammunition, fuel, or a trained crew, and

that was the condition of virtually all the T-34 units in the summer of 1941.

The 6th Mechanized Corps and all its vital T-34s were annihilated in the first two

weeks of the war without accomplishing anything of consequence. By early July,

about half the available T-34 and KV-1 tanks had been lost as the Soviet border

armies were destroyed, and most of the remaining pre-war T-34s were lost in the

Kiev Pocket. When Pavlov’s command was wiped out in the Minsk Pocket, he was

recalled to Moscow and executed.

The T-34’s Overall Combat Results in 1941

The combat results for 1941 show the Soviets lost an average

of over seven tanks for every German tank lost. If all German fully tracked

AFVs (assault guns, tank destroyers, SP artillery, etc) and losses from

Germany’s allies are included in the German figures, then the ratio drops to

6.6 to 1 in the German favour.

Of the total of 20,500 Soviet tanks lost in 1941,

approximately 2,300 were T-34s and over 900 were mostly KV heavy tanks. Even if

the T-34’s loss ratio was better than seven for every German tank, it was still

most likely in the region of four or five to one. Frankly, if 2,300 of any new

Wehrmacht tank type had been lost within six months of its first deployment,

even with a loss ratio of one to one (let alone 0.2-0.3 to one), then most WWII

historians would have described the tank’s combat record as an unmitigated disaster.

More informed commentaries relating to the T-34’s combat

performance in 1941 consider factors such as: the T-34 tank crews had little

time to train on their machines, they had major ammunition supply problems, and

the support infrastructures were not in place to recover damaged machines.

These arguments have a lot more merit than the ‘only small numbers available’

or the ‘committed in small packets’ arguments. There is no doubt that a large

proportion of T-34s in 1941 fell victim to operational type losses, especially

in the situations the Red Army found itself in during the summer of 1941. Many

T-34s had little or no armour piercing ammunition in June 1941, although they

did in the months that followed. Many T-34s were abandoned and lost due to

breakdown, being bogged down or simply out of fuel. The Red Army’s tank

divisions, already short of tractors, had little to no recovery vehicles or

even time to recover these tanks. However, even if we assume a staggering

40-50% of T-34s were operational losses (which is probably too high an

estimate), then the T-34’s loss ratio in tactical combat is still around

two-three to one in the German favour.

The T-34’s Design Weaknesses

When one considers the apparent superiority of the T-34, the

question has to be asked: why did the T-34 consistently suffer at least a

two-three to one loss ratio against ‘inferior and obsolescent’ enemy tanks in

tactical combat, i.e. when actually shooting at each other? Either the German’s

combat proficiency was supernatural, the Soviet’s combat proficiency was

unbelievably incompetent, or there were design flaws inherent in the T-34 as a

complete weapon system which are not apparent in a cursory analysis of combat

power based on armour and gun penetration. I believe the latter to be the case.

The T-34/76’s one great weakness was its fire control efficiency. It suffered

from the same two-man turret syndrome as other Soviet tanks in this period,

namely that the tank’s commander, gun aimer, gunner and platoon commander (if a

platoon leader), were all the same person. Exacerbating this was the fact that

the T-34/76 had relatively poor main gun optics quality, no turret basket, a

very cramped and low turret (the gun could not depress more than three degrees

severely restricting use on a reverse slope or at close range), poor turret

drive reliability, no radios, and generally poor target observation and

indicator devices (including no turret cupola and only one vision periscope for

the tank’s commander). All these factors are considered in detail in

calculating a tank’s Fire Control Effect (FCE). The T-34 is discussed here as a

case history. In summary, the T-34/76’s inherent fire control efficiency was so

bad that even well trained and experienced tank crews were put at a severe

disadvantage. For inexperienced tank crews, with no radios and probably no

organised combined arms support, it was a disaster.

So what was the result of the T-34/76’s two man turret, weak

optics and poor vision devices (that is a poor overall FCE factor)? German

tankers noted “T-34s operated in a disorganised fashion with little

coordination, or else tended to clump together like a hen with its chicks.

Individual tank commanders lacked situational awareness due to the poor

provision of vision devices and preoccupation with gunnery duties. A tank

platoon would seldom be capable of engaging three separate targets, but would

tend to focus on a single target selected by the platoon leader. As a result

T-34 platoons lost the greater firepower of three independently operating

tanks”. The Germans noted the T-34 was very slow to find and engage targets

while the Panzers could typically get off three rounds for every one fired by

the T-34.

A combat account from Operation Barbarossa highlights the

problem with the T-34/76’s fire control systems and also why its overall combat

power is so overrated. “Remarkably enough, one determined 37mm gun crew

reported firing 23 times against a single T-34 tank, only managing to jam the

tank’s turret ring”. In this engagement T-34 proponents will highlight the

impunity of the T-34 to the 37mm Pak 36 AT gun. However this is hardly

surprising against a gun that can only penetrate 29mm of 30 degree sloped

armour at 500metres with ordinary AP ammunition. What is really important in

this story is that the AT gun managed to get 23 shots off, and it turns out

that the T-34 in this report didn’t even manage to hit the AT gun. Once better

AT guns appeared, which they rapidly did, T-34s would be lucky to survive 2-3

rounds. Contemporary German tank crews would have been be appalled if they let

enemy AT guns get more than two rounds off before they took defensive action.

This example highlights the difference between tanks designed to optimise all

their fire control related systems and hence maximise their firepower, and

those that weren’t.