The basic idea of generating lift from a rotating wing can be traced back certainly to the early fourteenth century: an illuminated manuscript of this period gives the earliest known illustration of a child’s toy consisting of a fourbladed `airscrew’ mounted on a vertical spindle. This is rotated by pulling a string wrapped round the spindle, whereupon it flies into the air. Essentially the same principle is involved in a toy with two contra-rotating screws operated by a spring-bow mechanism, which was described to the Paris Academy of Sciences by Launoy and Bienvenu in 1784 during that period of acute interest in all matters aeronautical. A similar device was described by Cayley in his paper of 1809. Versions of this toy powered by clock springs were made by the Swiss Jakob Degen in 1816, and by several later inventors.

In 1842 an English engineer, W. H. Phillips, flew a model which was driven by jets of steam (generated by the heat from a form of chemical firework) from the rotor-tips, and in 1863 the Vicomte Ponton d’Amecourt built a model helicopter powered by a conventional reciprocating steam engine which was probably too heavy to fly. The Italian engineer Enrico Forlanini succeeded in flying a similar model for 20 seconds in 1877 by the expedient of pre-heating the boiler before attaching it to the model.

The first serious attempts to build a full-size piloted helicopter were made in France in 1907, by Louis Breguet and Paul Cornu, who were both aiming for a 50,000-franc prize offered for the first one-kilometre flight. Breguet’s machine had four biplane rotors, driven by an 18kW (24hp) Antoinette engine. In September 1907 it hovered for a minute, but was stablized by four assistants holding the machine’s four corners. Cornu’s machine also had an Antoinette engine, driving two sets of two-bladed rotors; when tested in November it successfully hovered just above the ground for several minutes. Two months later the prize was won by Farman’s flight on a fixed-wing Voisin, and Breguet and Cornu both abandoned their efforts; Breguet turned his attention to fixed-wing machines.

For the next thirty years, a considerable number of inventors attempted to make a practical helicopter, with no significant success. As an alternative to the power-driven rotor, the Spaniard Juan de la Cierva produced an aircraft which he called the autogiro. This was a machine on which lift was produced from a rotor which was rotated after the manner of a windmill as the aircraft was pulled through the air by a conventional engine and propeller. In 1923, Cierva built a machine with hinged rotors, free to flap up and down as they rotated, which provided a simple solution to the unbalanced lifting force generated when the rotor was in forward flight. (On one side of the rotor disc, the blade is moving forward relative to the aircraft; on the other side it moves backwards. Adding the forward motion of the aircraft, one blade is moving much faster than the opposite one, and therefore generates more lift unless the incidence is reduced on the advancing blade.)

Cierva was subsequently funded by the British Air Ministry to produce a number of designs which were built in some numbers in Britain, France, Germany and the USA, and the Cierva C. 30 model was used for civil and military purposes on a fairly small scale from 1935. Later models of autogiro have been made, mainly as single-seat sports machines, but this type of aircraft has never found a realistic practical use.

One of those who took a licence to build Cierva machines was the German Focke-Wulf company, whose founder, Heinrich Focke, produced the first practical helicopter in 1936, using the hinged rotor system. To counter the torque effect of a power-driven rotor, Focke employed two counter-rotating rotors on outriggers from a basically conventional fuselage. The engine in the nose drove a conventional propeller for forward flight, and also drove the two rotors through bevel gears and inclined shafts. The practicality of Focke’s Fw61 helicopter was demonstrated by a 110km (68 mile) cross-country flight in 1938, and by public demonstrations inside the Berlin Sporthalle.

Focke produced a larger development of the Fw61 in 1940, and another German engineer, Anton Flettner, produced a practical helicopter which was built in small numbers for the German Navy, but wartime priorities lay elsewhere and neither design found significant practical application. Parallel work in other countries produced working prototypes by 1940; by far the most significant was Igor Sikorsky’s VS-300 in the USA, which passed through a variety of configurations to its final successful form in December 1941. A single three-bladed rotor with hinged blades was used to generate lift and, by tilting the rotor disc, forward propulsion, and a small rotor with horizontal axis facing sideways served to counter the torque and acted as a rudder. Sikorsky’s configuration has continued to dominate helicopter design to the present day. Although a variety of counter-rotating twin-rotor designs have also been brought into large-scale production, probably 80-90 per cent of all the helicopters built have employed a single rotor and an anti-torque tail rotor.

Helicopters were normally powered by conventional aircraft piston engines (with modified lubrication systems and additional cooling fans) until the 1950s, but then gas turbines were introduced, first by the French company Aérospatiale in 1955. These engines were designed to have a turbine stage driving the rotor through a gearbox-colloquially known as a turboshaft engine. The main advantage was the lower vibration level and greater reliability of the gas turbine and, as in other aircraft applications, the gas turbine has supplanted the piston engine for all but the lowest-powered helicopters.

The helicopter rotor of the 1940s and 1950s was a complicated piece of machinery: the blades were hinged to allow a limited degree of motion at their roots about all three axes, and a variety of springs and friction dampers were employed to allow the blade angles to be varied appropriately. Subsequent development has replaced mechanical hinges and bearings by elastomeric hinges, employing plastic materials with tailored properties of strength and flexibility. Aérospatiale introduced their Starflex rotor hub, in which the three conventional hinges are replaced by a single ball joint of rubber and steel sandwich construction, into their AS350 Ecureil in 1977. At the same time, glass fibre and carbon-fibre composites have been introduced for construction of the rotor blades.

