The competitive system of target practice repeatedly exposed limitations in the fire-control system. Range finders often gave inaccurate initial estimates, leading to erroneous range rates and poor shooting. It took time to correct these errors and bring the salvoes onto the target. Because the exercises were timed—reflecting the need to hit the target quickly in battle—they could end before some ships scored any hits. Fire-control officers faced a lot of pressure. They had to be able to rapidly synthesize many data points (estimates of target range, range rate, spotting corrections) from a variety of sources (range finders, plotting and tracking boards, electronic telephones) to determine how to bring the guns on target. In some practices, they were not up to the task. There was too much information to process and synthesize in too little time.

The Navy needed to augment the system with a device that could gather together all these different sources of information, process them, and build a model of the target’s movements in real time. With a more comprehensive model, officers could focus on bringing the guns onto the predicted point and then refining the model based on feedback from spotting, range-finder ranges, and observations of target bearing. Rear Adm. Joseph Strauss, chief of BuOrd, spoke to this goal in his annual report for 1915: “As the fighting ranges increase, the necessity of a simple yet efficient means of keeping the range becomes more pressing, and the bureau has experimental instruments under construction which it is hoped will aid materially in the solution of this problem.” He addressed the same theme the next year: “Increased attention is . . . being devoted to the development of instruments that will get and keep the range with the greatest precision possible, having in mind conditions as they will probably exist in battle as indicated by reports of naval engagements in the present war.”

Reports from World War I suggested the Navy was behind British and German standards; they were opening fire at 20,000 yards and fighting beyond 15,000. The Navy’s 1914 practice firings were only from 10,000 to 12,000 yards. Greater ranges would require better tools. The fire-control board of 1916 was more specific in its recommendations: move away from the Mark II Plotting Board, which was then in general use.

The rate of change board (Mark II plotting board) . . . provides a sample method of plotting a curve of rate of change, using range finders and spots. With sufficiently good observations the past rate of change can be obtained and used in connection with the sight-bar range while “straddling” for holding the range. Excellent results have thus been obtained on long range target practices. Such practices however, are necessarily restricted, both in rate of change practicable and, more particularly, in changes in the rate of change,—as compared with what may be expected with own ship and target running at high speed and on varying courses,—as they both may do in station keeping and . . . in attempting to evade fire. For these latter conditions, results from the rate of change board are likely to lag too seriously for efficient range keeping.

The board recommended keeping the range automatically with a mechanical “range keeper” that could model the movements of the target and maintain the firing range through a variety of complex maneuvers. The board argued that the system should work in such a way that “changes in range due to own ship’s movements may be applied as nearly as automatically as practicable, to the end that the ship may be free to change course and speed without loss of accuracy.” Its members thought that true-course plotters could allow for this but that what was needed was a new device, a mechanical, rangekeeping computer.

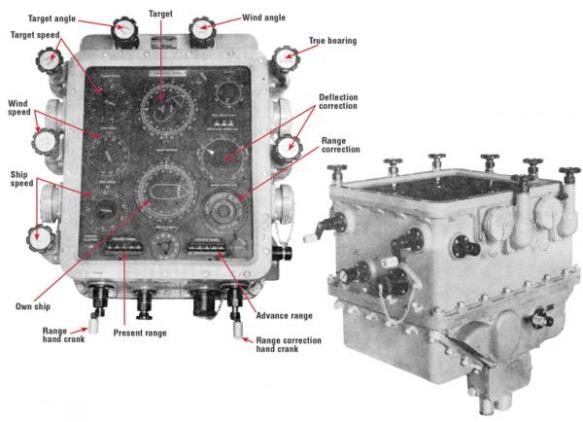

The Ford rangekeeper was the solution. It was the brainchild of Hannibal C. Ford, an extremely talented mechanical engineer who had been introduced to the challenges of fire control by Elmer Sperry. Ford joined Sperry’s company in 1909, helping to develop the gyrocompass and becoming the lead engineer for Sperry’s battle tracer. In 1915, Ford resigned from Sperry’s company and founded the Ford Marine Appliance Corporation, later renamed the Ford Instrument Company. In 1916, Lt. Cdr. F. C. Martin, responsible for the Fire Control Section in BuOrd, began discussing the idea of a rangekeeping device with Ford.39 These discussions led to Ford’s first product, the Navy’s Rangekeeper Mark I.

Ford’s rangekeeper sought to address two critical problems with the Navy’s existing system. The first was that the tracking and plotting mechanisms were manual, slow to develop a solution, and error-prone; their feedback loop took too long. The second problem was that there was no automated means of controlling for the movements of the firing ship; if it turned or maneuvered, the fire-control solution—the range rates that had been developed—had to be recalculated. Ford solved these issues with an automatic calculation mechanism that provided more rapid feedback to the fire-control officer. The rangekeeper reduced his cognitive burden, allowing him to devote more concentration to the model and the corrections necessary to bring the guns onto the target.

