Various types of armoured support vehicle were developed during the Second World War and these contributed in no small part to the success of the Allied invasion of Europe in June 1944. The range of vehicles included ‘dozer tanks, armoured recovery vehicles (ARVs), beach armoured recovery vehicles (BARVs), armoured engineers’ vehicles (AVREs), bridgelayers (AVLBs) and armoured ramp carriers (ARKs), and various types of mine-clearance vehicle. Most were based on either the Sherman or Churchill hull and, despite their age, many remained in service with the British Army into the immediate post-war years. As these vehicles began to age, or became obsolete for other reasons, it was the Centurion chassis that was generally selected as the replacement.

The first to go was the old armoured recovery vehicle. When the Centurion started to enter service, it soon became apparent that a Sherman- or Churchill-based armoured recovery vehicle was not really going to be adequate to recover the near 50-ton weight of the new tank. Clearly a new recovery vehicle would be required. As an interim measure, a number of damaged Centurions were converted to tugs, or ‘towers’, in the British Army’s Commonwealth Base Workshop at Kure, Japan. Some were used in Korea, both for recovery and as supply and ammunition carriers, where it was shown that they were capable of hauling sledges loaded with up to 2 tons of ammunition up mountain sides. Other tugs were constructed by modifying obsolete gun tanks at 27 Base Workshop in Britain and at 7 Armoured Workshop BAOR.

However work had already started on designing a purpose-made armoured recovery vehicle using the Centurion hull. REME 13th Command Workshops (now 43rd) constructed a prototype at Aldershot during 1951 that was similar in concept to the old Churchill ARV Mk 2. There was a dummy turret and gun, and an 18-ton winch powered by the six-cylinder engine of a Bedford truck, but the crew compartment was cramped due to the need to provide a separate winch engine. Eleven examples had been constructed by the end of 1951, with a total of eight sent to Korea, and two to BAOR. Eventually, a total of 170 Centurions were converted to ARV Mk 1 configuration, with any problems that arose in service being ironed out as the conversion work continued.

Meanwhile, development work continued on the ‘official’ Mk 2 (FV4006) Centurion ARV. The first prototype for the Mk 2 (03ZR52) was constructed by Garner Motors of Acton in 1952, with trials continuing during 1953 and 1954. It was found that the removal of the turret reduced the weight of the machine to the point where its hill-climbing performance could be described as ‘remarkable’. The Bedford petrol engine that had been used to drive the winch on the Mk 1 variant was abandoned in favour of an electric motor powered by a 400V 160Ah generator that was in turn driven by a Rolls-Royce B80 No.1 Mk 2P or 5P eight-cylinder petrol engine, with a maximum power output of 165bhp at 3,750rpm from a displacement of 5,675cc. The generator was coupled to the winch via a roller chain. A huge spade anchor fitted at the rear was designed to be deployed using the main winch cable, and improvements were made to the layout of the winch, which was now rated at 30 tons for a direct pull, and to its roping arrangements, which now allowed pulls to the front or rear. or to either side by the use of pulley blocks. Considerable thought was given to the dissipation of heat produced by the winch and its power unit, which could result in overheating of the crew compartment, particularly when operating in high ambient temperatures. Although the problem was largely solved by means of fitting a large oil cooler together with a pair of fans forcing air through them, it was still necessary to limit the vehicle to five or six ‘pulls’ at full load. At the same time, trials were being carried out to determine the optimum construction of the steel wire rope used on the winch in order to obtain the best balance of life and wear.

A hull-mounted A-frame jib was also developed that could be attached to the front of the hull, allowing the ARV to remove and replace power packs in the field, and to provide a suspended tow to disabled vehicles.

Although a markedly better vehicle than the Mk 1, the hull remained cramped for the four-man crew, particularly the wireless operator, who had very little headroom when the hull was closed down, and it was occasionally necessary to remove the roof to gain access for maintenance of the winch. Production began in 1955 at ROF Woolwich and Vickers-Armstrongs, with the first example accepted into service in 1956; most of the 345 vehicles constructed were converted from obsolete gun tanks, and some were still in service as late as the end of the 1980s. In 1962 many of those in service with BAOR were modified to carry two spare 105mm gun barrels in place of the side stowage bins. This proved not to be entirely satisfactory because, although it reduced the need for accompanying trucks to carry the gun barrels, the ARV was not actually equipped to change the barrels and the attendance of a crane-equipped vehicle was still required.

