VARIANTS

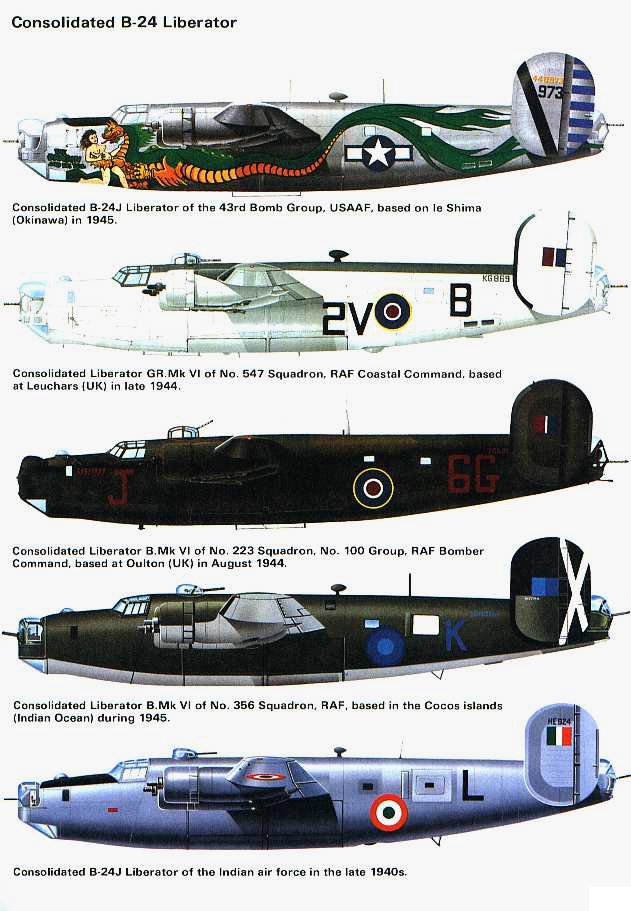

Mass production of the Consolidated Liberator was brought into full force by 1943 with the aid of the Ford Motor Company through its newly constructed Willow Run facility, where peak production had reached one B-24 per hour and 650 per month in 1944. Other factories soon followed. The B-24 ended World War Two as the most produced Allied heavy bomber in history, and the most produced American military aircraft at over 18,000 units, thanks in large measure to Henry Ford and the harnessing of American industry. It still holds the distinction as the most-produced American military aircraft. The B-24 was used by several Allied air forces and navies, and by every branch of the American armed forces during the war, attaining a distinguished war record with its operations in the Western European, Pacific, Mediterranean, and China-Burma-India Theatres.

The B-24’s long operating range made it suitable for other duties including maritime patrol, anti-submarine patrol, reconnaissance, tanker, cargo hauler, and personnel transport which brought forth a whole range of variants and subtypes, some with official designations,

XB-24 (Consolidated Model 32) – Designed in 1938 as an improvement on the B-17 Flying Fortress, at the request of the Army Air Corps. It had a wing specially designed for a high aspect ratio, tricycle landing gear, and twin vertical stabilizers. The XB-24 was ordered in March 1939 and first flew on 29 December 1939.

YB-24/LB-30A Pre-production prototypes – Only six were built, to virtually the same standard as the YB-24, including the short nose. The aircraft had originally been ordered by the French, but after the fall of France that order had been taken over by the Royal Air Force. The first six aircraft were delivered as the LB-30A. This aircraft was powered by the 1,200 hp Pratt & Whitney R-1830-33C4-G engine, giving it a top speed of 280 mph and a service ceiling of 27,000 ft. The six LB-30As were provided with six 0.303in machine guns in the nose, waist and tail positions. However, they lacked self sealing fuel tanks.

The first LB-30A made its maiden flight on 17 January 1941 before being delivered to the RAF at Montreal, the first machine reaching the UK on 14 March 1941. The RAF decided that the lack of self sealing fuel tanks meant that the aircraft could not be used over Western Europe, and so all six were handed over to Ferry Command. Their guns were removed and cabin heaters and a passenger oxygen supply were installed. They were then used to ferry RAF pilots west across the Atlantic, from where they would return at the controls of American produced aircraft. The first westwards flight began on 14 May 1941.

B-24 – Service test version of the XB-24, ordered on 27 April 1939, less than thirty days after the XB-24 was ordered and before its completion. A number of minor modifications were made, including elimination of leading edge slots, addition of de-icing boots.

B-24A/LB-30B – Ordered in 1939, the B-24A was the first production model. Due to the need for heavy bombers, the B-24A was ordered before any version of the B-24 flew. The main improvement over the XB-24 was improved aerodynamics, which led to better performance. Some were sent to the UK under Lend-Lease as LB-30B.

XB-24B – When the XB-24 failed to reach its projected top speed, the Pratt & Whitney R-1830-33 radials rated at 1,000 hp (746 kW) it carried were replaced with R-1830-41 turbo-supercharged radials rated at 1,200 hp (895 kW), increasing its top speed by 37 mph (59 km/h). The engine cowlings were made elliptical to accommodate the addition of the turbo-superchargers. The XB-24B version also lacked the engine slots of the original.

