In the USA, as in Britain, the origins of the gas turbine engine were much more complicated than has generally been appreciated. Nevertheless, also as in Britain, the Whittle engine played a crucial role in stimulating development.

While still a student at the University of California in 1895, the engineer Sanford Moss had conceived a gas turbine, intended as a stationary unit for industry, commenting later wryly that ‘like most of the other inventors, [I] … at first thought [I] was alone in the gas turbine field’. Moss developed the gas turbine to the hardware stage at General Electric (GE) in Lynn, Massachusetts, in 1904, but concluded that ‘as the power for compression was more than the turbine power … the experiment was a flat failure’. However, Moss went on to become a central figure in the development of the turbo-supercharger for piston aero engines by GE at Lynn. This work, intriguingly, became an important link in the transfer of Whittle’s ideas to the USA.

During the 1930s various turbine schemes were considered in America. Most notable were those at Northrop for a complex turboprop (the Turbodyne) and Lockheed’s interesting jet project, the L-1000, conceived by Nathan C. Price, formerly a steam turbine engineer, who had worked for a while with the Doble steam car concern, which was aiming at a 600 mph aircraft flying at 50,000 feet. However, none of these ambitious schemes could be funded by the inventors or manufacturers, and the US army and navy were not tempted, before the war, to back a new type of engine and underwrite the research and development. The decision in Britain to back the powerful but thirsty Whittle jet was propelled in part by Britain’s vulnerability to air attack from Europe and the short warning time of the approach of hostile bombers. This was not a strategic concern in the USA at the time. It was the impending entry of the USA into the war, and the discovery that active, well-advanced jet work was going on in Britain and in Germany, which acted as the spur.

The actual circumstances in which service and industrial people in the USA became aware of the British work are still somewhat mysterious. For example, it has often been suggested that when General Henry ‘Hap’ Arnold, as head of the US Army Air Corps (USAAC),4 visited Britain in the spring of 1941, he was told about the Whittle engine by officials and, it is said, ‘was astonished when, by chance’, he learned that British jet engines were in an advanced state of development and were ‘about to be flown’. It has also been suggested that he witnessed taxi trials of the E.28/39, and, on his return, asked for a competent US engineer to be sent over to study the Whittle engine. However, the coming of Lend-Lease, and the supply to Britain of turbosupercharged American aircraft for use by the RAF, had already brought USAAC and GE staff over to Britain for engineering support before Arnold’s visit, and the choice of an American engineer to investigate the jet fell, it is said, on ‘the ideal man’, GE engineer D. Roy Shoults, then in Britain as GE’s technical service representative for the turbosupercharger.

Alternatively, according to Schlaifer’s generally authoritative account, D. Roy Shoults ‘picked up from various sources enough information to conclude that turbojet engines were being developed’ before Arnold’s visit and passed this knowledge to Colonel A.J. Lyon, technical representative of the USAAC in Britain. Shortly after this, the MAP showed these two the whole British turbojet programme. According to this version, this information ‘gathered on the ground’ in the UK was then passed back to senior figures in the USAAC and to Arnold, prompting his interest and enquiries in Britain.

In spite of the attention given to Arnold’s contact with the Whittle work, it should be noted that he had, apparently, already been spurred by generic intelligence reports of jet and rocket work in Germany and, before his visit to Britain, had asked the Chairman of the National Advisory Committee for Aeronautics (NACA), Vannevar Bush, to set up a ‘Special Committee on Jet Propulsion’ in February 1941. This was placed under the direction of retired former NACA Chairman William Durand, who proved ‘an exceptionally energetic chairman’. By July 1941, the committee was sponsoring three projects: a pure jet engine from Westinghouse, a ducted fan/jet from Allis-Chalmers, and a turboprop, the TG-100, from the GE plant at Schenectady. All these projects used axial flow compressors, probably because intelligence now was indicating that this was the German approach. The projects were also independent of Whittle’s work at Power Jets and in fact some teams, such as that at Westinghouse, appear to have been later deliberately kept in ignorance of it in order to foster more than one line of development.

However, there is another twist to this story which Edward W. Constant has drawn out, and it is surprising that its implications have not been generally appreciated. This is that, through their industrial links, GE were well aware of work on the Whittle jet that was going on at the British Thomson-Houston factory in Rugby, England, well before ‘Hap’ Arnold or indeed Roy Shoults were made aware of the work at Power Jets. The links between GE and BTH, as manufacturers of steam turbine generating sets, were close; in fact British Thomson-Houston had been formed in 1894 to exploit the patents of the American Thomson-Houston company (an antecedent of GE). By this stage BTH were becoming quite possessive about the test engine they were building for Whittle (describing it in literature as the British Thomson-Houston turbojet engine) and they showed it off to visiting GE engineers in 1939.

As a result of the information they passed to him on their return, Sanford Moss wrote in September 1939 to fellow engineer Dale Streid at GE’s Schenectady plant that:

Mr A.R. Smith has just returned from England and he and his assistant … saw an exhaust gas turbine at the BTH factory for airplane service … . We have the idea that the apparatus involved a centrifugal compressor with ramming intake driven by a gas turbine wheel which furnishes a jet for jet propulsion … .

