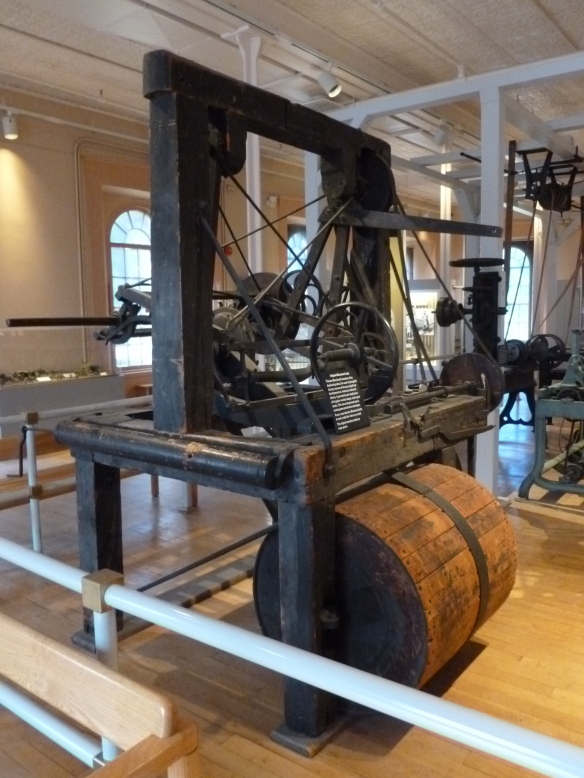

BLANCHARD’S “LATHE”

This lathe, or shaper, invented by Thomas Blanchard, was a key development in the history of gunmaking. Installed at the Springfield Armory in the early 1820s, the lathe allowed the duplication of the irregular shapes of wooden stocks. Although the shaper shown is no longer in use, this technology is still used in some parts of the world.

Roswell Lee

The Springfield Armory was the most important manufacturer of military firearms in the US between 1794 and 1968. Established in 1777 as the country’s key weapons store during the Revolutionary War, the Armory became famous for pioneering the kind of mass-production techniques that allowed precision-engineered products to be built in large numbers. Led by Roswell Lee between 1815 and 1833, the Armory’s mechanized production techniques had a huge impact, not only on the firearms business but also on American industry as a whole.

George Washington himself recommended Springfield, Massachusetts, as the location for an arsenal. He appreciated the high, defensible site near the Connecticut River, and the proximity of the river and roads was convenient for transportation. In 1777, the arsenal was founded to store a range of ammunition and arms. When the move was made to weapons manufacture in the 1790s, there was an expansion to lower-lying land to the south and west, near water that could provide a source of power. Here a foundry and workshops were built, beginning a tradition of firearms manufacturing in the area.

AN INDUSTRIAL PIONEER

In 1794, the Springfield Armory began to manufacture firearms, starting with muskets. As a major arms producer it made weapons for the US forces in the War of 1812, for Union troops during the American Civil War (1861-65), and in the Spanish-American War (1898). The Armory became a center for innovation as engineers and craft workers found ways of making better weapons and improving the efficiency of the production process. Some of these developments were groundbreaking, placing the Armory at the forefront of the Industrial Revolution. For example, in 1819, inventor Thomas Blanchard devised a machine on which workers could produce rifle stocks. Blanchard’s machine, usually known as a lathe, was strictly a shaper, working in a way similar to a modern key-cutting machine in which an original shape is copied on to a stock blank. It enabled gun stocks to be mass-produced for the first time. Springfield also pioneered the production of guns using interchangeable parts (a field also developed by Samuel Colt and many others), allowing firearms to be assembled at speed and repaired with ease. This method of production relied not only on new machinery but also depended on the division of labor, with separate workshops for different parts of the production process, precise measuring and gauging of components, and good quality control. By the time of the Civil War, the Armory was using state-of-the- art machines for milling, turning, grinding, and shaping, some driven by water, others by newly installed steam engines. These technological advances were accompanied by up-to-date management and accounting methods, introduced by Colonel Roswell Lee, who became superintendent of the Armory in 1815.

VOLUME PRODUCTION

The Armory’s production facility was adaptable, producing a range of muzzle- loading weapons. In the 1840s, the Armory achieved the goal of producing firearms with interchangeable parts, and was able to build guns in large numbers during many conflicts of the 19th century. From about 85,000 Charleville Pattern smoothbore muskets (without interchangeable parts) produced between 1795 and 1815, the Armory’s volume of production jumped to 800,000 Springfield Model 1861 rifled muskets (with interchangeable parts) during the Civil War. The techniques of mass production developed at Springfield during the 19th century made the Armory well placed to produce firearms in the huge numbers needed for major 20th-century conflicts. New improvements, such as the arrival of electrical power, also helped the Armory in this respect. The early 20th century saw the production of bolt-action repeating rifles, including the Krag rifle, designed in Norway, and the Model 1903, which was designed in Springfield. The retooling and adaptation required to produce these new weapons was a challenge, but thanks to machine upgrades and a reorganization of the workforce, they were successfully put into production and demonstrated that the Armory could build quality firearms en masse. The Armory’s Model 1903 was used in both world wars. It was followed by a new generation of semiautomatic firearms, including the famed Garand rifle of 1936, which made US infantrymen much better equipped than those in other parts of the world who were issued with slower bolt-action rifles. Such products kept the Armory going through the mid-20th century, until the US government decided to rely solely on private manufacturers and shut down the facility in 1968.