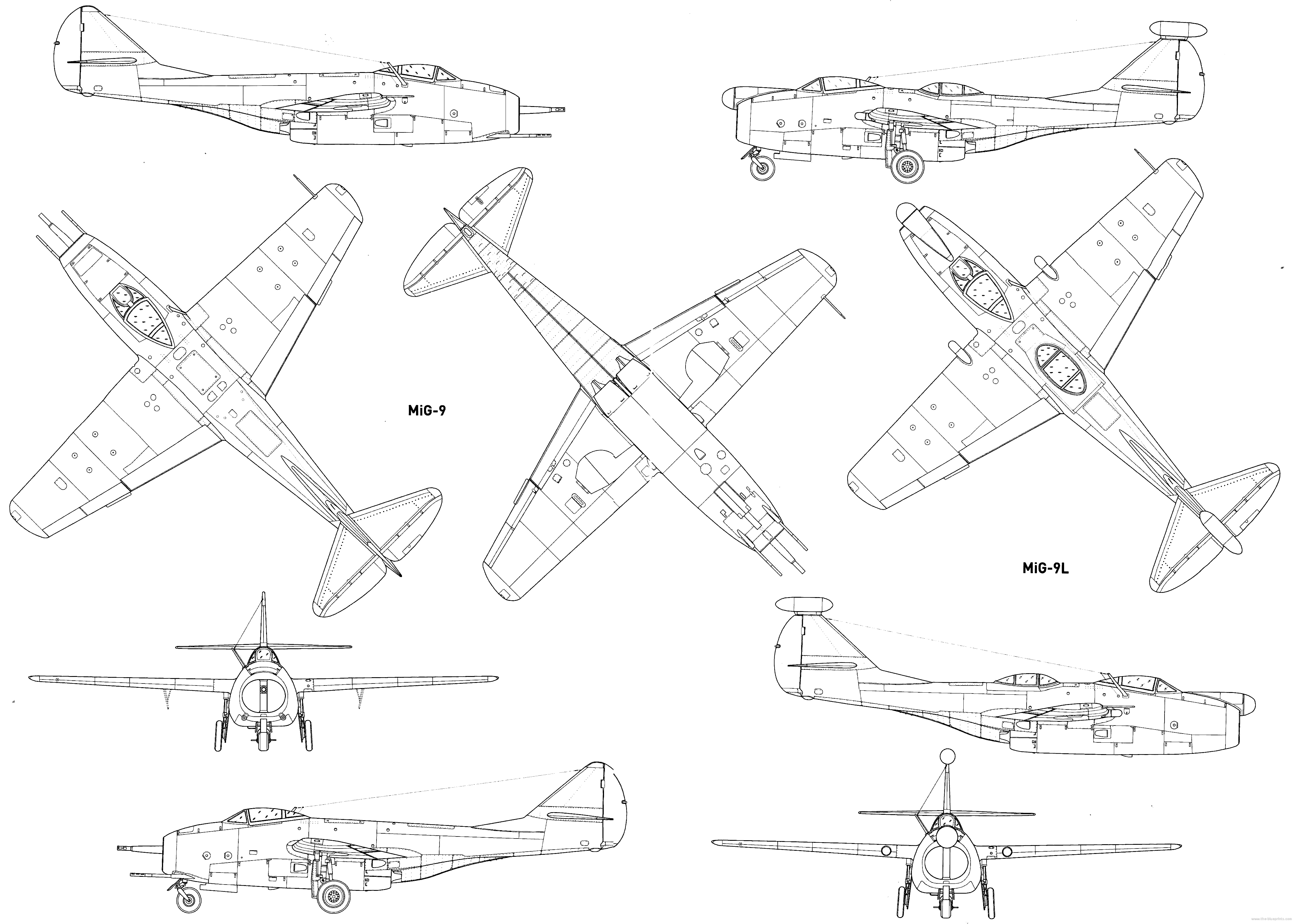

The MiG-9 was a cantilever mid-wing monoplane of all-metal

construction with a smooth stressed skin and a retractable tricycle undercarriage.

To simplify the process of assembly the aircraft was divided into several

production units.

Fuselage:

semi-monocoque stressed-skin structure. Duralumin was used as the main

structural material.

Technologically the fuselage was built in two sections – the

forward fuselage (frames Nos. 1 through 15a) and the rear fuselage (frames Nos.

15 through 35), which were joined together by fittings. The fuselage structure

incorporated two air ducts supplying air to the engines. The ducts had an

elliptic cross-section changing to circular at the rear and ran along the

fuselage sides, flanking the cockpit.