This was a perfect description of the Whittle jet, although Moss also speculated as to whether part of the combustion gas bypassed the turbine to produce the jet directly. Moss suggested, ‘we have in mind going to Wright Field [the test establishment for the USAAC] with a similar proposition and want to know all we can about the British outfit before we start … [We] would like to present some sort of proposition to Wright Field now.’

It appears that no proposal was actually put to air force staff but, perhaps as a result, GE’s Dale Streid shortly afterwards did a theoretical study on the possibility of jet propulsion for the then very high speed of 450 mph. Another intriguing point raised by Constant is that earlier, the Lynn group frequently tested turbochargers by inserting a combustion chamber between the compressor and turbine and so had been ‘inadvertently running a turbojet’. He notes that in spite of Moss’s continuing sense that the gas turbine was still premature, based on his own earlier disappointments, ‘some of the younger engineers wanted to build a true turbojet’.

The GE advanced engineering staff were in frequent and close contact with air force technical staff from Wright Field over the development and operation of turbochargers, and the clear implication of these ideas and contacts, even though no turbojet programme at first resulted, must be that both GE and the US Air Force were increasingly aware that a gas turbine jet engine would soon be feasible. This reading of events also suggests that when both GE and US Air Force personnel reached Britain during the Second World War, they already knew much more about work on the Whittle idea, and the general feasibility of the jet engine, than has generally been admitted. The confusion about the sequence of events perhaps results from this and a certain coyness, in American circles, to admit how much was known about the secret work of an ally.

In spite of the various gas turbine leads in the USA which have been discussed, knowledge of the Whittle programme suggested that the quickest way into turbojet development was to build on the British experience. Arnold asked for the creation of a working group to facilitate transfer of the British knowledge to the USA in the mutual wartime interest of both sides. The British representation was at a high level, including Air Marshal Linnell at the Ministry of Aircraft Production and Harold Roxbee Cox who was directing the work at Power Jets for the MAP. General Arnold, it is said, selected GE to receive this knowledge, partly because the established aero engine firms of Pratt & Whitney and Curtiss-Wright were fully committed to producing existing types of piston engine but crucially because of its experience with the turbosupercharger. A turbosupercharger (today usually called a turbocharger) consists of a turbine, driven by the exhaust of a conventional piston engine, coupled to a centrifugal compressor which is used to pressurise the inlet air for the piston engine. Ideally, this arrangement exploits and recovers ‘waste’ energy in the piston engine exhaust, to maintain altitude performance to the piston engine which loses power as it ascends into thinner air.

The turbosupercharger had become very much a GE speciality, and so pre-war aero engine development in the US differed from Britain, where mechanically driven superchargers were standard. Turbosupercharger experiments had been tried at the RAE in the 1920s but had not been followed through. This was, in part, because finding alloys for the red-hot exhaust turbine blades seemed an awesome task, although in the USA it had been tackled using new alloys with high nickel, chromium and molybdenum content such as ‘Stellite’ primarily developed for piston engine exhaust valves.

On 1 October 1941, a B.24 Liberator bomber crossed the Atlantic bringing to the GE plant at Lynn a set of drawings for the Power Jets W.2B engine, which the Rover company was then endeavouring to build, as well as an actual engine, the W.1X test unit. This was effectively a duplicate of the W.1 engine, used for the first flight of the Gloster E.28/39, built with a spare rotor for the W.1 and non-airworthy parts which had been rejected for the W.1. Nevertheless, it had proved invaluable for ground test work. (It still survives and today can be seen in the Jet Aviation gallery at the National Air and Space Museum, Washington.)

It should be noted that the transfer of Power Jets design and experience to the USA was not simply a question of shipping over drawings and hardware. Given the importance of the Whittle jet to Britain, it made a substantial commitment of key personnel to the transfer of special knowledge to the USA. With the engine and drawings came three engineers to work with the GE team at Lynn: D.N. Walker, one of the Power Jets senior engineers, G.B. Bozzoni, a highly skilled engine fitter and builder there, and Flight Sergeant J.A. King, who had been seconded to Power Jets from the RAF.

Walker returned to Power Jets after two months. However, Bozzoni and King spent five months at Lynn, returning in March 1942. Whittle himself also went out to the USA in June 1942 for almost two and a half months with frequent contacts with the GE team. Coming after Whittle’s nervous troubles and breakdown, the trip to the USA seems, on the whole, to have been a welcome break for him, and he wrote back to the UK that ‘I get on very well indeed with the engineers over here, because they have both enthusiasm and ability, which is a pleasant change from some we know of.’ However, he began again to experience feelings of exhaustion and strain and was induced to relax for a while in California, recalling that, at one Beverly Hills party, he was induced to ‘relax’ so well that, at 3 a.m., he dived into the pool to join other revellers and ruined his wristwatch. Whittle’s contribution to the GE work seems to have been sincerely appreciated, and on his return Air Marshal Hill, the senior officer representing the RAF in America, wrote to Air Marshal Linnell, ‘Whittle’s visit has been of major significance in promoting closer understanding … . It has made a direct contribution in accelerating diagnosis of the causes of a number of teething troubles experienced by the G.E.C. … . He has won great respect from American engineers … .’

