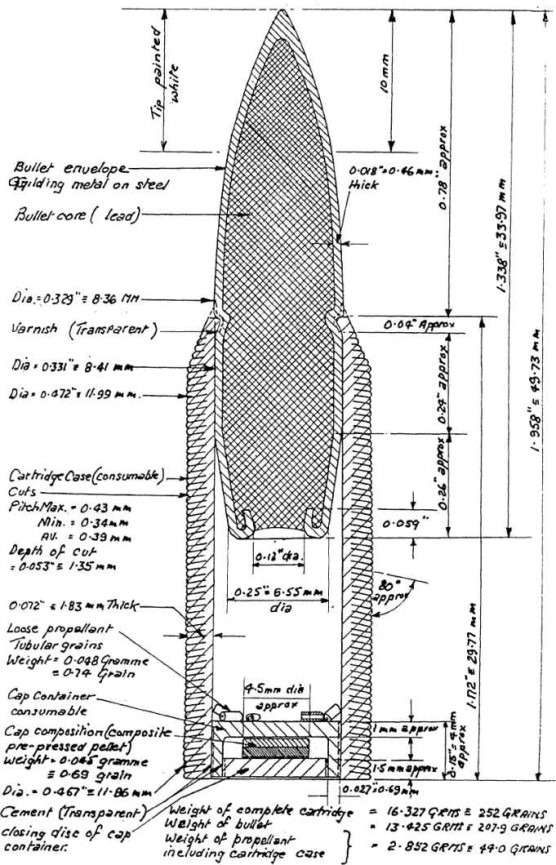

Some German research was far ahead of its time; this

remarkable drawing of a caseless cartridge – one using a solid block of

propellant to support the bullet instead of a brass cartridge case – was

discovered in 1945, but it was to be another 40 years before the idea was

successfully incorporated into a practical weapon system.

During World War II, Germany began an intensive program to

research and develop a practical caseless ammunition for military use, which was

driven by the rising scarcity of metals, especially copper used to make

cartridge cases. The Germans had some success, but not sufficient to produce a

caseless cartridge system during the war.

WWII – Germans experiment with caseless ammunition – Formed

Nitrocellulose (NC) employed to save “strategic materials” (brass). Steel cases were used instead.

Nitrocellulose or “guncotton” is formed by the

action of nitric acid on cellulose fibers. It is a highly-combustible fibrous

material that deflagrates rapidly when heat is applied. It also burns very

cleanly, burning almost entirely to gaseous components at high temperatures

with little smoke or solid residue. The burning rate of nitrocellulose is

dependent upon the pressure a pile of uncontained nitrocellulose will burn

slowly, with a high, bright flame, but when placed in a high-strength, sealed

container, the same material will burn very quickly, bursting the container. Nitrocellulose,

the primary component of modern, ignites at a relatively low temperature of

around 170 °C (338 °F).

Gelatinised nitrocellulose is a plastic, which can be formed

into many shapes of gun propellants such as cylinders, tubes, balls, and

flakes. The size and shape of the propellant grains can increase or decrease

the relative surface area, and change the burn rate significantly. Additives

and coatings can be added to the propellant to further modify the burn rate.

Normally, very fast powders are used for light-bullet or low-velocity pistols

and shotguns, medium-rate powders for magnum pistols and light rifle rounds,

and slow powders for large-bore heavy rifle rounds. These are known as

Single-base propellants.

Solid propellants (caseless ammunition)

A recent topic of research has been in the realm of

“caseless ammunition”. In a caseless cartridge, the propellant is

cast as a single solid grain, with the priming compound placed in a hollow at

the base, and the bullet attached to the front. Since the single propellant

grain is so large (most smokeless powders have grain sizes around 1 mm, but a

caseless grain will be perhaps 7 mm diameter and 15 mm long), the relative burn

rate must be much higher. To reach this rate of burning, caseless propellants

often use moderated explosives, such as RDX. (Caseless ammunition might be

considered a return to the mid-19th century, since the first practical

cartridge repeater, the “Volcanic” pistol, used a charge of black

powder in a cavity in the bullet base. This weapon was the direct ancestor of

the Henry and Winchester rifles, though they switched to metal-cased

ammunition. Some early rifles and revolvers also used combustible-paper

cartridges, but they required a separate ignition system.) The major advantages

of a successful caseless round would be elimination of the need to extract and

eject the spent cartridge case, permitting higher rates of fire and a simpler

mechanism, and also reduced ammunition weight by eliminating the weight (and

cost) of the brass or steel case.

While there is at least one experimental military rifle (the

H&K G11), and one commercial rifle (the Voere VEC-91), that use caseless

rounds, they are meeting little success. The caseless ammunition is of course

not reloadable (a major disadvantage in civilian markets, where reloading is

common) and the exposed propellant makes the rounds less rugged. Also, the case

in a standard cartridge serves as a seal, keeping gas from escaping the breech.

Caseless arms must use a more complex self-sealing breech, which increases the

design and manufacturing complexity. Another unpleasant problem, common to all

rapid-firing arms but particularly problematic for those firing caseless

rounds, is the problem of rounds “cooking off”. This problem is

caused by residual heat from the chamber heating the round in the chamber to

the point where it ignites, causing an unintentional discharge.

Belt-fed machine guns or magazine-fed submachine guns

designed for high volumes of fire usually fire from an open bolt, with the

round not chambered until the trigger is pulled, and so there is no chance for

the round to cook off before the operator is ready. Such weapons could use

caseless ammunition effectively. Open-bolt designs are generally undesirable

for anything but belt-fed machine guns and pistol-cartridge submachine guns;

the mass of the bolt moving forward causes the gun to lurch in reaction, which

significantly reduces the accuracy of the gun. Since one of the motivating

factors for the use of caseless rounds is to increase the rate of fire to the

degree that several shots can be fired to the same point of aim, anything that

reduces the accuracy of those first shots would be counterproductive. Cased

ammunition serves as a heat sink, to carry heat away from the chamber after

firing; the hot case carries away much of the heat before it can transfer to

the chamber walls, and the new case absorbs heat from the chamber, reducing the

risk of cook-off.