Newsletter

Get the latest from Weapons and Warfare right to your inbox.

Follow Us

Explore

Austria

Kunersdorf 1759 Part II

Battle of Kunersdorf, Alexander Kotzebue The Battle A little more than an hour after their appearance from the thick woods, the Prussian main body stood ranked for battle and had the batteries set up. Finck had been waiting for the signal to attack since first light, and his gunners were waiting with their pieces. At about 1130 hours, the Prussians…

Most Recent

Why the Austrians lost

The Battle of Marengo, Louis-François Lejeune It was the French revolutionary armies that had proved most innovating. Their striking success rested on various factors. The remarkable mobility which the French restored to warfare was crucial. It was based on the old principle, largely proscribed during the ‘age of cabinet wars’,…

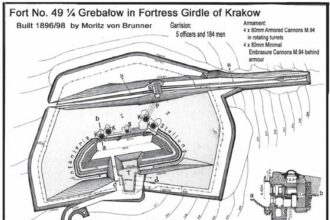

Fortifications of Austria-Hungary during the WWI

A 305mm Skoda Emma howitzer. To secure their Balkan territories, the Austrians built a variety of fortifications in the area. Some of the most unusual forts were part of the fortress defences of the ports of Pola and Cattaro where the construction programme began in the 1880s. Pola was encircled…

Steyr SK 105 Light Tank

SK 105, also known as Kürassier, was developed from 1965 by Saurer-Werke, taken over by Steyr-Daimler-Puch in 1970, to meet the requirements of the Austrian Army for a mobile antitank vehicle. First prototype was completed in 1967 with pre-production vehicles following in 1971. Driver sits front left, turret centre, engine…

War of the Mantuan Succession

The French were active in Italy. In combination with Savoy, they tried to seize Spain’s ally Genoa in 1625, only to be driven back by the Spaniards. Two years later, the end of the direct male line of the Gonzaga family produced a contested succession for the Duchies of Mantua…

Battle of Sisak 1593

Croatia 1593 Hasan Pasha, the Ottoman military Governor of Bosnia, raiding into Croatia found himself facing a large Imperial force led by Michael of Wallachia and Sigismund Bathory of Transylvania outside Sisak, on the Kupa and Save Rivers. Hasan was killed in a terrible defeat. Grand Vizier Sinan Pasha was…

Battle of Keresztes 1596

The Battle of Keresztes took place on 24–26 October 1596. The battle was fought between a combined Habsburg-Transylvanian force and the Ottoman Empire near the village of Mezőkeresztes (Turkish: Haçova) in northern Hungary. The battle ended with a victory by the Ottoman Empire. Lord Kinross, a early 20th-century historian, said…

Most Popular

WWI Austro-Hungarian Small Arms Part I

Roth-Steyr Models 1907 and 1912 Austria-Hungary finally moved to replace its aging Rast-Gasser revolvers with…

Austro-Hungarian Cavalry WWI

Pack-horse of a cavalry machine gun detachment; members of these and the telegraph detachments were…

Austria’s Opening Disasters – WWI

Austria’s decision for war against Serbia was not a product of fatalism, fecklessness, or incompetence.…

The War of Austrian Succession: 1740-1748 – In Italy

The death of the Chevalier de Belle-Isle, Battle of Assietta. In October 1740, Emperor Charles…