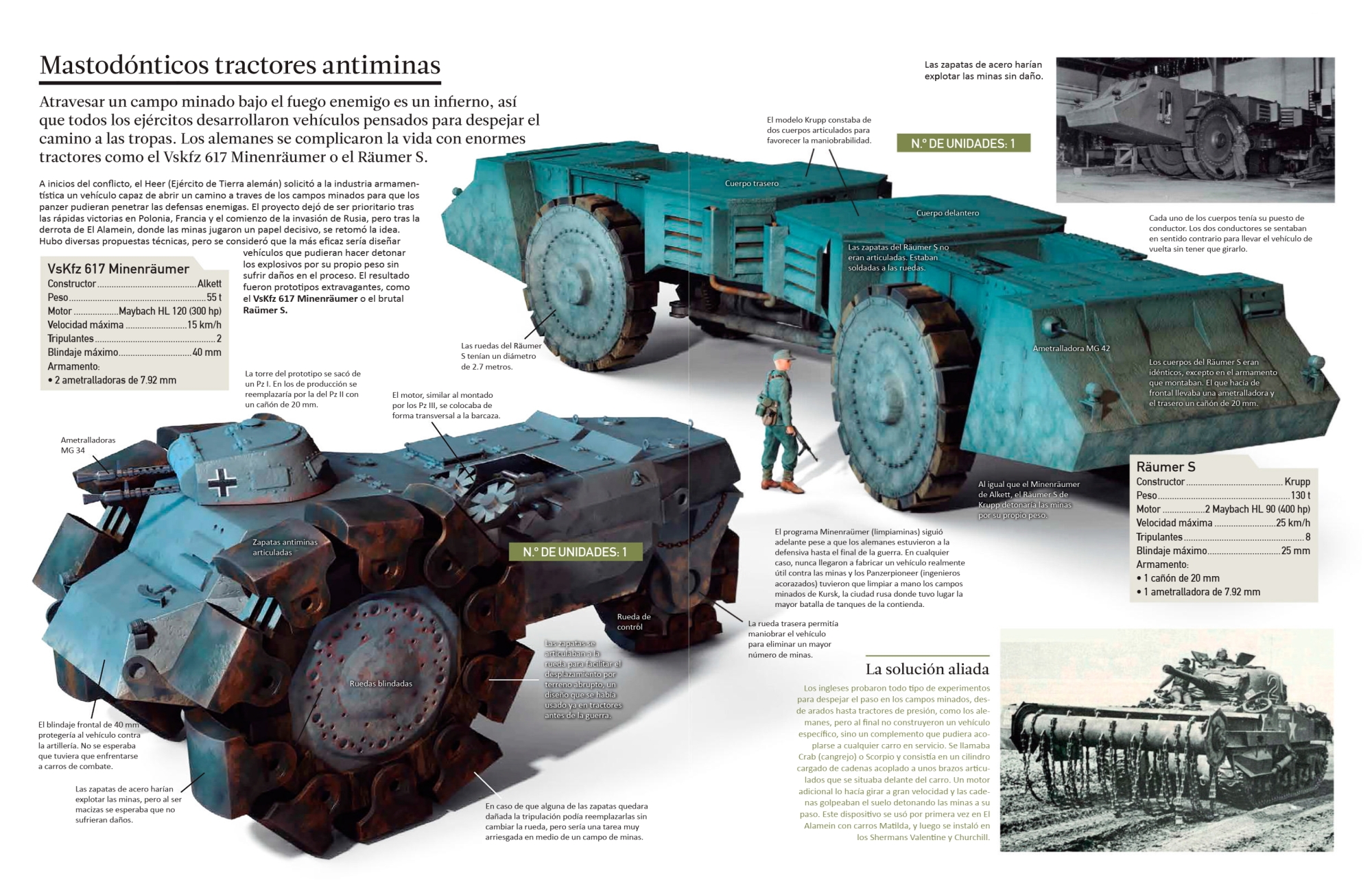

Krupp Räumer S (Selbstrantrieb) Schweres Minenräumfahrzeug

In 1944, Krupp constructed the prototype of a super heavy mines destroyer. This monster of 130 tonnes was articulated in its center, and was suspended on 4 wheels out of steel of 2.7m covered with shoes. Each part of Räumer S was propelled by Maybach HL90. The vehicle was 15 m long and 4 m high. The track widths differed between the front and rear to encourage a wider sweep path.

This odd-looking vehicle was designed by Krupp with the apparent intent of exploding mines with its reinforced wheels. The wheels were heavily constructed to withstand the mine blast, the suspension robust

The Räumer S from Krupp was ordered by the Waffenamt at the same time and to meet the same specifications as the Alkett-Räumgeraet. Krupp was to complete a single experimental model in September 1942 following drawing AKIF 52142 dated 6 July 1942. The “S”, in the name stood for Selbstantrieb (self – propelled). Instead of the three-wheel design created by Alkett, Krupp had created a four-wheel design with each wheel independently driven. Dimensions and weight of the final design (110 metric tons) far exceeded the original specification.

