Arguably, the Focke-Wulf Fw 190 evolved into wartime Germany’s most effective fighter, offering the Luftwaffe the benefit of manoeuvrability combined with stability as a formidable gun platform and the flexibility to perform as an air superiority fighter, a heavily armed and armoured interceptor and as an ordnance-carrying ground attack aircraft. However, this superlative machine had its Achilles’ heel, for when the first Fw 190A-2s entered operational service with Stab/JG 26 and I./JG 26 on the Channel Front in July 1941, it became apparent quite quickly that the type’s performance at high-altitude was weak.

The Fw 190A-2 was powered by the 1,500hp BMW 801C-1 and 1,600 hp C-2 radial engines. From the start, and during initial testing in 1940 and early 1941, this engine was plagued with faults. Crews and technicians of the Luftwaffe’s dedicated test unit Erprobungsstaffel 190 at Rechlin, therefore, were forced to undertake considerable trouble-shooting. Finally, by August 1941, the engine was deemed safe enough to allow the first Fw 190A-1 production machines to be handed over to 6./JG 26, which at the time was based in Belgium. Unfortunately, the problems persisted, with nine Fw 190s crashing in August–September 1941. The finger of blame was pointed at BMW, whose engines continued to be plagued by overheating and compressor damage.

There were also delays in deliveries associated with failings afflicting the anticipated 1,700hp BMW 801D. This engine, fitted in the Fw 190A-3 (in production from late 1941), benefited from uprated power achieved by increasing the compression ratio in the cylinders and refinements to the two-speed supercharger. Nevertheless, it was found to suffer from a fall in performance above 19,750ft.

Despite this worrying scenario, since early 1941 Kurt Tank had been working on a re-design of the Fw 190 that would incorporate a different powerplant capable of functioning effectively at altitudes higher than those then achievable. In his post-war memoirs, Tank summarises succinctly the prevailing situation at the time:

Hardly was the Fw 190 flying at the beginning of the war before it had to be extensively redesigned, enlarged and made more powerful still. In no time at all, the requirements of very many pieces of auxiliary equipment connected with the armament and communications of the plane forced up its weight, and at the same time new and more powerful engines were becoming available.

In November 1941, under the project designation ‘Ra-8’, Focke-Wulf decided to install a Junkers Jumo 213A inverted V12 engine into the airframe of an Fw 190, while tests also proceeded with a Daimler-Benz DB 603 inline inverted V12 – this option was ultimately dropped in favour of the Jumo unit. The Jumo 213’s edge came in the form of a pressurised cooling system and, with high boost settings, was designed to produce 1,750hp at 3,250rpm. In a clever move, the Junkers design team placed the mounting points in exactly the same locations as those for the DB 603. Although this meant easy interchange, the supercharger intake was to be found on the left side of the DB 603, while in the case of the Jumo it was on the right. The Jumo 213 also had a strengthened crankshaft and engine block, with smaller external dimensions than the Daimler-Benz motor, although it did retain the same bore and stroke.

The first aircraft to be fitted with a Jumo 213A was Wk-Nr. 0039 CF+OX, which was prototype V17. This Fw 190, with its ‘Langnase’ (‘long nose’) as a result of the engine installation, also featured a tail unit that was similar in shape to what would appear in the later Ta 152 high-altitude interceptor. It took to the air for the first time on 26 September 1942 from Hannover-Langenhagen, flown by Focke-Wulf chief test pilot Flugkapitän Hans Sander. There were some initial teething problems with the installation, and after Kurt Melhorn had made the eighth test flight in V17 on 4 December 1942, he reported that ‘the engine is still running very roughly so that proper testing cannot be carried out.’ In January 1943 the aircraft was returned to the workshops for fitting with a pre-production Jumo 213A-0.

