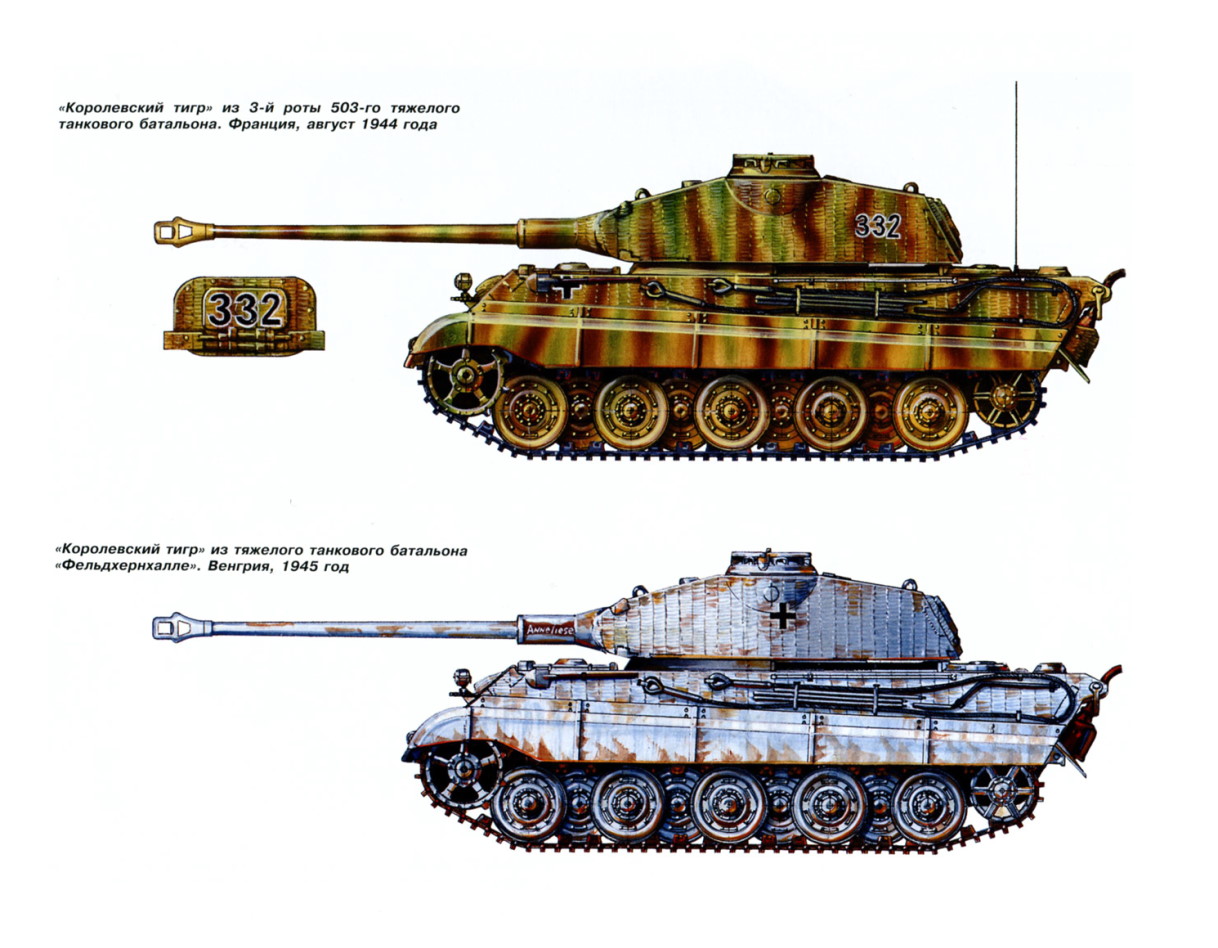

Bottom “Porche-design-Krupp-built” Tiger II is Anneliese

Probably the best-armed and protected tank to take the field in World War II, the Tiger II suffered from low production numbers, a relatively weak power train, and German tactical decisions that worked to the benefit of the Allies.

Designed by Henschel, the Tiger II was originally fitted with a turret of Krupp’s design. Three prototypes and the initial forty-seven production vehicles had turrets that were originally intended for Porsche’s ill-fated Typ 180. On orders from the German Führer himself, Tiger II armament was based on the 88 mm FlaK 41, which now had the form of the 8.8 cm L/71 KwK 43.

Though the original intent was for the Tiger II to be based on the Tiger I, in the event the Tiger II relied for much of its design and components as well on the stillborn MAN Panther II project. As things finally played out, the only Tiger II component taken over from the Tiger I was the transmission, and even this was slightly modified.

Ultimately, although the Tiger II entered production in January 1944 and remained in production through March 1945, only 474 of the vehicles were constructed.