As described in the draft manual dated 1 July 1944: The Räumer is a device that can clear roads and fields of mines without especially endangering the crew. The two heavy sections of the vehicle caused all mines to explode which were set to detonate b pressure. The forces created by the explosions had to be withstood by the high-strength wheels. Because mine detonation will cause the wheels to jump half a meter and then fall into mine holes up to 90 centimeters deep, the vehicle is well sprung, has large-diameter wheels, and the wheels are independently driven To achieve cross-country mobility, the Räumer consists of two articulated halves, fastened together at the steering linkage. The halves can independently tip up to 22 degrees to the right or left (a total of 44 degrees against each other). Two Maybach HL 90 P 20-K engines, each developing a peak of 350 metric horsepower at 4000 rpm, provide the power needed to drive the Räumer S at maximum road speeds of 25 km/hr. Mine clearing is to be done at speeds of 4 to 8 km/hr. The Räumer has two driver stations and can be driven selectively in either direction. Four seats cushioned with springs and hydraulic shock absorbers were located in each driving compartment for the crew of eight, including the two drivers. On 4 June 1943. Wa Pruef 5 was shown the components that had been completed by Krupp including the wheels, frames for the superstructure the steering linkage, and the armor box for the engine and driver compartments. Krupp was to complete partial assembly at Essen in three weeks and then due to bombing raids on Essen, the Räumer was to be transferred to another location to complete the outfitting of the interior On 10 August 1944, Wa Pruef 5 was again shown the partially completed Räumer S, this time at Hillersleben, and ensured by Krupp that it would be completed in September. On 20 October 1944 Krupp reported that the Räumer S hadn’t been completed by 15 September due to unidentified problems. Krupp stated that assembly at Hillersleben should be completed in early November 1944 and trials conducted at Kummersdorf. At the end of the war the Räumer S was found by American troops still at Hillersleben.

The prototype of Räumer S was captured at the end of the war by the U.S. Army.

The Räumer S was captured in Hillersleben 1945. It was divided into two parts and moved to a U.S. Depot near Paris. Then it was lost…

Alkett Minenräumsfahrzeug

This fighting vehicle was created by a joint effort of three German firms: “Krupp”, “Allkett” and “Daimler-Benz”. The label on the turning mechanism has the date – IX/41. Therefore, it is possible to assume that the whole project was assembled no earlier than the end of 1941.

The first mention of this large sized mineroller was found in a Russian paper about “some interesting German experimental samples of arms and vehicles”. This paper was written in the summer 1946. Unfortunately, it has not been established where this machine was discovered. Photos of the vehicle indicate that the mineroller was discovered complete and serviceable.

In 1947, the mineroller was delivered to Kubinka’s Poligon and was subjected to survey, measurement, weighing and movement tests. But the tests for actual minesweeping of mine fields were not carried out at that time because some mechanisms of the vehicle worked unreliably during the tests.

In the test report it is written: “from a design stand point the mineroller is not modern and does not represent any interest”. In another document about this mineroller it was written: “large weight, low specific power, the small speed of the vehicle and weak support of the machine of this large sizes makes it easily destroyed with artillery fire”. Upon termination of tests the mineroller (or “räumenpanzer”) has occupied a place in the Kubinka’s Poligon collection, and lately has been seen in our tour of the Kubinka’s Museum.

The design of this mineroller is unusual. Its appearance reminds one of a strongly reinforced German heavy gun carriage on which instead of a gun-barrel has been mounted an armoured cabin containing the engine and fighting turret. Similarly to other monster, but on four wheels and known under the name “Räumer – S”, Kubinka’s exhibit represents the special preserved machine, intended only for minesweeping of mine fields.

The body of this mineroller has four sections: driving, fighting, transmission and engine compartments. In the driver’s area (in the forward part of the body of the machine) are placed the controls and instrument panels. The fighting compartment is placed in the central part of the body was topped by a rotating turret from the PzKpfw I tank. The turret, armed with two co-axial MG 34 machine guns, was intended for defence of the machine from an enemy’s infantry. On our examined sample one machine gun was absent. The transmission section was placed under the fighting compartment and on either side of it. The transmission containes mechanisms to transfer the torque from the engine to turning the wheels, accumulators and part of the drive mechanism. The engine compartment, located in the rear of the body, contains the engine with power supply systems and cooling system, the main friction clutch and part of the drive mechanism.

The body is constructed of welding rolled armoured sheets of low hardness, from 20 up to 40 mm thick. The bottom of the body has a special design to counteract an explosive wave. The bottom is made of double thickness armor and is amplified (strengthened) by cross bracing. All mechanisms of the power unit installation and the transmissions are mounted on demountable internal supports of 20 mm thickness. In a forward part of the hull, on its roof, is installed and bolted on a superstructure made by welding armoured sheets of 10-35 mm thickness. On the roof of the superstructure a turret of the PzKpfw I tank is mounted.

The transfer of the drive torque from the engine to the drive sprokets is made by the following connections: the engine, main friction clutch, drive shaft, gearbox, main and intermediate transfer cases, final drive gear, and drive sprocket.

Turning the machine required turning a small steering wheel, located in the rear part of the body. Control of the turn is mechanical with the selection of drive shafts from the power drive. The drive controls included a steering wheel, system of propeller shafts, reducer of selection of power, worm-gears and chains.

The driver of the machine turned a steering wheel and through the propelled shaft, applied the appropriate friction clutch of a reducer to select the gear. After the worm-gear began to rotate chains were pulled by the steering wheel to the right or left as typical.

To slow the mineroller were brakes, mounted on an outside surface spinning wheel. The brake shoes of 75mm width had a covering of “Ferrodo”. The control of the brakes came directly from lever steering controls and emergency braking pedals.

The main peculiarity of this mineroller is the use of special caterpillar tracks with shoe pads attached to the driving wheels. Structurally they were similar to block pads used on the wheels of German heavy field guns of the First World war. However, the durability of these pads was much amplified (strengthened). Past experiments have shown that explosions from antitank mines under a loaded vehicle with these pads only produces minor damage to the connecting links.