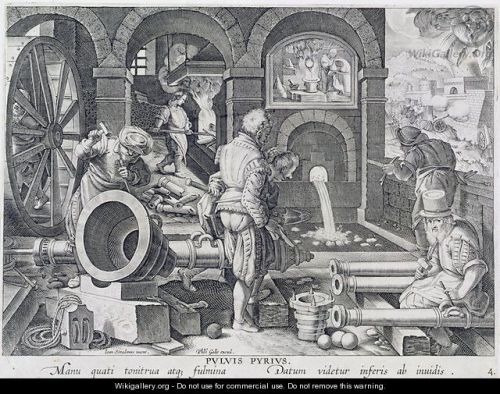

While barrels for small artillery pieces were easily cast as early as the 13th century, most larger cannon and the great bombards were constructed by the hoop-and-stave method. It was not until improved casting techniques and mature foundries were developed that large barrels could be made as single pieces of cast metal, first in iron and bronze, and later still in brass. By c. 1550 cast barrels of muzzle-loaders were cooled as a single, solid piece, after which the bore was reamed and a touch-hole drilled. Iron cannonballs were also being cast from greased, clay molds. Women from among the camp followers were frequently employed as laborers to dig the pit in which the mold was cast, gather faggots for the casting fire, dig out the gun after the metal cooled, and drag it to its siege site or for emplacement on the walls of a nearby castle or fort. During the 17th century Jesuit priests taught Chinese gunsmiths and generals up-to-date Western casting methods. English gunsmiths worked with local forges in India, and Dutch traders and governors brought the new technology to the Spice Islands, where guns of varying caliber were cast in local forges for use in Dutch fortifications and ships. Late medieval and early modern artillery varied greatly in size, caliber, and utility, but over time certain locales gained reputations as centers of quality gun manufacture. Permanent, large-scale foundries were set up and an international trade in cannon, it must be said, boomed. Northern Italy, Flanders, and Nuremberg were known for casting the best bronze guns. England and Sweden grew famous for casting cheap iron cannon in very large numbers that were nonetheless of excellent quality.

As cannon grew in importance in land and sea warfare in the mid-16th century the Spanish crown set up arsenals and foundries at Medina del Campo, Malaga, and Barcelona, and another at Seville in 1611. However, Spain lacked the skilled labor to meet its foundry needs-partly because its economy stagnated after expelling the Jews and Moors-and so remained dependent on additional purchases from the cannon markets of Flanders, Italy, and Germany. This lack of foresight and strategic planning cost Spain dearly as the Eighty Years’ War (1568-1648) led to an acute crisis in armaments that was compounded by war with Elizabethan England and later also with France. This lack of cannon hamstrung Spanish armies and fleets. Due to shortage of skilled labor, Spain’s foundry at Seville barely produced three dozen average caliber guns per year during the first half of the 17th century. In contrast, England, the Netherlands, and Sweden each had multiple foundries that cast 100-200 cannon per year. Spain was cut off from these northern markets by its wars with England and the Dutch rebels, although merchants in England sometimes sold to Spain in evasion of royal bans on exporting cannon outside the realm. Portugal also failed to develop a serious cannon production capability. Its chronic shortage of cannon for ships and fortified bases overseas was a significant factor in the loss of empire in Asia to the better armed Dutch and English in the 16th-17th centuries.

During the 15th and 16th centuries German foundries cast guns for use in Italy, by Spanish armies, and in the Netherlands. The Thirty Years’ War (1618-1648) created a huge domestic demand for cannon, but so disrupted the metals trade and skilled labor markets that German production declined. English, Dutch, and Swedish guns were imported and dominated that war. German cannon foundries recovered quickly after 1648, however, and soon challenged England and Sweden in international gun exports.

Netherlands foundries supplied the Dutch army’s growing need for artillery, which was driven by its prolonged war with Spain, its ultimately very large blue water as well as coastal navy, and the huge requirements of fortifying border towns as well as a growing overseas empire. The Netherlands also became a major exporter of first-rate artillery pieces of all calibers. This was not the case at first. The Dutch rebellion cut off the northern provinces from the industries of southern Flanders and the important metals market of Antwerp, which the Spanish still occupied. Over much of the last four decades of the 16th century, until foundries were built north of the rivers and skilled labor imported or trained, the Dutch imported cast iron cannon from England that were happily supplied by Elizabeth I to a Protestant ally against Spain. By 1600, Dutch foundries were so efficient they met domestic needs and began exporting ordnance to other European markets. Eventually, the Dutch set up a system whereby bronze ordnance was cast at home while iron cannon were cast in Dutch-owned foundries in Germany and at overseas bases. In Asia, the Dutch cast bronze cannon in Batavia for local use using “red copper” from Japan, but cast iron cannon wherein sufficient ore was available and nearby forests provided charcoal fuel.

Sweden and Russia were late starters in the foundry business. Both had great natural advantages-large deposits of iron, copper, and tin, and rich and abundant forests to produce charcoal for the blast furnaces of their great foundries-but only Sweden took full advantage in the 16th and 17th centuries to catch up to the rest of Europe, once social and military-cultural inhibitions to the adoption of gunpowder weapons were overcome. In Sweden the crown played a central role in encouraging casting of guns. Wrought-iron cannon were made from the 1530s; casting of bronze ordnance began in the 1560s; cast iron foundries overtook the older method of making iron cannon after 1580. By the time of Gustavus Adolphus, Swedish foundries were among the world’s best. Using both local labor and imported “Walloons” (gunsmiths from the Low Countries), Sweden emerged as a leading maker and exporter of cast guns in the 17th century. Tolerance of imported Catholic master gunsmiths in Sweden contrasted sharply with Spain, where Protestant gunsmiths eventually refused to work because they were not exempted from torments and execution by the Inquisition. The Dutch brought iron casting techniques to Russia, establishing a foundry at Tula in the 1630s. As skilled labor did not exist in Russia at that time, gunsmiths were imported from the Low Countries and Sweden, while unskilled peasants hewed the forests and worked the charcoal pits. Despite foreign aid, Russia remained a minor power in terms of both gun casting and artillery deployment until the great military reforms of Peter the Great around the turn of the 18th century.

English gun casting declined in the 17th century as the countryside was badly stripped of forests to feed the blast furnaces of the foundries and the shipbuilding industry. England’s long continental peace also sapped innovation and profit from its military industries. France similarly went into decline after an early lead in gun design and manufacture. The great French siege trains of the early Italian Wars (1494-1559) were no longer seen in the 17th century, as royal armies declined and skilled workers left for better-paying markets or to escape religious persecution of the French Civil Wars (1562- 1629), during which Frenchmen killed each other mainly with imported cannon. This situation was not reversed until Richelieu reestablished the French cannon industry to meet the demands of the Thirty Years’ War on land, and of a vastly expanded French navy.

Suggested Reading: Carlo Cipolla, Guns, Sails, and Empires (1965).