At GE, the development of the Whittle engine was run by Donald F. ‘Truly’ Warner, a ‘top engineer from the turbo-supercharger department’, with the first US-built version, the Type I, being equivalent to the Power Jets W.2B. However, GE had re-drawn the designs to suit American machine shop practice, strengthened the impeller blades, and added an automatic control system. The GE engine also used a superior, US-sourced alloy for the turbine blades from the Haynes Stellite Company and first ran on 18 April 1942, approximately six months from receipt of the drawings. At the same time, the Bell Aircraft Corporation was commissioned to produce the Bell XP-59A – a twin-engined aircraft roughly equivalent to the Gloster Meteor. With two GE I-A engines this made the first jet flight at Muroc Lake on 2 October 1942 just under a year from receipt of the Power Jets drawings. This was a truly impressive engineering performance which reflected American expertise, energy and capital. Whittle reckoned that the jet engine test facilities being built at GE were costing about twelve times what had been spent on equivalent facilities for Power Jets. (Incidentally, the original test cell for GE’s first Whittle-type engines is still preserved at the Lynn site.)

Sadly, the engineering and personal troubles in the jet programme in Britain, which have been discussed, meant that the W.2B engines were not considered adequate for flight there for some time after this, and in consequence the Gloster F.9/40 (Meteor) prototype first flew with de Havilland Goblin engines in March 1943, five months after the US achievement of its first jet flight, while the W.2B-powered prototype finally flew in June 1943.

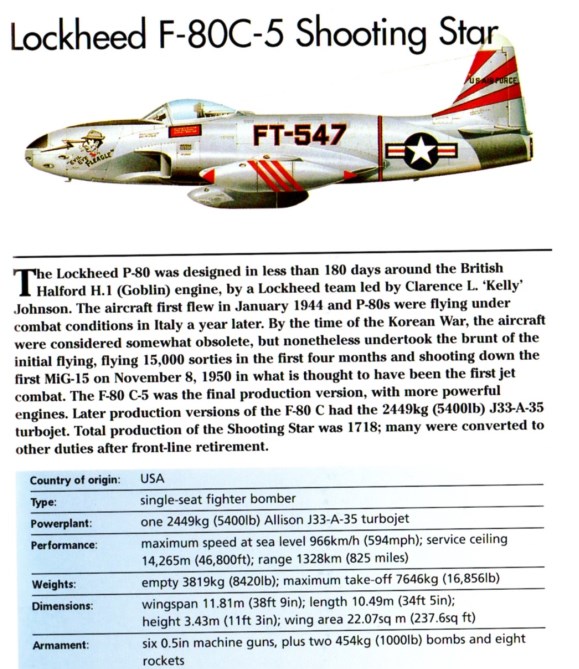

GE continued to develop the Whittle concept and came, like Rover and Rolls-Royce, to adopt a straight through combustion chamber layout. The resulting engine, the GE 1-40, first ran in January 1944 and initially developed between 3,800 and 4,500 lb thrust, and stimulated Rolls-Royce to start work on the Nene, intended as a 5,000 lb thrust engine. However, while Rolls-Royce and its licensees received only enough orders to build 4,375 Nenes, the GE 1-40 was passed for manufacture to the Allison company, which produced some 15,500 engines (under the service designation J33), principally to power aircraft like the Lockheed F-80 Shooting Star and the Lockheed F-94 Starfire. J33 production lasted until 1959. The size and length of this production run is eloquent comment on the difference in the economics of development and manufacture in the USA and Britain. (Even the Rolls-Royce Derwent, Rolls-Royce’s most successful Whittle-type engine, though built also by Pratt & Whitney in the US, as well as in France, Belgium, Canada and Australia, did not approach the figure for the GE engine, reaching a total production of 9,749 units.)

However, for GE, the I-40/J33 was the end of the line for the development of the Whittle concept. The same air force requirement for a 4,000 lb thrust engine which had brought on the 1-40 also suggested to GE an adaptation of the earlier axial flow turboprop, the TG-100, which had been developed at Schenectady at the request of Arnold’s Special Committee on Jet Propulsion. This pure jet engine, designated the TG-180, entered service as the J35, again manufactured by Allison. As the first axial flow engine to be used by the US Air Force it proved to be a significant post-war engine, powering aircraft such as the Republic F-84 Thunderjet, the Northrop F-89 Scorpion and the experimental Boeing XB-47 bomber.

As the war ended GE decided to concentrate gas turbine work at Lynn under the management of Harold D. Kelsey and to concentrate on axial flow engines. It also set out to win production orders rather than just design and development contracts. GE management predicted that by 1950 the total gas turbine market would be worth $35 million, of which the company might win 25 per cent. In fact, by 1950, GE’s share alone was worth $350 million, with their J-47 engine, which powered the North American F-86 Sabre, contributing much to their earnings. Today, like Rolls-Royce, GE is one of the three major global players in the civil and military jet engine market. Both owe their start in the business to the impetus provided by the wartime Whittle jet engine programme.