Development of the B.E.2 continued and by October 1915, a new variant, the B.E.2d, had been developed incorporating dual controls. In order to accommodate the rudder cables and torque tube connecting the two control columns, the main petrol tank, which in earlier variants had been located under the observer’s seat, was replaced by an additional tank in the decking between the cockpits and a blister-shaped gravity tank under the upper port wing. The capacity of the existing gravity tank in the decking behind the engine was increased from fourteen to nineteen gallons, bringing the overall capacity up from thirty-two to forty-one gallons, providing a useful increase in range and endurance. The rigging notes for the type included the provision of an additional six feet of shock cord to each wheel to cope with the additional weight of fuel. However, these changes had an adverse effect on the machine’s unspectacular rate of climb, almost doubling the time taken to reach 6,000 feet. Although over 650 B.E.2ds were ordered, only a small number found their way to France, the majority serving with training units where their dual controls were an advantage and poor rate of climb no great handicap.

Research indicated that under extreme conditions the existing fin might be of insufficient area to prevent an involuntary spin developing. Most pilots held this manoeuvre in dread as the recovery procedure, although simple, was not then on the syllabus at flight training schools. Experiments were conducted with a number of fins of increased area, these experiments later being fully described in a confidential paper presented by O’Gorman to the Advisory Committee for Aeronautics. B.E.2c, 1688, which was retained at Farnborough as a test vehicle, was fitted with several experimental fins of differing surface areas to evaluate their effect and the most effective selected.

In January 1916, B.E.2c, 2026, was fitted with the proposed new fin having a curved leading edge that increased its surface area from five square feet to eight and was sent to the Depot at St Omer for evaluation. Service pilots confirmed that it improved directional control and, most importantly, helped prevent incipient spins. The new fin was therefore adopted and fitted to all machines completed from then on as well as many that were in service. 2026 served with 12 Squadron, but on 16 May, crashed while landing and although repaired was not considered fit for further service and was returned to England to serve as a trainer.

The employment of the B.E.2c in a ground attack role, especially during the Battle of the Somme, inevitably led to aircraft being lost to small arms fire from the ground. Perhaps to avoid further accusations that crews were being sent to war in inadequate aeroplanes, a scheme was devised where the forward fuselage was fitted with sheet steel armour plate from the nose to the rear of the pilot’s cockpit. The slab-sided armour, which did nothing to improve the machine’s streamlining, weighed around 440 lbs and seriously handicapped the machine’s performance. Nonetheless, at least fifteen machines were fitted with the armour and saw service on the Western Front. 2028, which had originally been built by Sir Armstrong, Whitworth & Co. Ltd., was with 6 Squadron by 9 September 1916 as an armoured machine. 2122 went to 8 Squadron and at least one example served with 15 Squadron, remaining in service until the spring of 1917 carrying out ground attack and special reconnaissance missions. Other examples known to have been fitted with armour include 2713-2716 and 4093.

Ongoing research at Farnborough revealed that wings with outwardly raked tips were, at the speeds at which aeroplanes then operated, considerably more efficient than any other wing tip shape. Similarly, it was known if wings were superimposed as in a biplane, each affected the efficiency of the other reducing lift and increasing induced drag. Yet the ideal arrangement, the monoplane, if employing the shallow aerofoil sections of the day, required so much additional bracing to maintain rigidity that any aerodynamic advantage was lost. The best compromise was to reduce the span of the lower wing, eliminating struts and wires, and to increase the span of the upper wings, bracing the overhang from kingposts.

A new variant, the B.E.2e, was designed with a new, smaller horizontal tail and with wings following the new arrangement, the span of the upper wing increased by four feet and that of the lower wing reduced by six feet. The wings were rigged at a constant angle of incidence without any washout as the new raked tips were thought sufficient to prevent wing tip stalling. The ply covering to the top and bottom of the fuselage was eliminated and wire bracing substituted. Some fuselage members were changed from ash to steel tube, principally to alleviate problems experienced in obtaining sufficient supplies of good quality ash.