B-24C – Conversion of the B-24A using turbosupercharged R-1830-41 engines. To hold the supercharger and the intercooler intake, the cowlings were made elliptical and the new items added on the sides. The tail air gunner position was improved by adding a hydraulically powered Consolidated A-6 turret with twin .50 calibre machine guns; a Martin power turret was added to the forward fuselage. were the aircraft being produced by Consolidated.

B-24D – First model produced on a large scale; ordered from 1940 to 1942, as a B-24C with R-1830-43 supercharged engines. The D model was initially equipped with a remotely operated and periscopically sighted Bendix belly turret, as the first examples of the B-17E Flying Fortress had used, but this proved unsatisfactory in service and was discontinued after the 287th aircraft. Production aircraft reverted to the earlier manually operated ‘tunnel’ mounting with a single .50 calibre machine. The tunnel gun was eventually replaced by the retractable Sperry ball turret, which had also been adopted by the later B-17Es. In late B-24Ds, ‘cheek’ guns were added.

B-24E – A slight alteration of the B-24D built by Ford, using R-1830-65 engines. Unlike the B-24D, the B-24E retained the tunnel gun in the belly. The USAAF used the B-24Es primarily as training aircraft since this model was not current in armaments and other technology as B-24G-1 – Designation for North American-built version of the B-24H. Most B-24G aircraft were delivered to the 15th Air Force in Italy.

B-24H – Because of obvious vulnerability of the B-24 to head-on attack, the B-24H design incorporated an electrically powered Emerson A-15 nose turret. Approximately 50 other airframe changes were made, including a redesigned bombardier compartment. The tail turret was given larger windows for better visibility and the Martin A-3 top turret received an enlarged ‘high hat’ dome. The waist gunner positions were enclosed with plexiglas windows and offset to reduce mutual interference between the gunners during battle. Most H model aircraft were built by Ford at the Willow Run factory.

B-24J – The B-24J was very similar to the B-24H, but shortages of the Emerson nose turret required use of a modified, hydraulically powered Consolidated A-6 turret in most J model aircraft built at Consolidated’s San Diego and Fort Worth factories. The B-24J featured an improved autopilot (type C-1) and a bombsight of the M-1 series. B-24H sub-assemblies made by Ford and constructed by other companies and any model with a C-1 or M-1 retrofit, were all designated B-24J. The J model was the only version to be built by all five factories involved in B-24 production.

XB-24J – The deterioration of the B-24’s operational suitability concerned the USAAF sufficiently for them to launch a priority project to improve the Liberator’s performance. Air Materiel Command undertook the ‘B-24 Weight Reduction Program’, with the objectives of improving the speed and altitude capabilities of the aircraft, and also of solving the poor forward visibility and crew quarters problems.

In March 1944, at Wright Field, the Weight Reduction Committee considered a range of options. Among these were more powerful turbo superchargers to improve the ceiling, a faired Bell power boost tail turret, and a single tail assembly calculated to add 10 mph to the B-24’s speed.

The B-17 nose was better streamlined, and provided adequate working space for the navigator and excellent visibility for the bombardier. It was at first used as a bench-mark by which to measure any B-24 modification. The suggestion was made to put a Fortress nose onto a Liberator airframe.

On 25 May 1944, Air Materiel Command assigned the experiment a First Priority Project rating. A preliminary study at Wright Field reported that a completely new nose design would be more practical, but conceded that fitting a B-17 nose was feasible. The actual conversion was scheduled to begin in June, at Air Service Command’s Middletown, Ohio, facilities.

It was agreed that the project should be finished 20 days after receiving a new B-17G nose section from the Douglas plant at Long Beach, California. The airframe was to be B-24J serial 42-73130, made available by Aircraft Test Control and flown to Middletown on 5 June. The aircraft was weighed, and work began on removing the nose and making a mock-up mating structure.

As the project looked for ways to shorten their 20-day time-frame, they found that an accident at Langley Field, Virginia, had considerably damaged B-17G serial 42-97772, but the nose section was still fairly intact. It was requisitioned and reached Middletown on 11 June. The nose section from California arrived five days later and was used to replace damaged parts on the section from Langley.

Now began a complex mating of the two major components. Not only were these of quite different cross sections, but installed equipment did not match up. Side structural fairings were formed by a continuation rearwards of the side components of the B-17 nose section, to end at a point on the B-24 fuselage just forward of the bomb bay doors. The reverse happened on the upper fuselage, where the B-24 was faired forwards onto the B-17 nose.

The modification was completed on 2 July. Whilst not over-attractive, the new nose did at least appear to be an aerodynamic improvement. One problem was that the new nose not only added about two feet to the overall length of the aircraft, but it also increased its weight by 437 lb.

