Tank Encyclopedia Cruiser Mk.IV, A13

Arriving in the 5th Tanks, recruits were told it operated on the principle of ‘shit and efficiency’ – it didn’t matter what things looked like; what was vital was that they worked properly.

The sense that they were better than erstwhile horse soldiers – smarter, more technically proficient and well led – was all very fine but did not sit easily with the late events in France. Some other battalions of the RTR had distinguished themselves just before Dunkirk with an effective counter-attack against the advancing Germans at Arras. But as far as the 5th Tanks was concerned, it had been a dismal campaign in which the battalion had been scattered with just a single claimed kill of an enemy tank. At Thursley the Commanding Officer, Lieutenant-Colonel Dinham Drew, therefore drove his men hard to put the regiment back on its feet and restore its confidence. Infractions of discipline were swiftly punished, earning him the nickname ‘Detention’ Drew. He drove his young officers too, drilling them in the manoeuvres needed to bring a squadron into battle.

In addition to moulding his men, the colonel also had to oversee the re-equipment of the regiment, and the tanks that arrived in Thursley had plenty of peculiarities. Just as the army struggled to create new regiments, so industry strived to step up production massively, while embracing the technological changes needed to meet the Germans.

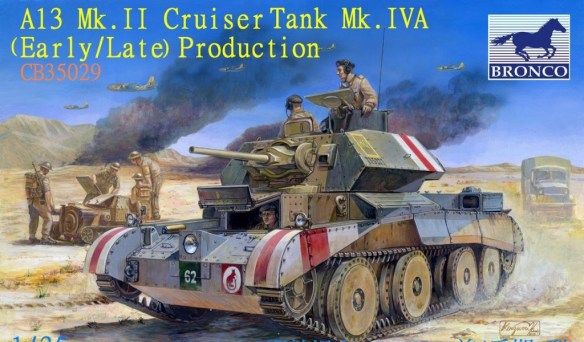

The 5th RTR had been built to a strength of fifty-two tanks. Four of these were being kept by the commanding officer and others in battalion headquarters, and sixteen went to each of the three squadrons. A Squadron, which had a reconnaissance role in the field, had been given tanks called A9s. B and C Squadrons were equipped with A13s. There were similarities between these two types, which both represented the evolution of what the army termed ‘cruiser’ tanks: they shared a main gun, the two pounder, and were lightly armoured. However, the steel plate on the front of the A9 was just 14mm thick, which was only enough to stop a rifle shot or shell splinters. The A13 had started with similar armour but been upgraded to 30mm. The A13 weighed in at thirteen tons and the A9 at twelve. They were designed for quick, decisive strokes rather than slugging it out.

Getting to grips with the tanks for the first time, those who had come through the wartime training system would have been struck by the cramped interiors of the A9 and A13. The War Office had decreed that the tanks should fit on standard railway flatcars, and this made them narrower than some continental designs. When squeezed from the top down, because a lower profile meant a smaller target, this compressed the available space within the armoured shell. For this reason the V12 Nuffield engine in the back of the hull was very hard to work on, and the turret, for example of the A13, particularly small. Three men had to fit inside it: commander, gunner and wireless operator or gun loader. The gunner had no hatch of his own in the turret roof and could only observe the world through the narrow aperture of his gun-aiming telescope as he was bounced about. The wireless operator and commander had their own hatches, but these were a tight squeeze for some of the battalion’s boxers or other big men who had to push one shoulder down through the hatch before the other. As those who had just been in France could testify, the design of these tanks added to the difficulty of maintaining them, and created a sense of claustrophobia, particularly if you worried about being able to get out quickly.

During the tactical debates of the inter-war years the army had ruled that there should be two types of tanks, cruisers like those given to the 5th RTR and ‘infantry’ tanks. The latter, as the name implied, were designed to support foot soldiers in battle. Consequently they were heavily armoured and slow-moving. The cruisers, by contrast, were to form armoured divisions that would be used for the more exciting stuff – racing forward to block a gap in friendly lines, or to exploit one in the enemy defences. The British theorists also expected the cruisers to do most of the tank-to-tank fighting, but the enemy could not be expected to adhere to these tactical distinctions decreed by the British General Staff. So when the Arras battle took place, in May 1940, it pitted British infantry tanks against German armour with results that were cheering but a little inconvenient for those who believed in having two different types of vehicle. The Matilda – the infantry tank – was much better armoured than the cruisers, with frontal protection almost three times as thick as that of the A13, and the Germans encountered considerable difficulties knocking out Matildas. The tank had proven a success even if the campaign as a whole had not.