In February 1916, B.E.2c, 4111, was test flown fitted with the new wings and the improvement in both speed and climb was quite dramatic. Lateral control was considered to be ‘very much better’ and landing ‘more easy’. The prototype was first tested fitted with an experimental up-rated RAF1b engine, achieving a top speed of 97 mph, boosting expectations of its improved performance. Since it was decided that this engine was not to be put into production, 4111 was fitted with a standard production 90-hp RAF1a (No. 22971/WD1009). Thus powered, the B.E.2e was 10 mph faster than the B.E.2c and this, together with the improvements in handling, was more than sufficient to ensure that it was put into production as soon as possible. Not only were a total of 1,000 examples placed on order with various contractors, but instructions were given to those building the B.E.2c and B.E.2d to fit the improved wings and tailplane. However, when the completed machines were received, complications arose for it was realised that manufacturers were producing three different machines. All had the same wings and tail surfaces, and looked very similar, but each had a different fuselage. To simplify the matter, especially when it came to the ordering of spares, it was therefore decided that the designation B.E.2e would apply only to those machines built entirely to the new design. Those that had originally been ordered as B.E.2c with the original fuselage would be designated B.E.2f and those with the B.E.2d fuselage would be known as the B.E.2g. Around 200 of each variant were eventually produced. The new wings were viewed with some suspicion, pilots wrongly thinking them structural unsound and a rumour circulated that the extensions would be damaged by violent manoeuvres. Experience proved this to be untrue and confidence in the new type returned.

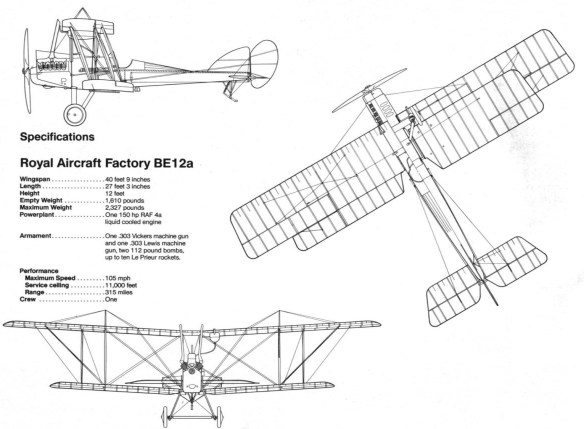

B.E.10 was designed to carry out similar duties to the B.E.2 and had a deeper fuselage built around a framework of steel tubes. Four were ordered from the British & Colonial Aeroplane Company, but the order was cancelled when it was decided to concentrate on the B.E.2c. B.E.11 never progressed beyond the concept stage and no details of it survive. B.E.12 was a high-speed, single-seat scout conceived in the summer of 1915 and created by the conversion of 1697, the last of a batch of Renault-powered B.E.2cs built by British & Colonial. It was fitted with an RAF4a engine, a twelve-cylinder development of the RAF1 design developing 140 hp, the modifications to the engine mounts and increased fuel tank capacity taking up space created by the elimination of the front cockpit. Its first flight was made on 28 July 1915 and production examples began to arrive in service by the beginning of 1916. Although as vulnerable as the B.E.2c upon which it was based, the B.E.12 did good work both on long-range reconnaissance missions and as a bomber. Some were fitted with a forward-firing machine gun once a suitable synchronisation gear had been developed but were never intended as fighters, the stability inherited from the B.E.2 reducing their speed of manoeuvre.

The B.E.12 was still in production when the B.E.2e was introduced and was also fitted with the new wings to become the B.E.12a, its performance being similarly improved. The B.E.2 even managed to contribute to its own replacement, both aeroplanes which eventually superseded the B.E.2c employed B.E.2c components in their original form. The Bristol F2a, from which the famous Bristol Fighter was developed, first flew on 9 September 1916 fitted with the wings of a B.E.2d. At the time, the company was building the wings under contract although purpose-designed wings were substituted before the type was fully developed for production.

Designed by John Kenworthy, the Royal Aircraft Factory’s proposal for a B.E.2 replacement employed the same wings and horizontal tail surfaces as the B.E.2e, mated with a completely new fuselage and powered by the 140-hp RAF4a V12 engine. It was armed with a forward-firing machine gun, synchronised to fire through the propeller disc and with a swivel-mounted gun for the observer. It might easily have been given a designation in the B.E. series but was named the Reconnaissance Experimental No. 8 or R.E.8. Over 4,000 were built, eventually replacing the B.E.2 for all front line duties in Europe.