Even though the number of Tiger II vehicles was relatively low, those that were produced exhibited several variations. As noted above, the first 50 Tiger II tanks incorporated Krupp turrets originally intended for the Porsche heavy tank project and therefore called “Porsche” turrets. Krupp turrets designed specifically for the Henschel Tiger B were used on the remaining Tiger II vehicles.

A few of the earliest Tiger II vehicles featured a telescoping snorkel for fording, but this was soon discontinued. In April 1944, changes were made near the two shackles on the front and rear hull extensions so as to allow the use of “C” hooks. Other changes occurring at about the same time included the addition of a four-segment turret ring guard and a notch that was added to the glacis in the area of the radio operator’s periscope. At the same time, the screens on the rear deck of the tank had to be modified to accommodate the new ring guard. Meanwhile the left hole in the turret face was plugged so that the binocular TZF 9b/1 gunner’s sight could be replaced with the monocular TZF 9d sight.

Most of the tanks constructed after April 1944 incorporated a two-piece stepped gun barrel, in place of the earlier single-piece tapered tube.

In May 1944, the very flexible original track design, which featured small bar links, was replaced with a new track that had a solid-bar connecting link and was more rigid. This feature exacerbated rolling resistance, but decreased the likelihood of a track working its way off the sprocket. The change to the new track necessitated a switch to a new drive sprocket that had only nine teeth, instead of the eighteen on the sprocket used with the earlier track. Meanwhile, a vane sight was incorporated in the roof of the turret for the commander to use.

June 1944 saw major changes in Tiger II manufacture. In order to mount a jib boom crane with a 2-ton lifting capacity, three sockets were added to the tank’s turret roof. A shorter muzzle brake was incorporated at about the same time. But the biggest change that June was the new turret that was introduced. This turret, known as the “production turret” or “series turret,” was very different from its predecessor. The Porsche turret had featured a rounded face and a left-side bulge to accommodate the cupola. In the new series, the turret’s face was flat and the turret’s side armor was less steeply sloped, a design that obviated the need for the bulged side.

The commander’s cupola began to be bolted, rather than welded, onto the turret, beginning in August 1944. The weld seam, a prominent feature on earlier models, obviously is absent from the tanks with the cupola bolted in place. That same month, Tiger II tanks started to roll off the assembly line wearing a three-color factory camouflage scheme.

Already in September, however, that three-color scheme was abandoned and the new Tigers were left in their red oxide primer to which patches of dark yellow, reddish brown, and olive green were added. That same month the Zimmerit antimagnetic mine coating was dispensed with.

In October 1944, the 20-ton jack and the corresponding mounting brackets were discontinued.

Things remained largely the same, then, for nearly three months—apart from changes in the design of the latches on the hull personnel hatches and the intermittent use of a rain shield over the gunner’s sight aperture.

Then in January 1945, Henschel’s assembly plant began to receive the armor components prepainted in RAL 6003 olive green. After assembly, RAL 8017 red brown and RAL 7028 were sprayed on to the vehicles in a hard-edge camouflage scheme.

Finally, in March 1945, came the final major change: another change of the track. In place of the earlier double-link track, the track introduced in March 1945 was a single-link version. Once again the drive sprocket needed to have eighteen teeth. Only a few vehicles were actually produced with this track, since it was in March 1945 that US troops seized control of Henschel’s Kassel factory, the Tigers’ home.

The Tiger II’s long main armament, the epitome of the family of 88mm antiaircraft/antitank guns that had terrorized enemy armor since the Spanish Civil War (1936-39), fired high-velocity rounds along a relatively flat trajectory. In combination with an excellent gunsight, the weapon system was accurate at long range, which enabled rapid targeting and a high first look/first hit/first kill probability. However, the lengthy barrel’s overhang stressed the turret ring, and made traverse difficult when not on level ground. Optimally initiating combat at distances beyond which an enemy’s main armament could effectively respond, the Tiger II’s lethality was further enhanced by its considerable armor protection, especially across the frontal arc that provided for a high degree of combat survivability. Although the vehicle’s glacis does not appear to have ever been penetrated during battle, its flanks and rear were vulnerable to enemy antitank weapons at normal ranges.

In the hands of an experienced crew, and under environmental and terrain conditions that promoted long-range combat, the weapon system achieved a high kill ratio against its Allied and Red Army counterparts. 503rd Heavy SS Panzer Battalion, for example, was estimated to have scored an estimated 500 “kills” during the unit’s operational life from January to April 1945. While such a figure was certainly inflated as accurate record keeping was hindered by the unit’s dispersed application and chaotic late-war fighting where the Soviets eventually occupied a battlefield, it illustrated the success of the weapon system if properly employed and supported. Of 503rd Heavy SS Panzer Battalion’s original complement of 39 Tiger IIs only ten were destroyed through combat, with the remainder being abandoned or destroyed by their crews due to mechanical breakdowns or lack of fuel. As 503rd Heavy SS Panzer Battalion never received replacement tanks like its brethren in 501st and 502nd Heavy SS Panzer Battalions (which were given 2.38 and 1.7 times their respective 45-vehicle TO&E allotments), its Tiger II combat losses averaged less than 50 percent.