Focke-Wulf persisted with the trials throughout 1943, Sander completing three test flights in V17 on 27 February, for example. The aircraft had its radio equipment removed and replaced by a ballast load of 290lb, with 26lb in the tail fin and 33lb in the jacking tube. Unfortunately, extreme vibration made the machine impossible to fly, casting heavy doubts over any chance of it becoming a combat-ready fighter since, primarily, such vibration would greatly hamper use of a reflector gunsight. More flights were undertaken in March by Sander, his fellow test-pilot Bernhard Märschel and Hauptmann Otto Behrens, a Luftwaffe fighter technician from Rechlin. Still the Jumo was viewed as unfavourable compared to the earlier BMW engine, despite the fitting of new bearings. Beside long-running coolant leaks, oil was now found to be routinely seeping onto the floor of the cockpit when the aircraft was aloft.

On 30 April V17 was transferred to Rechlin for further assessment in the hope of solving these problems. It was discovered that the vibration was caused by crankshaft resonance in the continuous speed range, and a solution was soon found in the form of a spoke wheel inserted between the crankshaft and the propeller. This duly shifted the resonance into an rpm range that was not disruptive. A change in the cylinder firing sequence reduced vibration levels even further, although this in turn reduced the engine’s performance by a full eight per cent because the exhaust and intake lines had been optimised for the original firing sequence. Nevertheless, by June 1943, the 185 engines thus far completed at Junkers’ Dessau plant had been modified accordingly.

During the summer V17 returned from Rechlin to Focke-Wulf, where it was fitted with a Jumo 213A-1 and a streamlined cowling but still lacked armament.

The technical issues surrounding the Jumo powerplant persisted for more than a year, prompting General-Ingenieur Wolfram Eisenlohr, head of the engine department in the RLM, to lament:

The neglect under which matters of engine development have long suffered have now led to a critical lack of developmental capacity. A glance at other countries shows that research into powerplant matters abroad have been handled much more favourably than here.

In May 1944 V17 was refitted with a Jumo 213A-2 that drove a wooden VS 9 propeller. The Junkers engine was some 24 inches longer than the BMW 801, which meant the aircraft had to be modified at the Focke-Wulf plant at Adelheide in late April. Its fuselage was extended by 20 inches just ahead of the tail assembly to offset this. In this configuration, the machine became V17/U1 – the first true Fw 190D-9 prototype. Testing went reasonably well, with Märschel completing the inaugural flight on 17 May when he flew it back to Hannover-Langenhagen. Here, it underwent extensive trials, with test pilots generally reporting that the Jumo 213A offered a great improvement at altitude over the BMW 801D. Furthermore, thanks to the D-9’s reduced drag as a result of its a narrower radiator profile, it was faster than the radial-engined Fw 190 in a dive.

In a further stage of development, in June–July 1944, because of ‘difficulties with existing prototypes’, the airframes of two early Fw 190A-8s were reconfigured under the suffix D-9 (‘D’ being given the moniker ‘Dora’) – a designation that seems to have first been used in a Focke-Wulf drawing dating from January 1944. These aircraft were to be made available ‘immediately’ at Adelheide under the prototype numbers V53 and V54. The Fw 190A-8 variant was by far the most numerous and most potent Focke-Wulf heavy fighter to be built, and it became the Luftwaffe’s main close-range interceptor for operations against USAAF heavy bombers throughout 1944–45.

The January 1944 drawing incorporated an extended fuselage and tail assembly, along with strengthening of the forward fuselage and wing centre section and provision for a Jumo 213A engine.

The first to be converted was Wk-Nr. 170003, the third A-8 to be built, which became V53 (coded DU+JC) in the D-9 programme. However, this prototype was fitted with a Jumo 213C at the Focke-Wulf plant at Sorau, in Silesia. Essentially an A-model Jumo engine with rearranged secondary equipment (such as supercharger and oil pump), it was capable of, and designed from the outset for, the fitment of a centreline cannon firing through an opening for a blast tube in the propeller hub. This had the advantage of a gun being more along a pilot’s line of sight, as well as offering less impact on speed and manoeuvrability. A disadvantage, however, was the recoil associated with a centrally-mounted weapon and the impact it had on the engine, leading to potential mechanical problems and possible damage.

