Various designs were considered.

No other Confederate ironclad has spurred so much continuing debate as the giant CSS Mississippi at New Orleans. That ironclad was a truly singular vessel, and both its unusual construction and powerful machinery installation drew much attention. The Mississippi was begun early in the Civil War and belongs with the early nonstandard design category of ironclads (such as CSS Louisiana) because it was intended for both offensive and defensive operations on the rivers and the sea. This warship was considered the Confederacy’s ultimate weapon in early 1862, if it could ever be finished.

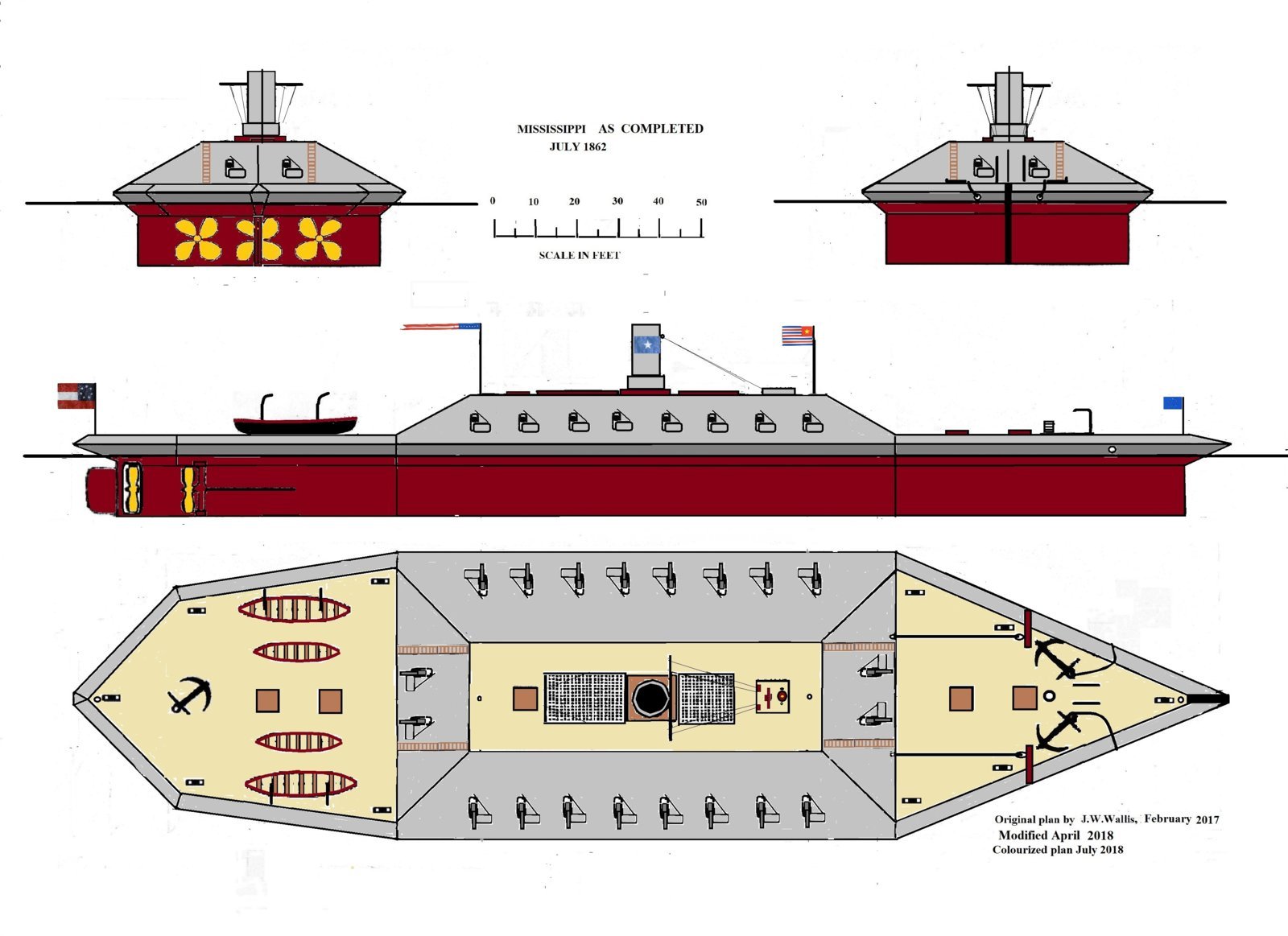

Construction of the largest and most powerful ironclad built in the South was begun at the same time as on the Louisiana at Jefferson City, Louisiana, just upriver from New Orleans. Nelson Tift (1810–1891) and his brother Asa (1812–1889) were originally from Connecticut but settled and made a name for themselves in Georgia and Key West. Nelson was successful as a planter, politician, and business entrepreneur by the time of the Civil War; Asa was involved in ship repair, warehousing, and merchandising in Key West. Neither had any shipbuilding experience, but both were prewar friends of Secretary Stephen Mallory, so they submitted plans for an enormous vessel to be driven by three screws and built without curved surfaces. This conception was a result of the brothers’ perceptive realization that the Confederacy lacked experienced shipwrights. The Mississippi was, therefore, constructed more like a ferry or a flat than a ship. A rough sketch drawn by the Tifts illustrates the design’s unusual conception and basic premise.

Many prominent naval officers and experts were on hand to observe and comment on the Mississippi’s form, and the plans were apparently approved by Constructor Porter. Some of the country’s most senior officers praised the Tifts’ concept. The Mississippi’s intended captain, Arthur Sinclair (1810–1865) touted the “formidable ship, the finest of the sort I ever saw in my life,” as a potential “terror of the seas” capable of “not only . . . clear[ing] the river of the enemy’s vessels, but rais[ing] the blockade of every port in the South.” Even Union Flag Officer David Farragut considered himself fortunate in not encountering a completed Mississippi during his campaign to seize New Orleans.