The forward fuselage housed the armament, the nose landing

gear unit, the cockpit with the canopy, controls and appropriate equipment, a

fuel tank and other units. The forward fuselage framework consisted of four

variable-section longerons, 15 frames, a number of stringers, two beams for the

installation of the nose gear unit and two beams for the attachment of the

armament. Attached to frame No. 1 was the front fairing which formed the

aircraft’s nose with a bifurcated air intake for the powerplant. The inlet

ducts were structurally joined to the beams of the nose gear unit and to the

armament attachment beams. Together with the floor of the cockpit, the skinning

and the longitudinal structural members they formed a structure sustaining all

the stresses of the forward fuselage.

The framework of the rear fuselage consisted of four

longerons, 20 frames, a number of stringers and two ribs to which the main

undercarriage units were attached. The aft fuselage housed equipment, wiring

and control units, as well as two bag-type fuel tanks in containers. A heat

shield protecting the fuselage undersurface from hot exhaust gases was mounted

between frames Nos. 19 and 34. Between frames Nos. 19 and 29 the fuselage was

structurally integral with the lower part of the fin. Lugs for mounting the

stabilizers and the fin were installed on frames Nos. 32, 34 and 35.

The landing gear attachment ribs together with the wing

attachment beam and engine attachment beam formed a load-bearing structure

absorbing the loads from the undercarriage, the wings and the engines.

The cockpit was placed in the forward fuselage over the

engines within the space between frame No. 5 and the sloping frame No. 11 a.

The cockpit canopy had a streamlined shape, consisting of a fixed windshield

and an aft-sliding rear portion which could be jettisoned in an emergency. Aft

of frame No. 5 the cockpit floor was partly formed by the inlet ducts. The rear

part of the floor adjoining the rear wall of the cockpit sloped in such a way

that the pilot’s seat was placed between the engines. The seat was a duralumin

pan of the usual type, designed to accommodate a parachute and attached to the

cockpit floor by brackets. The seat was provided with a harness comprising leg

belts and shoulder straps. A padded seat back was attached to the rear cockpit

wall. A padded headrest was attached to the rear bow of the sliding part of the

canopy. The cockpit armour comprised two steel armour plates 12 mm (0.47 in.)

thick and, on some machines, a 55-mm (2.16-in.) bulletproof glass plate mounted

in the front part of the windshield. An attachment unit for the

centrally-mounted cannon was installed in the cockpit on suitably stressed

elements of the structure; the cockpit also housed the control stick and rudder

pedals.

Wings: unswept

wings of trapezoidal planform and all-metal two-spar riveted construction,

built as one-piece panels attached to the fuselage sides. Incidence 1°,

dihedral 2.5° and thickness-to-chord ratio 9% over the entire span.

The wings employed a combination of airfoil sections. A

low-lift TsAGI1-A-1 0 airfoil was used in the span segment between ribs Nos. 1

and 3; a high-lift TsAGI1-V-1 0 airfoil was used between rib No. 6 and the

wingtip, and the span segment in between featured a transitional airfoil

section. This combination of airfoil sections precluded the possibility of the

aircraft entering a spin at high angles of attack.

The wing framework comprised two spars, 21 ribs and a number

of stringers. The wings were equipped with Frise ailerons and TsAGI-type

slotted flap§. (modified Fowler flaps). The flaps occupied the portion of the

trailing edge between ribs Nos. 1 and 11, the ailerons being accommodated

between ribs Nos. 11 and No. 21. The ailerons’ maximum deflection angle was

+22S/-14S. The flaps were set at 20° for take-off and 50° for landing. The

trailing-edge section of the wings between ribs Nos. 1 and 6 had a cutout for

the wheel wells. The wings also housed six bag-type fuel tanks which were

placed in containers.

Tail unit: the

empennage was of all-metal construction, featuring high-set cantilever

stabilisers. The tail surfaces employed a NACA0009 symmetric airfoil section.

The fin and the stabilisers were detachable. The horizontal tail was built in

two symmetrical halves, each half having two spars and 11 ribs. The front

stabiliser attachment fittings were of a rack type, permitting the incidence of

the stabilisers to be adjusted on the ground between the angles of +1°10′ and

-4°. The starboard elevator incorporated a steerable trim tab.

The fin structure was similar to that of the stabilisers.

The fin’s frame comprised two spars and six ribs. The elevators were of

allmetal construction and were attached to the stabilisers by five brackets.

The all-metal rudder was attached by three brackets to the fin and the

fuselage.