A proposed Centurion ARV Mk 3 (FV4013) with a more spacious forward crew compartment, which would have placed the driver in with the rest of the crew, was never pursued beyond a design study.

During the amphibious landing stages of the D-Day assault there had been a second type of ARV designed exclusively for recovering drowned or disabled tanks and trucks on the landing beaches. Based on the M4 Sherman hull from which the turret and gun had been removed, and the sides raised to allow the vehicle to wade in up to 8ft of water, the beach armoured recovery vehicle (BARV or, occasionally, beach ARV), had shown itself to be enormously useful. The Sherman BARVs remained in service until the late 1950s but by this time they were proving unable to recover the heavier armoured vehicles that had started to enter service and, when the question of replacement arose in 1956/57, it seemed logical to use the hull of the Centurion. The Fording Trials Branch of REME used an obsolete Centurion ‘tower’ to produce a mild-steel mock-up along the lines of the Sherman BARV, operated by a four-man crew. The hull was extended forwards by about 5ft, with a large rope-cushioned pusher pad installed at the front,; this pad was subsequently replaced by a hardwood nosing block to reduce the danger of damaging landing craft. The prototype, which had been constructed from mild steel, was demonstrated at the Amphibious Trials and Training Unit (ATTU) at Instow in 1958/59 before being handed over to FVRDE for final development of the ‘proper’ armoured version. By the end of 1960 a batch of just twelve Centurion BARVs (FV4018) had been constructed at ROF Leeds using a mix of redundant Mk 1, Mk 2 and Mk 3 hulls. The overall height, with the armoured hull extension, was 140in, and the vehicle was capable of wading in a maximum of 114in of water, although at this depth the driver was effectively ‘blind’ and was obliged to rely on voice commands from the commander to direct the 40-ton machine. A set of lifting gear was also developed that could be attached to the hull of the BARV to enable it to lift out its own engine.

When the Army’s amphibious capability was phased out in favour of the Royal Marines, the Centurion BARVs were similarly reassigned, and two are known to have been taken to the Falkland Islands in 1982 along with the British Task Force.

At around the same time that the Centurion hull was being pressed into service as a BARV, the finishing touches were also being put to a Centurion-based bridgelayer. Early development work on armoured bridgelayers – or armoured vehicle launched bridges (AVLB) as they tend to be described these days – had been conducted using the hulls of Valentine infantry tanks, but most of those constructed and deployed during the Second World War were carried on a modified Churchill hull. As regards its post-war replacement, it had originally been intended to use the chassis of the FV200 series universal tank but when this was abandoned work had started on developing a Centurion bridgelayer; as early as 1946 experiments had involved mounting a lattice steel framework onto the hull of Centurion prototype number three to test the manoeuvrability of what was inevitably a somewhat extended vehicle. In 1952 a mock-up bridge was mounted onto a Centurion Mk 1 production hull, and by 1956 a working prototype had been constructed by Hudswell Clark of Leeds using a Mk 2 hull. User trials of this, and a second, modified prototype, this time possibly based on a Mk 7 hull, were completed by September 1958. By this time it had already been decided that the production vehicles would be based on redundant Mk 3 or Mk 5 hulls that would be reworked to bring them up to Mk 7 standard.

The Class 80 ‘bridge, tank, number 6’ consisted of four identical aluminium-alloy quarter sections topped with mesh trackways that were joined together in pairs to give a 52ft-long double-track bridge, capable of spanning 42ft. The bridge was carried in an inverted position along the length of the tank hull, and when the bridge was fully assembled the vehicle was almost 53ft long, so the bridge sections were generally carried on a small fleet of 3-ton trucks until required for deployment. In use, the four bridge sections were connected by two portal frames and a diagonal brace, and were attached to the launch arm at the nose of the vehicle. A lifting jib on the launch arm was used to assist in the assembly of the bridge sections, with brackets on the trackways used to attach the bridge to the arm. In-fill panels were carried on the sides of the hull, designed to be placed across the gap between the two longitudinal bridge components to allow smaller, wheeled vehicles to cross. During the launch operation, which took two minutes, the assembled bridge was simply lifted from its stowed position and rotated through 180 degrees vertically before being placed on the ground behind the tank, at which point it was disengaged from the mechanism and the tank would withdraw. Recovery was more or less the reverse of the launch process, taking four minutes.