There were a few others who doubted, though. Lieutenant Robert Minor, the commander of the Naval Ordnance Works in Richmond, observed, “By model she is waterborne in centre and near before and abaft the broadest beam but bow & stern are not waterborne sufficiently. . . . On the whole the work seems to be very reliable, but all depends upon the principle of construction which remains to be tested.” Minor, despite his experience and technical knowledge, seems to have been in the definite minority of opinion regarding the Mississippi. It is uncertain to what extent the engineers and mechanics actually working on the vessel agreed or disagreed with his opinions. The citizens of New Orleans certainly believed the ironclad to be an invincible weapon that could deliver their city from the Yankee aggressors gathering in the Gulf of Mexico. The Tifts found no lack of support for their ambitious project, both in the Crescent City (New Orleans) and in Richmond.

The first plank of the Mississippi was laid on October 14, 1861, but construction lagged despite the simplicity of the ship’s design and its location adjacent to the Confederacy’s largest shipbuilding center. Among the most significant reasons for the delay was the Mississippi’s sheer size: 240 feet long between perpendiculars, 58 feet in extreme beam, and 15 feet in depth of hold.8 The length was increased by 20 feet during the course of construction when it was found during a consultation with experienced engineers that the existing boiler layout had insufficient grate and fire surface area to effectively propel the ship. The Mississippi’s original design called for “11 boilers 32 feet long and 42 inches in diameter, 2 return flews [sic], with mat [mud] drum 24 inches in diameter, steam driver [steam drum] 30 inches in diameter, about 40 feet long.” This already large system had to be upgraded to 16 double-flue boilers 42 inches in diameter and 30 feet long, capable of generating approximately 1,500 HP.

The Mississippi’s triple 11-feet-in-diameter propeller arrangement was one of the first such systems ever built and required powerful engines of 36-inch bore and 24-inch stroke turning at a maximum of 125 RPM.10 The stroke length was later increased to 30 inches during the revision of the boiler layout. The engines were high-pressure horizontal direct-acting and were optimistically projected to drive the Mississippi at 14 knots. Both boilers and engines, in addition to two doctor engines, two blowers, and two steam pumps, were constructed by Patterson Iron Works (formally known as Jackson & Company) of New Orleans.