It was sent to Wright Field for a check-out flight on 6 July by the Flight Section of Materiel Command. With a gross takeoff weight of 56,000 lb and after speed, power and stability tests at 10,000 ft the test crew concluded the aircraft performance was ‘…essentially the same as other B-24 airplanes’, but with an airspeed ‘… apparently eight and a half miles an hour faster’. The aircraft was sent to the AAF Proving Ground at Eglin Field, Florida, via Bolling Field, Washington, DC, for the edification of Pentagon representatives.

Three flights were scheduled. The first, at low altitude, was for familiarisation and instrument calibration. The next two flights would be identical except that, on the third, the aircraft would carry the weight of a fully-loaded B-24J.

The missions were flown during August. On both altitude flights, the aircraft was only able to reach a ceiling of 18,500-19,000 ft – about two thirds that of an ordinary B-24. At that point cylinder head temperatures soared and the cowl flaps had to be opened, adding to drag, preventing any further climbing, and producing a mild tail buffeting.

The Eglin report condemned the modified aircraft as ‘operationally unsuitable’. They pointed to weight increase, stability problems, the poor ceiling and generally poor performance, and recommended the project be discontinued.

Finally the Engineering Division of Air Materiel Command admitted that it would be better simply to redesign the B-24J nose. Most of the added weight was due to ammunition for the B-17 nose and cheek guns, almost a third of a ton. This weight did offset the aerodynamics problems of the forward-stretching nose somewhat, which apparently would otherwise have been worse.

There was some dispute that the head temperatures which prevented climbing to a higher ceiling could be blamed on the B-17 nose. They had allegedly been reported in other B-24Js. The test crews agreed that the crew space in the nose had been vastly improved.

XB-24K – An experiment made by Ford by splicing a B-23 Dragon tail empennage onto a B-24D airframe. The aircraft was more stable and had better handling than other models, leading to the decision to incorporate a single tail in the PB4Y-2 and B-24N.

B-24L – Because of the excessively high gross weight of the B-24J, the Army pushed for a lighter version. In the B-24L, the Sperry ball turret was replaced by a floor ring mount with two .50 calibre machine guns, and the A-6B tail turret by an M-6A. Later aircraft were delivered from the factory without tail armament. An A-6B, M-6A, or a manually operated twin .50 calibre mounting was then installed at a depot before arrival at operational units. The L model was built only at Willow Run and Consolidated’s San Diego factory.

B-24M – An enhancement of the B-24L with further weight-saving devices. The B-24M used a lightweight version of the A-6B tail turret; the waist gunner positions were left open. For better visibility from the flight deck, the windshield in Ford-built aircraft was replaced by a version with less framing from Block 20 onward. The B-24M became the last production model of the B-24; a number of those built flew only the course between the factory and the scrapyard.

XB-24N – A redesign of the B-24J, made to accommodate a single tail. It also featured an Emerson 128 ball turret in the nose and a stationary tail gunner’s position. While 5,168 B-24Ns were ordered, the end of the war resulted in cancellation of all contracts before production could begin.

YB-24N – Pre-production service test version of the XB-24N.

XB-24P – A modified B-24D, used by Sperry Gyroscope Company to test airborne fire control systems.

XB-24Q – a General Electric conversion of B-24L-15-FO 44-49916 modified by replacing the standard tail armament with a radar controlled tail turret. This turret was being tested for use on the Boeing B-47 Stratojet.

XB-41 – As there were no fighters capable of escorting bomber formations on deep strike missions early in war, the Army authorized tests for heavily armed bombers to act as escorts. The XB-41 had fourteen .50 calibre machine guns, including a Bendix chin turret and a second Martin A-3 turret on the upper fuselage. A single aircraft was completed in 1942. Performance changed drastically with the addition of more turrets. The escorts were also unable to keep up with bomber formations once the bombs had been dropped. The results of 1943 testing were very negative and the project was cancelled.

AT-22 or TB-24 – C-87 used for flight engineer training.

RB-24L – Developed for training B-29 gunners on an identical remote gun system installed on a B-24L.

TB-24L – As with the RB-24L, but with additional radar equipment.

C-87 Liberator Express – Passenger transports with accommodation for 20 passengers.

C-87A – VIP transports with R-1830-45 instead of – 43 engines and sleeping accommodations for 16 passengers.

C-87B – Projected armed transport variant with nose guns, dorsal turret, and ventral tunnel gun; never produced.

C-87C – USAAF/AF designation for the RY-3.

XC-109/C-109 – Tankers with specialized equipment to help prevent explosions, used to ferry fuel from India to China to support initial B-29 raids against Japan.

XF-7 – Photographic reconnaissance variant developed from the B-24D.

F-7 – Photographic reconnaissance variant developed from the B-24H; -FO block.

F-7A – Photographic reconnaissance variant developed from the B-24J; three cameras in the nose and three in the bomb bay.

F-7B – Photographic reconnaissance variant developed from the B-24J; six cameras in the bomb bay.

BQ-8 – A number of worn-out B-24D and B-24Js were converted as radio-controlled flying bombs to attack German targets.