All three tanks – Matilda, A9 and A13 – shared the same gun, the two-pounder or 37mm tank gun. This weapon had been designed to drive a small metal projectile, weighing two pounds and roughly the size of a small pear, through the armour of an enemy tank. The whole round, comprising the projectile and a brass case containing an explosive charge that sent it down the barrel, was about eighteen inches long; it could easily be picked up with one hand. Knocking out an enemy tank with a slug this small required a gun that could shoot it at high speed, and in this respect the two-pounder, which sent its shell down range at 2700 feet per second, was good for its time (the mid-1930s). The combination of a two-pound shot and this speed of travel was sufficient to pierce 50mm of armour angled at 30 degrees at a thousand yards. If it penetrated the enemy vehicle the shot might pass through a man, disable a vital piece of equipment or, since it was often red hot, cause the explosion of ammunition or fuel inside. Gunnery instructors appreciated that this might not happen on the first shot; it might take many hits to knock out the enemy tank.

The crews preparing their tanks for deployment from Thursley Camp had been taught that the two-pounder was their weapon of choice for dealing with enemy armour. If they came up against infantry, anti-tank guns or other resistance they were instructed to use the machine guns mounted on their tanks. There was no high-explosive shell for the two-pounder gun, a consequence of Tank Corps dogma that deemed a gun firing armour-piercing rounds only was sufficient to do battle with enemy ones, and of the practical difficulty of packing much power into so small a shell. The crews in any case were confident that their two pounders could sort out the Italian tanks in Libya – and in this particular matter their optimism was not misplaced.

As for the build of these tanks, it had something in common with Bristols, Morgans and Rileys, the great British sports cars of the day: there was a good deal of engineering ingenuity in them. The A9 had a power traversing system to help the gunner lay his weapon more quickly onto the target – one of the first tanks so equipped. The A13 had a new kind of suspension that allowed it to travel more quickly and comfortably across country. British tanks also embodied, like their sports-car counterparts, craftsmanship. They were built by British engineers – often in the same plants that built railway locomotives or ships – and each vehicle arrived in Thursley from the factory with a highly polished brass plate giving its serial number and manufacturers’ details.

The War Office contracted big industrial concerns as part of the mobilisation of British industry. A9 tanks were made by Harland & Wolff and Vickers-Armstrong; the A13 by Nuffield Aero, as well as the London, Midland & Scottish railway works. Tank production was also underway at several other factories that had previously made rolling stock or civilian vehicles. Many of the engineers were unused to working on tanks, and so production brought myriad challenges of fitting together components from suppliers they had not previously dealt with. ‘Concessions’, the permitted variations in the shape of parts, were generous, a fault that ‘cost millions of lost man hours’, according to Major George MacLeod Ross, one ofBritain’s leading tank designers. Contrasting British methods with what he saw a couple of years later in America, MacLeod Ross wrote:

We still pursued our love affair with ‘craftsmanship’, which may be defined as, ‘the ability to fit two things together which do not fit’. There was no place for craftsmanship in an American production plant, even the presence of a vice or a bench in such factories was regarded as a sign of incompetence. Accuracy was invariably the enemy of craftsmanship.

The fitters in 5th Tanks knew all too well what he was talking about. A complex machine like a tank was only as strong as its weakest component. Within weeks of getting their vehicles, soldiers were reporting frequent breaks in the tracks on the A9 as well as all sorts of problems with the fan belts and engine cooling on the A13. These issues of reliability might have been overcome by deploying large numbers, but shifting production beyond the scale of a cottage industry proved problematic. During the first year of the war, by pressing so many new plants into service, Britain managed to produce about 1300 tanks – a respectable total, and one comparable to Germany’s. But the British made a dozen different types, half of which were already obsolete, whereas the Germans concentrated production on a smaller number of more effective models. Crucially, they also insisted upon building to exacting engineering tolerances, reaping their reward in superior reliability.

While training in Surrey the 5th had put on a number of demonstrations, one of them for some American visitors. The US army had gone even further than the British in its disarmament years, disbanding entirely its nascent tank corps. Even though the United States was officially neutral at this time, the country wa~ rapidly re-establishing both armoured regiments and mass-production facilities, while the British government was negotiating to buy weapons from American factories. The US army saw the RTR as natural partners in the business of tank soldiering.

By October 1940 the feeling in southern England was that the country had weathered the worst that the Luftwaffe could do. Hitler had postponed the invasion of Britain, while the war was spreading worldwide. Italian forces were operating in East Africa, as well as launching bombing raids on Egypt, Palestine and Malta. Japan, meanwhile, aligned itself with Germany and Italy. The 5th Tanks had reformed itself and rediscovered a well-practised confidence in its tactical exercises.

On 5 October the regiment was assembled in Thursley Camp for a short, sharp address. Colonel Drew told them the battalion had been ordered on overseas service. The men would be entitled to ’embarkation leave’ of a few days each.