When the aircraft made its first flight on 12 June 1944, it retained the original A-8 wing armament comprising four 20mm MG 151/20E cannon and a pair of 13mm MG 131 machine guns mounted over the engine. Testing of V53 was rigorous, with no fewer than 100 flights being made before it was eventually reassigned as an armaments test aircraft for the new Ta 152B-5, at which point it became V68.

Fw 190A-8 Wk-Nr. 174024, coded BH+RX, was an aircraft that had suffered some damage on 29 May. Reconfigured as D-9 V54, its maiden flight took place on 26 July 1944 and its last on 4 August at Focke-Wulf’s Langenhagen plant when it was flown by Flugkapitän Sander. The main task of V54 was to trial the MW 50 methanol-water power-boosting system, for which a 115-litre tank was installed. There is some documentary evidence to suggest that the original plan was for V54 to test the GM-1 nitrous oxide-based injection power-boosting system developed by Otto Lutz in 1940.

MW 50 was a solution of 50 per cent methanol, 49.5 per cent water and 0.5 per cent anti-corrosive fluid, the liquid being injected directly into the supercharger for limited periods not exceeding ten minutes. In air combat, the boost increased the power of a Jumo 213 engine by at least 300hp to 2,000hp for short periods. Such a system came with the added benefit of needing only the installation of purpose-made spark plugs to modify the engine. However, its one side-effect was that the corrosive nature of methanol reduced engine life.

Production of the Fw 190D-9 was planned to commence in August, but on the 5th there was a setback when both the A-8 conversions were damaged as a result of an American bombing raid on Langenhagen. V53 escaped with light damage rated at five per cent, but V54 suffered 80 per cent damage and was written off. Nevertheless, series production did start at Focke-Wulf’s Cottbus and Sorau plants later in the month, as well as at the Gerhard Fieseler Werke at Kassel-Waldau and at the Ago Oschersleben and Arbeitsgemeinschaft Roland plants. The first production machines rolled out of the assembly halls at Sorau towards the end of August, with Sander taking Wk-Nr. 210001 TR+SA up on the 31st, while Hauptmann Schmitz flew the second example, Wk-Nr. 210002 TR+SB, on 15 September. Both aircraft did suffer from minor teething problems, but series production was now underway.

Having been repaired after the August attack on Langenhagen, V53 had had its outboard wing MG 151s removed and the two inboard weapons replaced by 30mm MK 103 cannon by late 1944. In such a configuration the aircraft was redesignated V68. V17 was still available for testing, despite its ‘official’ testing life having ended on 6 July at the Erprobungsstelle at Rechlin. Wk-Nr. 210001 was fitted with two MG 131 machine guns above the engine and two MG 151 cannon in the wing roots. Problems were still being experienced with the Jumo 213A-1, however. The second machine to be turned out, Wk-Nr. 210002, had the same armament and took to the air on 15 September flown by Hauptmann Schmitz. It was found during subsequent tests in this aircraft that ‘while climbing at combat power, with all flaps set to flush at 9,000m [29,500ft], an increase of over 2m [6.5ft]/sec in the rate of climb, as well as an increase of the service ceiling to 10,500m [34,500ft], could be obtained.’

In one test to measure engine temperature during a climb in Wk-Nr. 210001 at Langenhagen on 20 October, it was noted that:

The radiator coolant inlet and outlet temperatures, as well as the lubricant and supercharger air temperatures at the engine entrance, were taken using combat power climb with 20 degrees angle radiator flap opening. Since the last flight had to be broken off because of weather and engine breakdown, the height of peak temperature was just reached at 6000m [19,685ft] altitude.

Teething problems persisted, however, as illustrated by a report prepared at Langenhagen on 24 October:

As delivered, substantial gaps were present in the engine, in particular in the connection from the cowl to the wing. In order to check for their influence on level speeds, performance comparison flights were carried out in the low supercharger range, before and after sealing of all existing gaps. After conclusion of the trials in the initial condition, an even gap width at the transition from the cowl to the wing had to be ensured, first by shifting of the lower engine cover against the propeller direction of rotation, since substantial differences arose by the engine torque in flight. Then the sealing of the fairing was made by means of rubber gaskets and metal strips.