Because of the chaotic combat environment throughout Pomerania, and the need to quickly allocate resources to several threatened sectors at once, the Tiger IIs were frequently employed singly, or in small groups, often at the will of a local senior commander. In much the same way as with the French in 1940, 503rd Heavy SS Panzer Battalion’s armor acted more in an infantry-support capacity than as a unified armored fist. The Tiger IIs would perhaps have been better used organizationally to fill a Panzer regiment’s heavy company by strengthening existing, depleted parent formations; but instead they remained in semi-independent heavy Panzer battalions until the end of the war. Forced to rely on small-unit tactics, Tiger II crews played to their strengths by adopting ambush tactics to minimize vehicular movement and pre-combat detection, especially from enemy ground-attack aircraft.

As tankers regularly spent long hours in their mounts the Tiger II’s relatively spacious interior helped reduce fatigue, and made operating and fighting within the vehicle somewhat less taxing. A good heating and ventilation system improved operating conditions, which then reduced crew mistakes that were all too common during a chaotic firefight. Although the Tiger II had well-positioned ammunition racks that facilitated loading, projectiles that were stored in the turret bustle were susceptible to potentially catastrophic damage caused by spalling or projectile impacts. Even after Henschel incorporated spall liners to reduce such debris, concerned crews would often leave the turret rear empty, which correspondingly made room to use the rear hatch as an emergency exit.

The cost to produce the Tiger II in manpower and time (double that of a 45-tonne Panther), and its high fuel consumption, brought into question why such a design progressed beyond the drawing board considering Germany’s dwindling resources and military fortunes. It was partly a response to the perpetual escalation of the requirement to achieve or maintain battlefield supremacy, and much of the blame rested with Hitler and his desire for large armored vehicles that in his view presumably reflected Germany’s might and reinforced propaganda. By not focusing resources on creating greater numbers of the latest proven designs such as the Panther G, German authorities showed a lack of unified direction and squandered an ability to fight a war of attrition until it was too late to significantly affect the outcome. Limited numbers of qualitatively superior Tiger IIs could simply not stem the flood of enemy armor.

Jagdtiger SdKfz 186

Faced with increasing numbers of increasingly capable Allied vehicles, Germany sought to develop a tank destroyer that was so heavily armed and armored it could absolutely dominate the battlefield.

That armament was 12.8 cm PaK 44 L/55, inspired by the Soviet 122 mm gun. The Germans opted for the slightly larger gun in part to utilize some of the tooling previously created to produce 12.8 cm naval weapons.

While some of these formidable weapons were mounted on towed artillery carriages, two types of mechanized mounts were proposed. One was the German superheavy tank Maus. The other was the largest tank destroyer to enter series production, the Jagdtiger. It was hoped that not only would this vehicle be effective against enemy tanks, including those beyond the effective range of other guns, but also would be decisive against fortifications.

In order to mechanize the weapon, first a mock-up based on the Panther chassis was created. This style was discarded, and in October 1943 a second mock-up based on the Tiger II chassis, albeit lengthened forty centimeters, was shown to Hitler.

Two trial vehicles were assembled: chassis number 305001 utilized an eight-roadwheel Porsche torsion-bar suspension system, while chassis number 305002 used the Henschel nine overlapping wheel suspension system like that used on the production of Tiger II.

Both were assembled by Nibelungenwerk in February 1944. In total, 150 of the vehicles, dubbed Jagdtigers, were ordered. Ten more of these vehicles were built with the Porsche-designed suspension, while the balance of the seventy to eighty-eight vehicles actually produced featured the Henschel suspension.

Only two units were issued the massive vehicles, the heaviest armored vehicles to see series production during the war, schwere Panzerjäger-Abteilung 653 and the schwere Panzerjäger-Abteilung 512. Their considerable weight, compounded by the vehicles often being crewed by young, inexperienced men, led to the Jagdtiger being of limited usefulness.

Dr. Professor Ferdinand Porsche suggested a paired external torsion bar suspension with single roadwheels, as opposed to the individual internal torsion bars with double roadwheels on the Henschel version. The roadwheels themselves were 800mm in diameter on Henschels Jagdtiger, and 700mm on Porsches.

The Porsche Jagdtiger was 1.2 tons lighter than the Henchel one, demanded 450 less working hours and was much cheaper. It was also possible to remove one 2-wheel section, without touching the other wheels – something that was impossible with Henchels overlapping wheels. On the other hand, the weight on a single roadwheel was about 200kg on Henschels Jagdtiger, and the Porsche one over 4600kg! Furthermore, there were 1/8 part more wear and tear on the Porsche roadwheels per centimetre than on the Henschel ones.