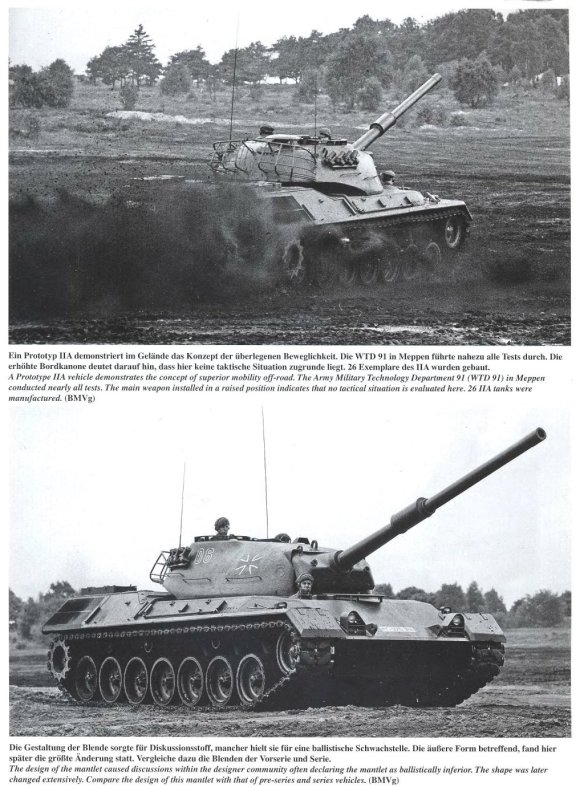

In some senses, Germany in the aftermath of World War II was an even more desolate place than it had been in 1919. Divided in two, with the Soviet Union occupying the eastern part of the country, and the Allies the rest, it was coming to terms with a new identity as well as recovering from losing the most devastating war in the history of mankind. The importance of the Federal German Republic in the west as a buffer against the Iron Curtain was not lost on the NATO powers, and at the end of 1955 the West German Army was created, being largely equipped by the United States, which sent first M47 and then M48 tanks. That same year, West reliant on US tanks at the time, laid down outline plans to jointly develop a main battle tank in the 30-tonne class, with the emphasis on mobility, rather than on protection. The venture was soon abandoned, and the two nations went their own separate ways. In West Germany, appropriate manufacturers with experience of building tanks during the preceding quarter century were grouped into two consortia and evolved competing designs, completing prototype vehicles in 1960.’Group B’ soon withdrew, largely because their product was more advanced and would therefore have taken considerably longer to get into production. This action left the field clear for the consortium led by Porsche, which produced a total of no fewer than 26 prototypes and 50 preproduction models of their new tank in the three years that followed. Production was then handed over to Krauss-Maffei in Munich, and a licence to build the tank for the Italian Army was granted to OTO Melara of La Spezia. The first Leopards, as the new tank became officially known, rolled out in September 1965. Over the following decade, over 4200 Leopard MBTs were completed, together with almost 1500 more chassis that were used in ARVs, armoured engineering vehicles and AVLBs, as well as in the Gepard anti-aircraft tank. The German Leopard went through a series of evolutions during this period, and Leopards were sold to a variety of NATO partners, as well as to Australia.

THE GERMAN LEOPARD

The Leopard 1 was rather more substantial than the original concept had envisaged, its combat-ready weight up to 40 tonnes despite the tank’s primary armour being just 70mm (2.75in) thick on the glacis and 60mm (2.4in) thick on the turret front and sides. The Leopard l’s hull was of welded construction, while its turret, from Rheinmetall, was cast as a single piece. The running gear was based on seven medium-sized dual roadwheels, with their axes offset to accommodate the bell-cranks that connected them to the torsion bars on which they were suspended. There were four track-return rollers, and the rear sprockets were driven via a W torque convertor gearbox by a 10-cylinder, 830hp multi-fuel engine from Mercedes-Benz. The engine gave the tank a maximum speed of 65km/h (40mph), and the entire powerplant/transmission package was designed to be replaceable in 30 minutes, even in the field, with the right equipment. The main armament consisted of the British 105mm L7A3 rifled gun, which somewhat surprisingly was neither stabilised nor precisely controlled in the original Leopards, although stabilisation in both axes and a fire-control computer were provided from the Leopard 1A1 variant onwards. The tank had co-axial and AA machine guns, in both cases 7.62mm MG3s. The basic ammunition load was 60 rounds of main gun ammunition (three in the turret, 57 in the hull) and 5500 rounds for the machine guns, the proportion of rounds of different types for the main gun being a matter for local decision. NBC and fire-suppression systems were fitted as standard, and a snorkel that mated with the commander’s hatch was available for deep-fording operations to a maximum depth of 4m (13ft). When the snorkel was brought into use, the tank’s apertures, in particular the turret ring, were rapidly sealed by means of inflatable rubber rings.