The Desert

Lieutenant Arthur Crickmay, although callow in years and lacking seniority, understood the desert better than many of his brother officers. He had travelled to the Middle East three years earlier, while still a student, exploring the way through Egypt and northern Libya with a friend. Then, during early exercises he had polished his desert navigation skills to the point at which other officers had come to rely upon them. These abilities saw him posted to the reconnaissance section of 6th RTR, where by late 1940 he bore witness to a remarkable reversal of fortunes. The Italians, despite their great superiority in men and equipment, had been beaten and thrown back. Starting on 8 December, the British had launched what was meant to be a short-term counter stroke, moving westwards inland, bypassing the Italians at Sidi Barrani on the Egyptian coast and threatening their line of communication with Libya. Lieutenant Crickmay spoke for many when he observed that ‘we never dreamt how far we should eventually go. The Italian army seemed a huge and menacing thing in those days.

Having deployed into the field in April 1940, Crickmay had already learned many of the lessons of soldiering in this wilderness that his comrades in 5th Tanks were about to undertake. Of course, the old hands tried to impart some of these pearls of hard-earned wisdom, but often their words were ignored or drowned out in the general flow of bumf and bombast from headquarters.

The young lieutenant knew all about the savage variance of climate that boiled you one month and froze you the next. He also knew about the problems of supply, which could push a man to his physical limits within days. In France, the 5th had been able to forage for food and drink in villages but here, with the exception of the odd Bedouin trading in eggs or poultry, there were almost no possibilities to find food or water if the system failed.

On 27 December, the tanks of 5th RTR were unloaded in Alexandria. The British War Cabinet had decided to reinforce the army in Egypt, so the quaysides were a scene of constant activity for weeks. The opinions of the British soldiery who stepped blinking into the Egyptian sunlight were frequently harsh. Many remarked on the squalor of the scene, the pushiness of the locals and the strangeness of the food. One 5th Tanks man recorded that their port of disembarkation was ‘dirty, filthy, smelly’. Another, a corporal in A Squadron who had served with the Tank Corps on the North West Frontier, later said of his first impressions of Egypt: ‘I didn’t like it at all – I never liked it – it was scruffy.’ In time, they would come to dream of a few days in Cairo or Alex, just as Lieutenant Crickmay did.

By the end of 1940 there were hundreds of thousands of British servicemen and women in Egypt. There was an extensive network of airfields, bases and transport facilities that ran from Cairo, down the Nile valley to Alexandria and the sea, an area known collectively as ‘the Delta’.

For the 5th Tanks, the pleasures or indeed the social humiliations of the Cairo social scene would have to wait. The voyage out had been so comfortable that the battalion’s officers felt the men needed to be thrown into some hard work, and soon. Both of the ships that carried them to the Middle East were commercial liners that had been taken up a short time before. Only the dancing girls and cabaret artistes had been off loaded before they became troop ships: the soldiers were waited upon by stewards, ate fine food and drank copious amounts of alcohol. ‘Each day we bought six bottles of beer … sat on deck and drank them and ate our ice cream,’ Trooper Wardrop reported in his diary. ‘The weather was lovely and the tan was improving daily.’ Wardrop saved a bottle of rum and, once ashore, ‘on Hogmanay I was on guard and we killed it as the clock was striking’.

The early days of 1941 were a period of intense activity, as tanks were modified in the workshops and painted in desert colours, and exercises began on the training grounds near camp. Those running 5 RTR soon found themselves having to organise a swap with the 3rd, which had also come over as part of their brigade. The 5th handed its A9 tanks over to the 3rd, and got A13s in return, so that each battalion had one main type of vehicle. It made logistical sense, and the 5th weren’t complaining because they felt the later, heavier model was the better tank, but it was just a small taste of the endless chopping and changing by those in command that would characterise the months to come. Each new brainwave meant hours or days of hard work for the men. For A Squadron, who had manned the A9s before they went to the 3rd, this meant forgetting much of the preparation they had undergone at Thursley Camp and learning the peculiarities of a new wagon.

The soldiers got down to the job with alacrity, with good news from the front about further advances into Libya creating ‘a festive atmosphere’. But as the British pushed further into Libya, this caused worry as well as celebration for Lieutenant-Colonel Drew, the Commanding Officer. He knew that many of the A13s in his regiment had motored several hundred miles; the machines they had received from 3rd Tanks were particularly worn out. Given the standard of ‘craftsmanship’ of these machines, it was reckoned unwise to go more than a thousand miles between major engine overhauls. The way they had been put together, these tanks simply shook themselves apart if not regularly serviced. Yet it was about five hundred miles from 5th RTR’s camp to where the army was fighting. The first couple of hundred could be done by train, but the battalion faced the prospect of driving hundreds further before it could even come into action.