Landing gear:

pneumatically retractable tricycle type, with single wheel on each unit. The

wheel base was 3.02 m (9 ft 11 in.). All three units had levered suspension and

oleopneumatic shock absorbers, those on the main undercarriage struts being

mounted externally. The main units retracted outwards into the wings, the nose

unit aft into the fuselage. The levered-suspension main units had 660 x 160 mm

(25.74 x 6.24 in) wheels equipped with brakes and mounted on semiforks. The nose

unit had a non-braking wheel measuring 480 x 200 mm (18.72 x 7.8 in); it

featured an attachment point, an integral shock absorber, a shimmy damper, an

uplock, a downlock and a retraction jack. Each mainwheel well was closed by two

doors, the bigger one being attached to the main gear strut and the smaller one

to the wing; the nosewheel well had a forward door segment hinged to the nose

gear oleo and two lateral doors at the rear.

Powerplant: two

RD-20 Series A2 single-shaft axial-flow turbojets delivering 800 kgp (1,764 Ib

st) each. The engine had a seven-stage compressor, a single-stage turbine with

air-cooled blades and a variable nozzle with a movable centre-body. Each engine

had its own Riedel two-cylinder two-stroke starter.

The fuel (kerosene) was accommodated in ten tanks. Four

tanks (including three bagtype tanks) were housed in the aft fuselage, the

remaining six were located in the wings. The total capacity of the fuel system

was 1,595 litres (351 Imp gal), of which 1,225 litres (269.5 Imp gal) could be

carried in the four fuselage tanks. To facilitate engine start-up a special

start-up fuel system using more easily combustible petrol was provided.

Armament:

production MiG-9s were equipped with one centrally-mounted 37-mm (1.45 calibre)

Nudel’man N-37 cannon with 40 rounds and two 23-mm (.90 calibre) Nudel’man/

Sooranov NS-23K cannons with 80 rpg. The N-37 weighed 103 kg (227 Ib) and

possessed a rate of fire of 400 rounds per minute, the muzzle velocity of the

shell being 700 m/sec (2,296 ft/sec). The NS-23K cannon had a rate of fire of

600 rounds per minute and a muzzle velocity of 680 m/sec (2,230 ft/sec). The

N-37 protruded 1.16 m (3 ft 9.67 in.) beyond the plane of the air intake lip,

while the NS-23K cannons protruded 0.5 m (1 ft 7.68 in.). The ammunition boxes

were accommodated in an equipment bay between fuselage frames Nos. 1 and 6.

It should be noted that some production aircraft were

provided with attachment points for a centrally-mounted cannon of a larger

calibre. Thus, the first three machines of the ‘parade’ batch (c/ns 106001

through 106003) were provided with attachment points, ammunition box and link

and case chutes for the 57-mm (2.24 calibre) Nudel’man N-57 (izdeliye 120P)

cannon. MiG-9s with c/ns 106004 through 112001 were fitted only with attachment

points for the N-57 cannon (they differed in having an increased-diameter

internal bore).

Avionics and

equipment: The basic range of equipment installed on production MiG-9s

comprised the following items: an RSI-6 CRei-VM’) short-wave transceiver; an

RPKO-10M direction finder, a single 1.5-kilowatt GSK-1500 DC generator driven

by one of the engines, a 12-A-10 DC battery and an RU-45A AC converter. The

cockpit housed flight and navigation instruments and engine control

instruments: a US-1 000 airspeed indicator, a VD-12 altimeter, an electrical

gyro horizon combined with a Horn-type turn indicator; a PDK-44 compass, a

VR-30 vertical speed indicator, a TF-15 tachometer, an MP-80 kerosene pressure

gauge, an EDMU-1 gas pressure gauge, a TVG-44 exhaust gas thermometer, a BE-296

fuel gauge and TME-45 engine oil thermometers.

A single-wire aerial was attached with one end to a strut

which was mounted on a fuselage frame, offset to starboard; the other end of

the aerial was attached to the fin.

The aircraft was fitted with a PKI-1 reflector gunsight

which was later replaced by an ASP-1 N optical sight; some machines were

provided with an S-13 gun camera in the wing/fuselage fairing.

Oxygen system: a

KP-14 breathing apparatus which ensured oxygen supply for the pilot to an

altitude of up to 12 kilometres (39,370 ft).

Control system:

conventional mechanical control system comprising control stick, rudder pedals

and trim tabs. The stick was connected to the ailerons and elevators by

push-pull rods and bellcranks, while the rudder was controlled by means of

steel cables. The elevator trim tab installed on the starboard elevator was

controlled electrically.