A number of alternative engines were also fitted at various times to the B.E.2 series. Some Royal Navy Air Service machines were fitted with the Curtiss OX5, a water-cooled V8 of similar size and power to the RAF1a, the air scoop replaced by a neat curved cowling and a car-type frontal radiator to address engine cooling. Performance was similar to that of the standard B.E.2c. A few Royal Navy Air Service B.E.2s were fitted with the 75-hp inline six-cylinder Rolls-Royce ‘Hawk’, again with a frontal radiator. A number of B.E.2 fuselages were employed without wings or tail surfaces as airship cars.

Several B.E.2cs were fitted experimentally with examples of the Hispano-Suiza engine. Of alloy construction with its cylinders cast on blocks instead of individually as in previous designs, it developed 150 hp from a mass not dissimilar to that of the RAF1a. Daimler-built 2599 was tested with a Hispano engine in March 1916 and, the following month, flown to the Central Flying School at Upavon for evaluation. Reports on its performance were favourable, but production of the Hispano engine and developments thereof could never keep pace with demand. Its use was largely restricted to aeroplanes such as the S.E.5 and Sopwith Dolphin, which had been designed around it, and no alternative engine was available without major modification to their design. None were ever made available for such obsolescent designs as the B.E.2.

However, 2599 retained its Hispano engine for a while and was fitted with a number of alternative radiator installations to find the most effective method of cooling, before moving on to experiments with superchargers.

At least one example, 4122, was fitted with an experimental variable pitch propeller developed by the Royal Aircraft Factory. Although successful, it was not considered necessary at the time, especially in view of its weight and additional complications.

Armament

Designed at a time when there was little difference between a military and sporting aeroplane, and when the duties of a military aeroplane were unclear, the B.E.1 and B.E.2 were intended to be efficient flying machines. No thought was given to them being armed, nor was it considered that their role would ever require it.

At the outbreak of war, aeroplanes of both sides flew reconnaissance and observation missions unarmed, and if by chance another aeroplane was seen, crews would wave to each other in a friendly fashion. But such gentlemanly conduct could not last for long and observers began to take pistols and rifles with them to take aim at an enemy aeroplane that came within range. The observer in the B.E.2 had been placed, as was common practice, in the forward cockpit at the centre of gravity so that the machine’s trim was unaffected were it to be flown solo. This position, surrounded by struts and wires with the propeller in front and wings to each side above and below, restricted his field of fire. It was therefore normal for the pilot to position his aeroplane so that the enemy machine was to his forward quarter where his observer had the best chance of a well-aimed shot. Even so, it was by no means uncommon for the observer to hit a part of his own machine.

The B.E.2’s first aggressive role was as a bomber in which capacity it was usual to carry either four 20 lbs bombs in racks under the lower wings or a 112 lbs bomb in a cradle beneath the fuselage. The bomb release was achieved by pulling a cable. If the machine was flown solo, a greater weight of bombs could be carried, especially if the range was short and the petrol tanks did not need to be completely filled. An accurate and dependable bombsight had yet to be devised, and the accuracy of the bombing depended as much upon luck as the skill of the pilot.

Armaments intended for use against balloons and airships included Le Prieur rockets which were fired electrically from tubes fitted to the outer interplane struts. Aiming was mostly down to luck but a number of observation balloons were destroyed. Efforts to mount a machine gun began after the introduction of the B.E.2c whose more powerful engine allowed additional weight to be carried. The gun chosen was the American-designed Lewis that weighed about 27 lbs not including the ammunition drum that held fifty rounds. The first mounting comprised a bracket on the fuselage side carrying a socket into which a pin, clamped to the gun at its centre of gravity, was placed so that the gun could be swivelled as needed to take aim. This was known colloquially as the candlestick mounting and appears to have been created, ad hoc, by squadron mechanics. This device allowed the user to fire both forwards and backwards, and gave a reasonable field of fire albeit at the risk of hitting his own machine.

The first official design for a gun mount, the No. 1 Mk.1, was a modified version of the same concept, but placed the mount on a front centre section strut and afforded both elevation and traverse. A modified version that could be folded flat against the fuselage side when not in use was designated No. 1 Mk.2. In either case, only one gun was normally carried and the observer was expected to move it from one side to the other as demanded. The candlestick mount was also occasionally fitted further back, allowing the pilot to use the gun when the machine was flown solo, the gun muzzle often being secured by wires to give a fixed line of fire. Similarly, the No. 1 mount, if fixed to the rear centre section strut, could be used by the pilot to fire forwards within the limited field of fire available to him.

