Karem Aircraft is a recent and little-known company in

the aerospace industry. But your story deserves attention. Founded in 2004 by

Abraham Karem, creator of the MQ-1 Predator, and based in California, the

company is one of five competitors in the US Army’s Future Attack

Reconnaissance Aircraft (FARA) program to choose a new attack and scout

helicopter.

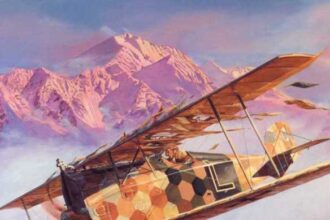

Abraham Karem has revealed a different competitor to

the FARA program. Called AR40, the advanced helicopter brings together some

interesting concepts such as rigid rotor where blade movement is independent,

with a pivoted pusher rotor. According to Karem, the AR40 uses the tail rotor

as anti-torque at slower speeds while rotating to the longitudinal position on

cruise flights. The main rotor torque in this case is nullified by a vertical

stabilizer. The AR40 has a main rotor of just 11 meters in diameter and tilting

wings with 12.2 meter wingspan. Powered by a GE Aviation T901 engine, the

aircraft has two side-by-side seats plus a four-occupant rear cabin. Karem has

partnered with Northrop Grumman and Raytheon, companies with the most

experience in providing aircraft and systems to the US government, but believes

its proposal is the most efficient and economical – capable of exceeding the

180kt speed required by technical requirements.

Karem Proposes AR40 Active-Rotor Compound Helicopter

Aviation Week & Space Technology

Graham Warwick

Mon, 2019-10-14 09:00

Karem Aircraft is offering a high-speed compound helicopter

with an actively controlled main rotor for the U.S. Army’s Future Attack

Reconnaissance Aircraft (FARA) program. The company has teamed with Northrop

Grumman and Raytheon to propose its AR40 design.

The AR40 is an active-rotor, winged, compound helicopter.

“The hallmark feature is it can fly fast,” says Thomas Berger, Karem’s FARA

program manager. “We go past the threshold requirement by about 20% and do it

without any additional auxiliary propulsion on a single [General Electric] T901

engine.”

The FARA requirements set a threshold maximum speed of 180

kt., so this implies the AR40 can reach about 215 kt. The reference to

auxiliary propulsion points to Bell’s FARA contender, the single-main-rotor 360

Invictus, which uses a supplemental power unit to achieve its 185-kt. maximum

speed.

Founded by Predator designer Abe Karem, the company is

better known for development of the Optimum Speed Tilt Rotor (OSTR). But the

Army’s requirement that FARA fit within a 40-ft. box so it can fly between

buildings in urban conflicts rules out a tiltrotor design.

The AR40 has a single main rotor, a wing, and unique

swiveling tail rotor. This provides anti-torque control at low speed, but

swivels aft to provide propulsion for higher forward speed. “This is the best

design we know to attack the requirement. It has low drag and low vibration at

high speed,” Berger says.

The model designation AR40 stands for “40-ft. active rotor.”

In a conventional rotor, a swashplate and pitch links mechanically transmit

cyclic and collective blade-pitch commands to the rotor head. In Karem’s active

rotor, the blades are individually controlled by electric actuators in the hub.

This allows blade pitch to be precisely controlled to maximize performance and

minimize drag and vibration at high speed, Berger says. Additionally, power for

the full-authority individual blade control actuators is generated within the

hub, he says, eliminating the need for slip rings to transfer electrical power

to the rotating rotor.

The main rotor has three stiff, lightweight blades and a

rigid, hingeless hub. The lack of a swashplate and pitch links results in a

slim pylon between fuselage and rotor, reducing drag. To achieve high speed,

“we reduce drag significantly and unload the rotor to the wing,” Berger says.

“The swiveling tail rotor means we do not have the edgewise drag of a tail

rotor. We store all the ordnance inside, stow the gun and fair the targeting

turret.”

Despite the emphasis on reducing drag, the AR40 has

side-by-side seating. This improves crew coordination and provides additional

room behind the cockpit for mission equipment or a cabin for personnel. “It’s

space for free,” he says.

While no active rotor has yet progressed beyond the R&D

stage, Karem is developing the component technology under the Army’s Joint

Multi Role technology demonstration (JMR TD). Under this program, the company

will ground-test a 36-ft. variable-speed rotor for its OSTR design for the

Army’s planned Future Long-Range Assault (FLRAA) replacement for the Sikorsky

UH-60 Black Hawk.

The OSTR uses the same active control, lightweight blade and

rigid hub technology as the AR40. The JMR TD rotor “is under component test,

with the integrated test next year,” Berger says. “It will directly help reduce

risk for [the AR40’s] individual blade control, rigid hub, blades, etc.”

Karem has worked with the Army’s science and technology

community for many years, first on Joint Heavy Lift and later on JMR TD, but is

still a relative unknown and so has teamed with heavyweight partners: Northrop

Grumman for airframe production and support and Raytheon for the mission

system.

“Karem is the driving pioneer of the rotor and drive system.

Northrop Grumman brings full OEM production and support capability,” he says.

Northrop company Scaled Composites is also involved, and will likely build the

prototype if the AR40 wins one of the two competitive prototype contracts to be

awarded in March.

Northrop Grumman Mission Systems will provide the avionics

and cockpit integration. Raytheon will perform mission-system integration using

its experience with modular open-architecture systems. “We have teamed with big

OEMs who have the ability to provide managed risk,” Berger says.

In addition to competing for FARA, Karem plans to respond to

the Army’s request for proposals for the two-year competitive demonstration and

risk-reduction phase of the FLRAA program, proposing its TR36 OSTR. “We are

participating in FLRAA,” says Bruce Tenney, director of military VTOL business

development. Karem is working under a one-year extension to its JMR TD

contract, which includes refining its FLRAA concept.