The rangekeeper integrated two separate internal models, one for the motion of the firing ship and another for the target. From these models, it continuously generated a series of outputs required by the fire-control system, including the range and deflection (or bearing) settings for the guns. It integrated well into the existing fire-control system, providing a much more accurate model without the need for redesign. The required inputs were readily available (like firing-ship course from the gyrocompass) or already being gathered by the system (like target range and speed). Some of the inputs, like target bearing, could be provided automatically using the data-transmission system. Because of the smoothness with which the rangekeeper integrated into the existing system, plotting devices could continue to serve as a backup if it failed, and established practices—like spotting—did not have to change.

What did change, and changed significantly, was the way the fire-control officer assessed the accuracy of the model of the target’s movements. Ford designed his machine to provide a great deal of feedback about the quality of its internal model. On its face was a graphical representation of the target. This representation built on the approach Reeves and White introduced in the change-of-range projector. A disk representing the target rotated to reflect its estimated course, and a “button” along its length indicated its estimated speed, just as the projector’s “pin” had done. Two wires were placed over this representation. One wire indicated the observed range to the target and the other the observed bearing. If the rangekeeper’s model was accurate, these two wires would intersect over the target speed “button.” If they did not, the operator knew immediately that corrections were necessary; he could get a sense of what they might need to be by which wires were off and by how far.

This level of feedback was possible because Ford’s design separated the motion of the firing ship and that of the target. Although similar computing devices were developed in the early years of the twentieth century, Ford’s was the only one to maintain this separation. It allowed fire-control officers to check and refine the accuracy of their solutions before opening fire. Previously, spotting was the only real feedback loop in the system. With the rangekeeper, observations of the target provided a constant check of the developing model, allowing it to be enhanced continually and permitting more accurate fire. Ford’s decision was likely influenced by his discussions with Martin and his work with Sperry’s battle tracer, which also separated the motion of the firing ship and the target. Regardless, the choice was crucial and one of the most valuable features of the rangekeeper.

The value of feedback was reflected in the initial revisions to the instrument. The first models automatically took in target-bearing information from the data-transmission system. This was quickly replaced by a follow-the-pointer mechanism allowing a manual check. The rangekeeper generated its own prediction of target bearing and displayed it on the face of the instrument alongside the observed bearing. If the generated bearing and observed bearing did not agree, the solution could quickly be corrected. A second modification added a graphical plotter that automatically recorded observed ranges. These could be compared with ranges generated by the instrument, giving the operator a quantitative sense of necessary corrections and augmenting the information from the horizontal wire in the instrument’s face. Rapid feedback was an integral aspect of the rangekeeper’s design and a core reason why the Navy considered the Ford superior to other candidate devices.

The rangekeeper was initially tested on the battleship Texas in 1916, and a board was assigned to assess the results. The board’s report was very positive; it considered the rangekeeper superior to any other method and recommended installation on every battleship. Production versions started being installed in 1917. The first ships to receive rangekeepers were the most modern battleships. By early 1918, each of the Navy’s dreadnoughts had at least one system. By the spring of the same year, eleven of the older predreadnoughts had them as well.

However, the reception in the fleet was not as enthusiastic as might have been expected. Although the rangekeeper offered a dramatic improvement in potential accuracy, the simplistic conditions of gunnery exercises did not always require such a sophisticated tool. BuOrd was compelled to respond to criticism from the fleet and justify its decision to adopt the new device: “The machine was designed to deal with difficult conditions we expect to arise in battle, where changes of course and speed will be frequent and vision poor. It is impossible to reproduce anything well like this in target practice, and, therefore, not an easy matter to get people to realize the importance of taking these conditions into consideration.” Experience in World War I and exposure to the rigorous gunnery practices of the RN led to more challenging exercises. Combined with increasing familiarity with the rangekeeper, these helped the fleet embrace its use.