Despite their rather crude appearance, the gun mounts could be used to good effect. On 19 September 1915, 2nd Lt Harold Medlicott of 2 Squadron with 2nd Lt Gilbert as his observer, were carrying out an artillery observation near Lens when they spotted an enemy two-seater. They positioned themselves to attack opening fire with a Lewis gun on the left-hand mounting from 100 yards. After a full drum had been fired, the Albatros caught fire, but Gilbert fired a second drum to make sure. Medlicott seems to have attacked every enemy aircraft he saw and after several inconclusive combats with Lt Rice as his observer, scored again on 11October with the front seat occupied by Lt Russel. Their victim was another Albatros two-seater that was shot down near Sailly-sue-Lys where the crew was taken prisoner. Medlicott also invented a mount in which the socket to carry the gun was attached to a bar between the front centre section struts and arranged so as to slide along as required. Thus a single gun could be fired to either forward quarter without the need to change mounts. This, although often referred to by the name of its creator, was officially designated gun mount No. 2 Mk.1. A wire guard was often used to restrict the travel of the gun’s muzzle and so prevent the user shooting his own propeller. The No. 2 Mk.2 and Mk.3 were minor refinements of the original design and did not change its basic concept or improve its effectiveness.

Captain L. A. Strange of 12 Squadron invented what was probably the most sophisticated mount of all. This comprised a swivelling pillar fixed between the cockpits with a toothed quadrant allowing the gun to be held in place at various angles of elevation. It could be employed by the observer to fire to the rear or by the pilot to fire forwards with equal facility. This was officially adopted as the No. 4 Mk.1 mount but was almost always referred to by its inventor’s name.

The No. 10 Mk.1 or ‘Goalpost’ was a frame fitted between the cockpits onto which the Lewis gun could be mounted to allow the observer, by turning in his seat or even kneeling on it, to fire directly to the rear. Since the muzzle of the gun was located over the pilot’s head, it must have been rather disconcerting to use, but did provide an effective defence against an attack from above and behind.

Despite the wide choice of gun mounts available, a number of machines remained unarmed in front line service. With the exception of the No. 4 and later versions of No. 2, these machine gun mountings were noted as obsolete in a training manual issued in July 1916, but continued in service throughout the war.

The ideal solution to arming an aeroplane, especially one flown solo, was to fix the machine gun to the front. However, the problem in a tractor design was to prevent bullets from hitting the propeller and pusher aeroplanes were deemed too slow to catch their prey. In the spring of 1915, a bizarre effort was made to combine the aerodynamic efficiency of a tractor design with the forward field of fire afforded by a pusher. Drawings were completed in June and a modification of B.E.2c, 1700, commenced. The observer’s cockpit was eliminated and the engine moved back, positioning the propeller fifteen inches ahead of the upper wing. The centre section struts were splayed outwards to clear the engine cylinder, a new broader centre section increasing the span to over forty feet. A plywood nacelle to house the observer was mounted on an extension of the propeller shaft, supported by struts added to the undercarriage and braced by wires to prevent it rotating.

The ingenious B.E.9, despite many favourable reports, failed to provide a viable solution to the problem of providing a forward-firing gun.

Modifications were completed by 13 August and the modified B.E.2c, now designated B.E.9, was flown to Netheravon for service evaluation on 25 August. The forward view was considered ‘excellent’ and the field of fire ‘better than any other seen here’. It was, however, criticised for its lack of dual control and on 31 August returned to the Royal Aircraft Factory for this to be provided. On 11 September, it was flown to France so that front line pilots and observers could operate it and offer their opinions. It spent time with several different squadrons, was flown over the lines and on 13 October, engaged in a brief and inconclusive encounter with a enemy machine while being flown by Lt Glen of 8 Squadron.

Reviews were at best mixed. The forward view and field of fire were generally praised but the lack of communication between the crew was seen as a problem. So, too, was the observer’s prospect for survival in the event of a landing on its nose as the B.E.2c was prone to do so on soft ground. The adoption was not recommended and the aeroplane returned to Farnborough on 9 January 1916. Although it now appears remarkable that no attempt was made to reverse the crew positions to place the observer in the back seat where he would have a clear field of fire against an attack from the rear, there was no superior substitute for what was already in use. Such a move would not have significantly improved the observers field of fire to the rear – at least until the invention of the synchronisation gear to allow a gun to fire forwards through the propeller disc – and rendered the machine virtually defenceless against a foe dead ahead.