Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Shipbuilding

Viking Longships

Havhingsten fra Glendalough in dock. The Havhingsten is a faithful reconstruction of Skuldelev 2, the second longest Viking longship ever found. Skuldelev 2: The great longship Skuldelev 2 is a war machine, built to carry many warriors at high speed. With a crew of 65-70 men, it was a chieftain’s ship, like those praised in ancient scaldic verse and sagas.…

Most Recent

Dutch Navy

De Zeven Provinciën was a Dutch ship of the line, originally armed with 80 guns. The name of the ship was also written as De 7 Provinciën. The literal translation is “The Seven Provinces”, the name referring to the fact that the Dutch Republic in the 17th century was a…

Russia’s Nuclear-Powered Icebreaker Lider

By TASS Russian news agency The icebreaker has to become operational in 2027 when the economic crisis is likely to end and the competition of the global players for Polar resources and the shortest Northern Sea Route from the Pacific to the Atlantic would resume. Historically, Russia enjoys a priority…

Russian Heavy Frigates

Capturing of Swedish 44-gun frigate Venus by Russian 22-gun cutter Merkuriy of June 1, 1789. Captured Swedish heavy frigate Venus. The spring of 1789 was marked by two single-ship actions on the part of a young Irish-born Lieutenant, Commander Roman Crown, that were to have long-term consequences for Russian naval…

Snorkel?! Part I

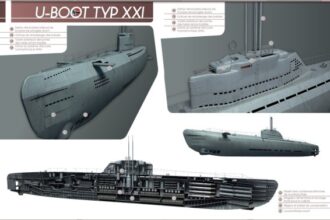

Histories of the Battle of the Atlantic universally fail to appreciate the impact that the introduction of the snorkel had on the evolutionary shift in U-boat operations at the end of the war. German U-boat histories of the Second World War are dominated by the period 1940–43 and written by,…

Snorkel?! Part II

The German snorkel device revolutionised undersea warfare. The once surface-bound submersible was turned into a ‘true’ submarine capable of remaining submerged almost indefinitely. This late-war innovation frustrated Allied intelligence and anti-submarine search technology, well into the age of nuclear power. After World War II the snorkel was introduced by all…

Chatham Royal Dockyard and Infrastructure I

Farington, Joseph; Chatham Dockyard; National Maritime Museum; http://www.artuk.org/artworks/chatham-dockyard-174538 Looking from right to left (i.e. south to north) along the river bank can be seen: the two Anchor Wharf Storehouses (with the Rope House and associated buildings behind); two shipbuilding slips (between which can be seen the Commissioner’s House with its…

Most Popular

American Civil War Ironclads

At the outset both sides were militarily weak. The North did have a clear advantage…

MEDIEVAL SHIPBUILDING

Early medieval Europeans received from their predecessors two broad ranges of wooden shipbuilding traditions, one…

Early Athenian Ships I

Athenians had been seafarers since earliest times, but their ventures were always overshadowed by maritime…