The introduction of the rangekeeper gave the fire-control system a sophisticated brain; self-synchronous data-transmission systems gave it a more effective nervous system. Sperry’s systems had two specific limitations. They lacked the precision for transmitting range data, and because they transmitted information in a series of steps from a “zero” level, they had to be periodically synchronized—set back to zero—to ensure alignment. If they became misaligned in battle, the ship would have to revert to telephonic communications. In 1918, BuOrd began looking for a solution that supported automatic synchronization and increased precision.45 By this time, Cdr. W. R. Van Auken had replaced Lieutenant Commander Martin in the bureau’s Fire Control Section. Van Auken discussed the problem with Ford. The bureau’s history of World War I describes what happened next:

When the elevation system was discussed, all thought was expended toward a design using synchronous motors. About January, 1918, Mr. Ford was called into conference by Commander Van Auken and the manufacture of this system was placed in his hands. In May the first unit, the range converter, was accepted. This was modified as required and in September, 1918, the New Mexico obtained the first synchronous follow-the-pointer elevation installation. This Bureau-Ford system is now being installed on all major ships.46

The introduction of self-synchronous systems allowed the Navy to reconfigure the transmission of data the same way it did telephonic communications, dramatically increasing the flexibility and safe-to-fail characteristics of the system. Switchboards were expanded to allow the dynamic reconfiguration of data-transmission systems. Through the switchboard, any director could become the primary source of target bearings; if two targets were being engaged, the system could be divided and two directors used simultaneously, each driving a separate rangekeeper. Different turrets could be connected to different directors and rangekeepers, depending on the circumstances. The ability to self-synchronize allowed the system to be reconfigured on the fly. The advantages were so great that self-synchronous systems for elevation and bearing became the standard in new ships and were retrofitted into existing ones.

The ability to reconfigure the system dynamically and cross-connect components created new opportunities. A feature known as the “stable vertical” capitalized on this potential and addressed a major source of human error. Even if the solution developed by the rangekeeper was correct, the accuracy of individual salvoes could vary because of the reaction time of the director operator. He had to fire the guns at the right time in the ship’s roll, usually when the horizontal wire of his telescope was parallel to the horizon. If he pressed the firing key too early or too late, the shells would miss the target. If the horizon was obscured, either by smoke or poor visibility, this was much more likely. The stable vertical solved these problems. It was a gyroscopically stabilized artificial horizon that could be used when the actual horizon was obscured. When connected to the fire-control system, the stable vertical could fire the guns automatically when the ship’s deck passed through the horizontal plane, eliminating errors due to the director operator’s reaction time or view of the horizon.

Introduced on the Navy’s Colorado-class battleships, the stable vertical increased the accuracy of fire, particularly at longer ranges—where minor errors had a greater influence—and in conditions of poor visibility. Because the fire-control system could be easily reconfigured through the switchboard, it was simple to incorporate the stable vertical into the system and have it fire the guns. The stable vertical was a modular upgrade made possible through the system’s open architecture. As older ships were modernized, it was retrofitted into them, and once sufficient experience had been gained, it became the primary indicator of the ship’s inclination for fire-control purposes, replacing the eyes of the director operator.

The final ingredient in the Navy’s standardized fire-control system was the creation of a specific language for communicating information between and among the various stations. Precise details had to be communicated quickly, clearly, and succinctly over the telephone circuits. Each circuit was a party line, meaning every station connected to the line could hear all the others and transmit information over the circuit to any. On a battleship, there could be as many as twenty-one stations patched into the captain’s battle circuit. It was essential to keep communication brief and convey as much information as possible in a short amount of time, as explained by a 1940 manual:

The development of efficient communications is one of the most important problems in the training of a fire control organization. . . . Successful communication requires, first . . . a satisfactory system of telephones and other transmitting instruments, and second, properly trained personnel. . . . The second requirement, however, is not one that can be met by mechanical perfection of instruments, or by prescribing hard and fast rules for personnel. It demands careful indoctrination and training so that every individual is familiar with the problem at least as it concerns his immediate station and those with which he is in communication, and is prepared to act intelligently in any contingency.

The fire-control system required a communication method with a very high signal-to-noise ratio. Existing English-language structures were insufficient to meet the need; the manual continued, “The demand for brevity has resulted in the development of numerous stereotyped phrases and modes of expression. They constitute what may be termed a ‘fire control language.’”

Specific rules—representing an increased level of constraint—were developed to guide communications. Numeric values were transmitted by enunciating each digit separately, except in cases when the last two digits were zero, said as “double oh.” A range of 13,350 yards, for example, was communicated as “Range one-three-three-five-oh.” A range of 29,000 yards was, “Range two-nine-oh-double-oh.” Spotting corrections were similarly constrained. “Up” increased the range; “down” decreased it. Deflection corrections were “left” and “right.” To prevent confusion between the two, “oh” was always added immediately after the word “right.”

This language significantly reduced the length of communications and the time necessary to convey information. Additional rules governed how to address specific stations, how to acknowledge information, and how to transfer responsibilities from one station to another. The development of this language triggered a new level of complexity and standardization within the Navy’s fire-control system. It was a new enabling constraint that enhanced the capabilities of the system and broke symmetry with what came before.