MG-34

MG-42

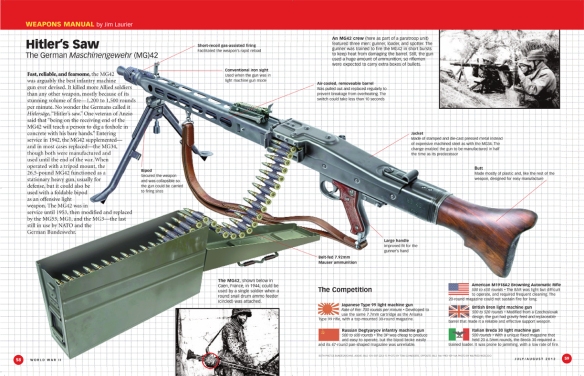

The MG-42 was designed during World War II as a replacement for the multipurpose MG-34, which was less than suitable for wartime mass production and was also somewhat sensitive to fouling and mud. It was manufactured in great numbers by companies like Grossfuss, Mauser-Werke, Gustloff-Werke, Steyr-Daimler-Puch, and several others. It is estimated that more than 400,000 MG-42s were manufactured during the war, and it was undoubtedly one of the best machine guns of World War II. It was designed to be reliable and cheap to manufacture; the design was so effective that it is still in production in more or less modified form in many countries.

Although the German Army of 1939 was not an entirely mechanized force (the German infantry was still largely foot-mobile), the hallmark of the blitzkrieg was fast-moving offensive operations characterized by speed, firepower, and sudden, overwhelming force. During these types of operations, the machine gun ceased to be a specialized weapon and became instead an integral part of the firepower needed to overcome the enemy at the point of attack. The infantry’s need for a sustained-fire weapon that soldiers could carry into battle on the attack was one of the parameters that drove the development of both the German light machine gun and the submachine gun. German tactics were built around the small team armed with light automatics. This gave a small force the firepower advantage and the ability to move rapidly and overcome opposition quickly with a large volume of self-contained automatic fire.

Such tactics demanded a new approach to the tactical use of the machine gun. Built around the interwar technological innovations by German armament manufacturers and the tactical and doctrinal transformations of the Wehrmacht, the new concept was called the Einheitsmaschinengewehr (Universal Machine Gun) or what would eventually be described as the general-purpose machine gun. The medium was too heavy and immobile to fit the new German style of warfare. In determining how to produce weapons, the Germans decided to do away with the distinctive MMG- and LMG- designs. Rather than further develop one machine gun for the sustained-fire role and another for the squad’s automatic weapon, one machine gun would be expected to fulfill all these tasks and others. Given a tripod, it would serve in the sustained-fire mode, much like a heavy at the beginning. Fitted with a bipod, it would serve as the squad’s standard automatic. The gun could also be fitted on tanks and armored cars and even aboard ships for naval air defense and on light vessels and submarines. The initial German effort to meet the general-purpose needs was the MG-34. The MG-34 entered service in 1934, the plan being to replace the collection of existing machine guns in the German Army under the one-gun-fits-all approach. The designers set out to produce the perfect weapon, demanding a higher-quality finish and precision manufacturing than was necessary. Ironically, however, the very quality of the MG-34 caused problems. Though it was superbly engineered, the resulting manufacturing process was slow, and German munitions officials anticipated that they would have difficulty replacing MG-34s lost in battle, much less produce enough to replace all the German machine guns in the Wehrmacht inventory, even with five factories working three shifts per day. Additionally, the fine tolerances made it difficult to maintain, vulnerable to poor conditions, and susceptible to stoppages caused by sand and dust.

New Production Methods

By 1937, with war clouds gathering, the German Army became concerned that enough MG-34s could be manufactured to meet the increased demand. Accordingly, three companies-Grossfuss Metal-und-Lackierwarenfabrik of Doblen, Rheinmetall-Borsig of Sommerda, and Stubgen of Erfurt-were asked to submit designs for a new gun to replace the MG-34 that would be easier and quicker to manufacture in great numbers. Rheinmetall and Stubgen submitted gas-operated designs, and Grossfuss proposed a recoil-operated design. Interestingly, Grossfuss, which had no previous experience in weapons manufacture (the company’s main line was sheet-metal lanterns), came up with a unique roller-locked breech mechanism that was both simple and resistant to dirt and dust. Ernst Grunow, a design engineer with Grossfuss, knew nothing about machine guns, but he specialized in the technology of mass production, including metal stamping and pressing. Grunow took six weeks off and attended an army machine gunner’s course in order to familiarize himself with the actual handling of such a weapon. He wanted to know what the users thought was important in a machine gun. He then returned to his office and designed a machine gun built around an earlier Mauser operating system, incorporating lessons from his stay with the machine gunners and other lessons learned during the first years of the war. The other designs were eliminated, and production began on the MG-39/41, as it was designated. By late 1941, large-scale trials were conducted, and after favorable reports all around the weapon was adopted as the MG-42 early the following year.

This design was specifically engineered for quick and cheap manufacture. The MG-42 was made from steel stampings and pressings rather than machined from solid block. It used rivets and spot welds, rather than fine finishing like the MG-34. As a result the cost of the weapon was cut significantly; more important, the manufacturing time was reduced by 35 percent. The MG-42 was to become one of the finest machine guns of all time, combining simplicity, ruggedness, and reliability with the firepower of the MG-34.

The MG-42 incorporated innovative approaches. It used a new form of delayed-blowback action, partly developed from a Polish design obtained when that country was overrun in 1939. It also had a plastic butt and pistol grip. The design also included a quick-change barrel system that permitted a well-trained gunner to exchange barrels in a matter of seconds during combat. The gun had a phenomenal rate of fire-more than 1,200 rounds per minute-far higher than any other machine gun fielded at the time. Because of its light weight, the increased rate of fire meant that accuracy was reduced. However, the Germans were prepared to accept this limitation because they theorized that a machine gunner had only a few seconds to fire at enemies before they took cover. Therefore, it was thought that the more rounds one could fire in this time, the more enemy casualties one could cause.

The MG-42 proved deadly effective and fit perfectly in the GPMG- role required by German tactical and operational concepts; it would see extensive service on the battlefields of World War II. The standard German infantry battalion employed twelve MG-42s in the schwere (heavy) role mounted on a tripod. It would prove particularly effective when the German Army was forced on the defensive late in the war. MG-42s were also used as armament on virtually every German armored vehicle, from halftracks to Panzers. Regardless of its role, Allied soldiers who faced the MG-42 will always remember the terrifying sound (“like ripping canvas”); the MG-42 was deadly and effective in the hands of German infantry.

While the MG-42 was being developed, the German Army continued work on other designs in case the MG-42 design never materialized as a viable weapon. Part of this effort was in improving the MG-34 design. The MG-34/41 was a radical modification of the MG-34 design that was no longer capable of using the spare parts provided for the original MG-34. In that sense, it was entirely new. However, by the time that the MG-34/41 was perfected, the MG-42 had arrived on the scene and proved superior to anything the German Army faced. Therefore, the MG-34/41 was abandoned, and further machine-gun development in Germany virtually ceased for the rest of the war.