The 5th Tanks had left Cairo late in January, their armour being taken to the Egyptian port of Mersa Matruh by train, the echelon’s lorries and most of the men by road. From then on there was no choice but to push the tanks forward under their own power, up and over the Halfaya Pass and across the border into Libya, past Bardia and Tobruk. The first tank train had left Cairo on 27 January and they reached EI Adem, an aerodrome south of Tobruk, ten days later.

There, machines were moved about within the unit. The A13s brought out from Britain ended up in C Squadron whereas the others, particularly A Squadron, got clapped-out machines from other regiments. People were shifted too, and to his delight Trooper Solomon was moved from the Left Out of Battle contingent to driving a tank belonging to the officer commanding A Squadron. Others lounged about, getting a run into Tobruk for a beer and a swim, or reading in between working on their tanks.

The army in late March found its front at EI Agheila, hundreds of miles to the west, one of those places where a rare change in the coastal geography presented a defensible position – in this case, a bottleneck between the Mediterranean and some inland salt flats impassable to tanks. The 5th prepared to move up to this front, dispatching recce parties along the desert route that reached the coast near Ajdabiya, just south of Beda Fomm and east of El Agheila. One of these, under Lieutenant Deryck MacDonald, got so badly lost that the RAF were sent to scan the desert, without luck. The hapless young officer and his recce party eventually turned up a few days later.

During the stop at El Adem the regiment had tried to bring its A13s up to scratch with much maintenance. Mindful that many of them were passing the mileage where engines were normally overhauled the Battalion Technical Officer had been sent off to Cairo to obtain more motors. Some staff type there seemed to promise them, but the order to move forward again came before anything could be done. On 21 March the road move, nearly three hundred miles along the Trigh al Abd, began. For Solomon and other new men it was an education in the physical hardships of tank soldiering. They spent long hours being bounced and kicked by the hard surfaces of the moving machine they served. They were caked in buckets of sand thrown up by the tracks of the vehicle in front, and if they came sharply to a halt, were often engulfed in a sand cloud of their own making.

Each day began with the sun shining behind the tanks as they travelled westwards. Most had absolutely no idea where they were. There was no roadway, so they simply followed the tracks through the sand. It didn’t take long for the breakdowns to start, the first vehicle spluttering to a halt with an ignition problem. The fitters who stopped to repair it found the engine took hours to cool down, and ‘by the time we did move off the desert was horribly empty’. Each squadron had one truck with four or five trained mechanics on board. In addition, the Battalion Technical Officer had several specialists helping him. But the small staff of experts proved inadequate on this, their first proper desert march. There were simply too many vehicles breaking down. ‘We passed many tanks, but fortunately we had nothing to do with them, because they were write-offs,’ said one of the 5th’s fitters.

The move to Ajdabiya proved a gruelling learning experience in many ways. Crews that did manage to get underway again after repairs soon discovered that if they had not been paying careful attention to their map reading, noting the distances between waypoints and the few landmarks that appeared, they got hopelessly lost. Many men cheerfully quaffed their water ration, assuming that the half-gallon allowed per man per day would be replenished by some unseen echelon every morning. By the third day some were so thirsty that they were leaving seat cushions from their vehicles out at night, having discovered that dew formed on them and the rubber could be wrung out into a tin. It tasted disgusting, but if the alternative was a thumping headache, dry mouth and nothing to drink, what choice was there?

Having limped into the forward area, with leading elements arriving on 6 February, the battalion tried to pick up the pieces. Many tanks had been left along the desert road, and it did not appear the brigade, division or army had any plan or troops detached to recover them. Others, who had got lost en route, appeared in odd places over the following days. A Squadron was sent forward with other reconnaissance troops to man outposts at the front of the army while the rest of the 5th tried to prepare for battle.

In truth, though, their country had hardly given them the tools for the job. Many of the A13s were by this time approaching two thousand miles on their engines, twice the recommended period between overhauls (one had reached 2002 miles). The tracks had an estimated life of two thousand miles, after which the metal pins that held them together became so stretched that they would frequenly break.

Sitting down in his tent on the last day of March 1941 Major Southon, the Battalion Technical Officer, was a man full of woes. He made notes of the state of the equipment under his care, scanning the returns given in by each of the squadron fitter sergeants. Of the fifty-three tanks on the regiment’s books, just twenty-seven were at the correct end of the desert road and in working order. The rest were scattered between there and Tobruk, hundreds of miles to the east, where the nearest properly equipped workshops were located. Next to twenty of the tanks listed on his ‘Tank State 30/3/41’, the Technical Officer wrote ‘engine u/s’. It meant ‘unserviceable’.