The size of the Mississippi’s machinery and propulsion components caused great difficulty for the manufacturers. The giant center propeller shaft had to be forged by Tredegar Iron Works in Richmond. No foundry in New Orleans could produce the 50-foot-long wrought-iron piece required. In response to this dilemma the Tifts and Secretary Mallory contracted with Tredegar to forge the shaft from the burned-out steamer Glen Cove (sometimes called the Glencoe). The piece was painstakingly removed from the wreck, but no steam hammer in the Confederacy was capable of working such a large shaft, which had been built in the Northern states. Tredegar therefore had to resort to reworking it by hand. Two roughly 25-foot-long sections were eventually completed with some difficulty. Fifty men labored night and day for two months to complete the work, and a special railroad car was built just to transport the immense piece of iron to New Orleans. Much time was lost in the process, and the shaft and center screw had just been installed when the Mississippi was destroyed.

Forging the two wing shafts was also an odyssey. They were ultimately made by Clark & Company of New Orleans. Finding no complete shafts in the area and “no parties [there] . . . competent to make it” (i.e., no one apparently had the proper equipment), the Tifts contracted with Ward & Company of Nashville, Tennessee, to make the shafts. Negotiations with Ward about proper furnace and hammer equipment along with haggling over prices continued for some time but came to nothing. The Tifts next turned to Clark & Company which agreed to do the work. Clark then constructed a large steam hammer and furnaces in a new building for the purpose. Further negotiations with Leeds & Company of New Orleans resulted in an agreement to finish the shafts once forged, and progress was finally made. The shafts were 9 inches in diameter and about 40 feet long.

Manufacture, delivery, and installation of these pieces proved to be one of the most difficult aspects of the Mississippi’s construction. Nor was progress on the engines themselves turning out to be quick and simple. Under the advisement of a noted agent of Tredegar Iron Works, E. M. Ivens, and according to reviews of the machinery layout by Chief Engineer James Warner, many changes were necessary to strengthen the engine component castings. This included most major parts, such as the piston rods, cylinders, heads, bedplates, main pillow block bolts, crank pins, and eccentrics.

Patterson Iron Works agreed to furnish the engines and boilers after a consultation with Leeds had failed because that company was already occupied in manufacturing the shafting for the Arkansas and the never-finished Tennessee in Memphis. Leeds’s asking price for constructing the engines of $65,000 plus a build time of no less than four months was too steep for a short construction time. The Patterson works in turn offered to construct the machinery for $45,000 plus a bonus if the work was finished in ninety days, and received the contract. When the necessary augmentations and improvements to the boilers and engine castings were specified, Patterson added $20,000 in price for building the engines and $8,000 for the boilers.

The delays occasioned by the machinery revisions, and especially making the shafting, delayed the Mississippi’s launch date until April 19, 1862, just days before the Union captured New Orleans. By the fateful night of April 24–25 the boilers, smokestack, engines, center shaft and propeller, and wing shafts were on board, nearly complete but not connected. As a result, the Confederacy’s greatest warship was burned to prevent capture, after several attempts to tow the hulk upriver had failed. The Tifts had just days earlier estimated a completion date of May 1.

The Mississippi’s loss was a huge blow to Confederate morale and especially to the people of New Orleans. So great was the faith placed in its abilities that the anger and shock caused by the ship’s destruction nearly cost the Tifts their lives at the hands of a furious lynch mob. Most were convinced that only treachery by the Northern-born brothers could have caused the loss of the already legendary Mississippi.

Overall, of any Confederate ironclad, the Mississippi was affected in its construction most catastrophically by shortages of workers and materials and the limited abilities of local industry (despite it being abundant and accomplished). Even though the giant warship was of simplified design, there was not enough time to finish it, since New Orleans was captured at the end of the first year of war. As Secretary Mallory realized, there was great manufacturing potential in the Crescent City, but it took too long to build up to full wartime production. In the end the New Orleans firms’ inability to cope with increased industrial demand at the beginning of the Civil War resulted in the premature loss of the city and the Confederacy’s two most powerful ironclads, the Louisiana and the Mississippi.