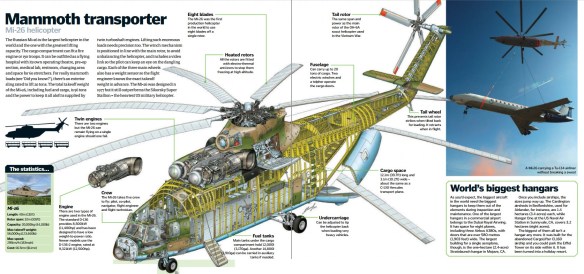

The ability to land and take-off vertically enables the helicopter to perform a wide variety of duties, but its mechanical complexity compared to a fixed wing aircraft leads to higher costs, so the major users have always been the military. Apart from being used as troop transports and for casualty evacuation, they are used widely for observation work and for ground attack against infantry and armour. Civilian uses include passenger carrying into confined spaces (oil-rig platforms, city-centre roof-top terminals, hospitals, and the like), pipe-line patrols, and specialized crane-type operations. Typically, the Boeing-Vertol 234 carries up to 44 passengers for up to 800km at 250kph (500 miles at 155mph), and the largest production helicopter in the world is the Russian Mil Mi 26 with 20,000kg (44,000lb) payload.

#

The period between World War II and the early 1960s brought the helicopter into world prominence, both as a modern weapons system and a civilian workhorse. Whether plucking wounded soldiers and Marines from craggy ridgelines or downed aircrewmen from the freezing waters off the coast of the Korean peninsula, the renown earned by U. S. “choppers” substantiated the versatility, and unquestioned practicality, of rotary-wing aircraft. From the frozen vastness of Siberia, to the steaming mountains and jungles of Indochina, to the deserts of North Africa, helicopters performed tasks outside the capabilities of conventional fixed-wing aircraft. Rotorcraft, once considered tangential gadgets, earned esteem from skeptical military and civilian leaders by completing previously unimaginable tasks.

Operating in combat situations and such diverse climatological environments, however, exposed numerous shortcomings of the fledgling helicopter industry. Technology limited helicopter performance in many areas. Heavy reciprocating engines limited available power, thus reducing speed and the maximum gross weights of rotorcraft. The lighter turbine engines, with more power-to-weight efficiency, ameliorated that problem. The turbine-powered Kaman 225 proved this when the helicopter climbed to 10,000 feet and the turbine operated so efficiently that the test pilot had to close the throttle and autorotate to a lower altitude. At high altitudes the helicopter continued to climb at idle power. The turbine also reduced the noise levels in helicopters to just a turbine whine and the noise of the rotor blades. In 1955, Lycoming introduced the T-53 series gas turbine engine designed especially for installation in helicopters, which resulted in machines designed especially for power and speed. Helicopter engineers in Europe and the USSR also made use of the benefits of turboshafts in their helicopters.

Metallurgy also increased the efficiency and durability of helicopters. Revolutions made in manufacturing fixed-wing aircraft during World War II were adapted to helicopters. Helicopters produced with lightweight aluminum and magnesium alloy skins and frames could lift larger loads. Metal rotor blades replaced laminated wooden blades, increasing both lift and resistance to the elements. Lighter airframes also allowed for the installation of self-sealing fuel tanks and armor for the crew and critical engine parts, which had proved extremely vulnerable to groundfire in early machines.

Nascent industries on both sides of the Iron Curtain (NATO and the Warsaw Pact) vied with one another to produce the most efficient and deadly helicopter on earth. Military planners demanded larger and more powerful rotorcraft, capable of surpassing the capabilities of all their adversaries’ helicopters. Generals and admirals yearned for helicopters powerful enough to attack an enemy’s troops, planes, and ships. Helicopter innovators readily complied with these requests because of the financial rewards and the personal satisfaction involved.

Additionally, helicopters took on new roles in the civilian market. The undisputed success of air ambulances in Korea laid the foundation for the boom in civilian EMS helicopter services in the latter half of the twentieth century. Civilian helicopters, usually modified from military designs, offered passenger service in areas never previously served. Helicopters carried petroleum engineers, drilling and construction crews, and loggers into the most unimaginable sites throughout the world. Helicopters also became television and movie stars. In the 1950s the TV series Whirlybirds was based around the Bell 47. Moviemakers also realized the great versatility of the helicopter as a camera platform and used the machines to shoot scenes never before thought possible. Newspaper publishers saw the benefits of sending reporters out in helicopters to “scoop” the competition. The Chicago Tribune bought a Bell 47, becoming the first U. S. newspaper to own its own helicopter.

Although no market materialized for the “everyman helicopter,” helicopters played a role in the financial recovery after World War II. Military and civilian operators from around the world placed orders with helicopter manufacturers, increasing the companies’ profits and providing thousands of additional jobs for both white- and blue-collar workers. Fortunately for both military and civilian operators, helicopter designers and manufacturers looked to the future, which would place even greater demands on their aircraft.