Nevertheless, as production stepped up at Cottbus and Sorau, plans were made to manufacture four D-9s per day, but such a scale of output would not be reached until November, when, in addition to the Focke-Wulf, Fieseler and Roland plants (Ago was eventually dropped from the programme), Mimetall at Erfurt-Nord was added. The first Fw 190D-9 to be delivered to an operational Luftwaffe unit was Wk-Nr. 210003.

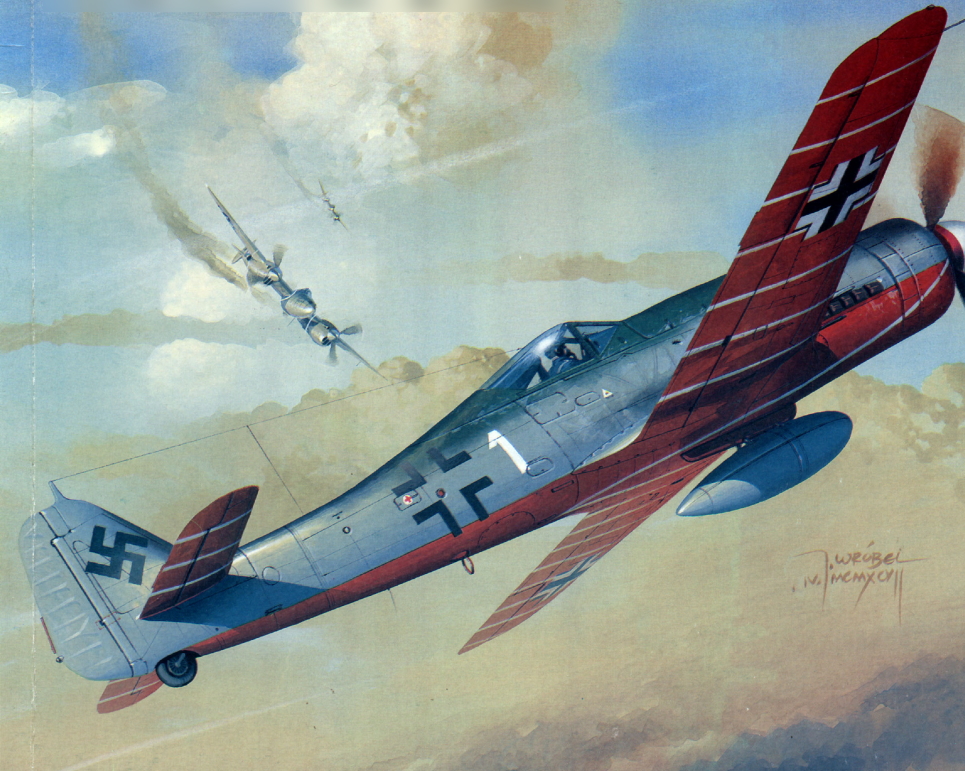

It was not until December 1944 that this aircraft saw operational service. The Junkers Jumbo 213A-1 engines produced an amazing 2242hp at sea level and had a methanol injection system as well. The speed at 20,000 ft was 426mph and at sea level it was 327mph. The climb rate was quite impressive from sea level to 32,000-ft it took only 7.1 minutes.

Even though the FW190D-9 “Langnasen-Dora” shared parity with many allied fighters, it also suffered heavy losses, both in the air and on the ground. Many inexperienced and poorly trained pilots, were no match and were at the mercy of the allied pilots with a great deal of flying time and combat experience.

Kurt Tank had designed this model to operate as a high-altitude fighter but the cabin design was unable to provide adequate pressurization. The aircraft was used to replace The FW 190A at lower altitudes and coincidentally was sometimes humorously referred to as “Downstairs Dora” or “Maid”.

Pilots that flew the FW 190A were somewhat distrustful and apprehensive to switch over to the new FW 190D-9 with its liquid cooled engine. Once these seasoned and operational pilots became accustomed to this new breed of fighter, they soon regarded it to be the best piston-engine fighter to serve with the Luftwaffe in World War II.