The Leopard l’s upgrade path followed a typical formula. The Leopard 1A1 gained not only the stabilisation system and fire-control computer but also a thermal sleeve for the gun tube, new design tracks, along with reinforced rubber skirts and modifications to the hatches and fording equipment. The Leopard 1A2 received a turret of higher specification steel, a better NBC protection system and image intensifiers for the commander and driver, while the Leopard 1A3 gained a new turret altogether, which had spaced armour and better ballistic contouring, including a wedge-shaped mantlet in place of the bulbous original. The Leopard 1A4 was fitted with spaced armour on the hull front as well. The Leopard 1A4 was more than 2 tonnes heavier than the original, but there was no noticeable degradation of performance.

The Leopard 2A7 + was developed and qualified for the new tasks of the German Armed Forces.

THE LEOPARD 2

Even before evaluation of the prototype Leopard 1 was complete, work had already started on the development of a successor, although it took a back seat to the West German-US MBT-70 joint project. When that was cancelled in January 1970, attention switched to the Leopard 2, and over the next five years, 16 prototypes were built to varying specifications. At around 55 tonnes, the Leopard 2 was considerably heavier than the Leopard 1, but not that much bigger. The extra weight went to improve the tank’s level of protection and bring it into line with the British Chieftain, which would clearly be the Leopard 2’s chief rival in the export market. The exact nature of the Leopard 2’s armour was kept secret for some time, and it was assumed to be a spaced laminate. But it eventually emerged that it was British Chobham armour on a steel frame, which accounts to some degree for the tank’s rather angular form. The other significant improvement over the Leopard 1 was in the main armament. A 120mm smooth-bore gun developed by Rheinmetall was chosen, for the reason that both fin-stabilised sub-calibre AP rounds and HEAT warheads function better if they do not rotate around their axis in flight. The Americans were to reach the same conclusion when the time came to select a gun for their own new MBT, and so did the French for the AMX- 30 replacement. But the British, who also increased the size of their MBT’s main armament to 120mm, kept faith with the rifled barrel.

A number of the Leopard 2 prototypes were fitted with hydropneumatic suspension, but in the end a torsion bar system with friction damping was chosen for the production tank, the rest of the running gear being identical to that of the Leopard 1. An improved multi-fuel engine, as originally developed for the MBT-70, was specified, its 1500hp providing the tank with a top speed of around 70km/h (43mph), which gave it a slight edge in that department over its predecessor. An order for 1800 Leopard 2s for the West German Army was placed in 1977, and the first vehicles were delivered the following year. Holland also acquired Leopard 2s, as did Sweden and also Switzerland, where they were known as Pz 87s and manufactured locally under licence. Spain also looked likely to acquire an improved version of the tank before the end of the 1990s.

LEOPARD UPGRADES

Like the Leopard 1, the Leopard 2 was to undergo successive upgradings as refinements were developed. A number of improvements became available in 1995, including a new tube for the main gun, extra armour and an improved fire-control system. But by that time, a much more major revision, involving a 140mm smooth-bore gun complete with auto-loader, had become practicable. This revision would allow the crew to be reduced to three and the turret to be downsized somewhat, while at the same time ammunition capacity would be increased and the tank’s firepower considerably enhanced. An improvement programme to incorporate this modification was put in train, but the first vehicles were not expected to emerge from it until towards the end of the first decade of the new century. A still more radical proposal called for the replacement of the traditional turret by an unmanned, fully automatic gun installation, remotely controlled by the commander/gunner who would be seated alongside the driver down in the hull. Although the technology to realise this certainly existed by 1995 – indeed naval guns of a very similar nature to the main gun of an MBT had been remotely controlled for many years – it was probably too radical a move to be implemented before 2010, even in prototype form. But even that could well mean that an improved Leopard 2 will be among the first of what will undoubtedly be the basic MBTs of the first quarter of the 21st century.