The hydraulic equipment required to launch and recover the bridge was powered by a Rolls-Royce B40 No.1 Mk 5P four-cylinder petrol engine, with a power output of 62bhp at 2,800rpm. The auxiliary engine was connected to a Towler Brothers hydraulic pump by a drive shaft taken directly from the flywheel, and was controlled electrically by solenoid-operated valves. Both the auxiliary engine and the hydraulic equipment were housed inside the fighting compartment.

The resulting vehicle weighed 49.6 tons with the bridge in place but nevertheless was capable of a top speed of 20mph on the road. The first pre-production Centurion bridgelayer was completed by ROF Leeds in early 1960 and, following acceptance trials, production proper started in 1961 and continued until 1963, with many going for export. The sheer size of the machine and the resultant lack of manoeuvrability meant that it was unable to keep up with the gun tanks in urban areas, not least in West Germany where most were deployed. Nevertheless, the vehicle remained in service until 1974, when it was replaced by the Chieftain bridgelayer that deployed a more versatile scissors bridge.

The Royal Netherlands Army operated a Centurion-based bridgelayer of its own design, mounting a forward-launched scissor bridge similar to that fitted to the US Army’s M48 and M60 bridgelayers.

Churchill tanks had also been modified to act as armoured ramp carriers (ARKs) – effectively, a rapid assault bridge – during the Second World War and, although these also remained in service into the immediate post-war years, by the late 1950s they were showing their age. The FVRDE-designed replacement (FV4016) used the hull of a Centurion Mk 5 from which the turret and gun were removed, with a roof plate covering the turret ring; the commander was relocated inside the hull alongside the driver. Folding ramps were attached to either end of the hull, and a trackway was fitted across the top. In use, the tank was driven into the centre of a ditch or trench, or up against a sea wall, and the ramps were folded out hydraulically at either end to form a Class 80 continuous bridge, with the hull of the tank itself forming the centre section. In travelling configuration, the length of the ARK exceeded 34ft and, when deployed, the 81ft-long bridge gave a useful span of 75ft and a width of 14ft across the ramps.

There was some concern that the increased weight of the ARK would place greater loadings on the rear wheel stations and development trials for the ARK were carried out in 1957, with particular attention paid to the suspension loadings. Both Mk 5 (although in actual fact it was a Mk 3 hull that had been weighted to simulate a Mk 5) and Mk 7 hulls were trialled, with the objective of determining whether or not the performance of the vehicle was reduced by an unacceptable degree. The report published at the conclusion of the trials stated that the convoy performance of the Centurion ARK would be reduced by some 50–75 per cent when compared to the gun tank, and that tyre temperatures would become critical after running for 90 minutes, as opposed to 120–150 minutes for the latter.

The Centurion ARKs, which were constructed by ROF Leeds, remained in service until 1975, by which time this type of equipment was considered to be obsolete.

Another variant of the ARK was the so-called Centurion ARK mobile pier (CAMP), which was designed to provide a central pier support in the centre of a waterway that could accept two ‘number 6’ tank bridges. The ramps were omitted, leaving only the central trackway in place.

During the Second World War Churchill tanks had also been converted to the ‘armoured vehicle, Royal Engineers’ (AVRE) role, being used for the demolition of structures such as pillboxes and gun emplacements, and for carrying a fascine bundle that could be used to allow ditch crossing. Development of the Churchill AVRE continued into the post-war years, but by the end of the decade attention had switched to the Centurion as a basis for such a vehicle.

The first proposals for a Centurion-based AVRE date back to September 1950, when a prototype was produced at the Fighting Vehicles Proving Establishment (FVPE) using the hull of Centurion prototype number four (T352413, subsequently renumbered 02BA58), and the turret of a Centurion Mk 1 into which had been installed a 95mm howitzer. A full-width (13ft) hydraulically operated compact ‘dozer blade, produced by the Newcastle company T.B. Pearson & Sons, was fitted to the nose, with a cradle to carry the fascine bundle above it. These changes effectively shifted the centre of gravity of the 53-ton vehicle forward of the centreline of the suspension by around 6in. In 1954/55 there were further trials with a Centurion Mk 3 (02BA12) that had been weighted to represent a Centurion AVRE carrying a 5-ton fascine bundle on the cradle, bringing the total weight up to 55.6 tons. The trials were intended to report on any negative impacts on the suspension and track system, and the vehicle was tested across 146 miles, with the speed limited to 12mph on the road and 8mph across country. It was concluded that carrying the fascine bundle ‘causes no apparent damage to the suspension of the vehicle’. Trials were also carried out with a modified Mk 3-based AVRE that had been fitted with simplified gun controls.

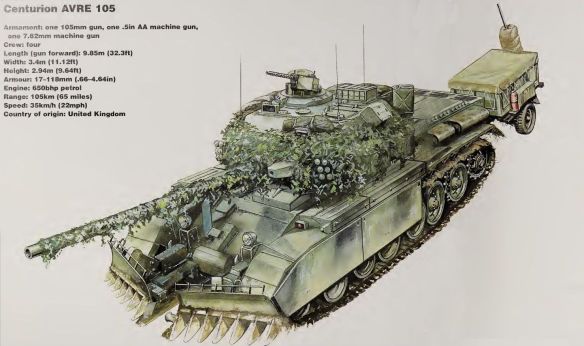

Despite all these trials, problems with development and a shortage of materials meant that the final prototype, by now using the hull of the Centurion Mk 7 gun tank, did not appear until August 1957. By this time the vehicle featured a front-mounted ‘dozer blade, the rams for which were fitted into armoured boxes on the nose plate; a removable 10-ton jib, eventually mounted on a ball and socket arrangement; a cradle for carrying a fascine bundle, with the release effected via blow-out pins; and a 1.5-ton hydraulically operated winch. Hydraulic controls for the ‘dozer and winch were provided in the driver’s compartment. Definitive development trials, concentrating on the hydraulics and the ancillary equipment, were initiated in 1959 but there were further delays before production finally got under way in 1963. (See colour plate 8, a and b.) By this time a shortage of Mk 7s meant that the production vehicle was to be based on the hull of the Mk 5, into which was fitted a 165mm L9A1 gun firing a heavy demolition charge, but lacking the automatic stabiliser equipment found on the gun tanks. There was also an L3A3 or L3A4 0.30in Browning machine gun – the use of this gun on the AVRE was something of an anomaly since it remained in service for this application long past its demise elsewhere in the British Army. Just forty vehicles were constructed, some of which were based on the hulls of Centurion Mk 12 artillery observation posts fitted with a Pearson’s mine plough in place of the standard ‘dozer blade, and retaining the 105mm gun of the original. A jettisonable 15-ton four-wheel trailer (FV2721A) was also developed for use with the Centurion AVRE to carry either a fascine bundle or trackway.

Although the AVRE was equipped with a hydraulic ‘dozer blade, back in 1958 a requirement had been issued for fitting such a blade to a Centurion gun tank, but it was to be a further three years or so before the vehicle (FV4019) started to enter service. Designed to replace the Churchill- and Centaur-based ‘dozers, the latter lacking a turret, the Centurion ‘dozer was based on the Mk 5 gun tank to which had been fitted a hydraulically operated bulldozer blade manufactured by Pearson’s and identical to that fitted to the Centurion AVRE. The blade was operated via a hydraulic pump manufactured by H.M. Hobson, and the equipment was supplied as a prefabricated ‘dozer kit that could be fitted to either the Centurion or the Conqueror, with the hydraulic pump driven by the main engine. The main gun remained operative, although there was some reduction in the number of rounds that were carried, and both Mk 5 tanks, equipped with the 20-pounder (83.4mm) gun, and Mk 5/1 tanks with the 105mm L7 gun, were converted. With the ‘dozer equipment in place, the weight was increased to 52.6 tons, and the tank became somewhat nose heavy and unstable when firing to the rear; the additional weight also precluded up-armouring.

There were initial problems with hydraulic connections, but it was a useful piece of kit, and the report of the development trials stated categorically that the ‘dozer-equipped Centurion was ‘the first armoured bulldozer to exceed by a considerable margin the earth-moving capacity of the Caterpillar D8’ (bulldozer), shifting 300yd3 of soil an hour compared to just 200 for the Caterpillar, and it was able to dig a ‘hull-down’ defensive position for a tank in light soil in just 7 minutes. It was also capable of removing concrete and steel road-block obstacles, hardwood trees up to around 36in diameter, and of breaching reinforced concrete walls.

Centurion ‘dozers were also exported to Australia and Denmark.