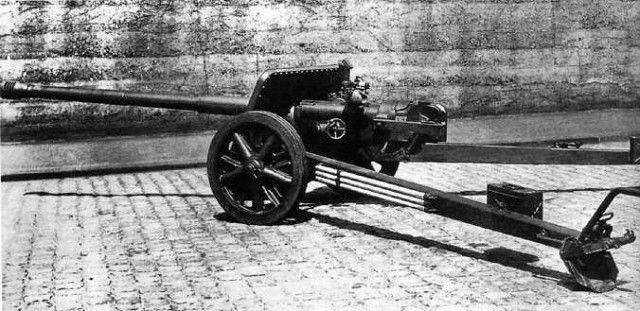

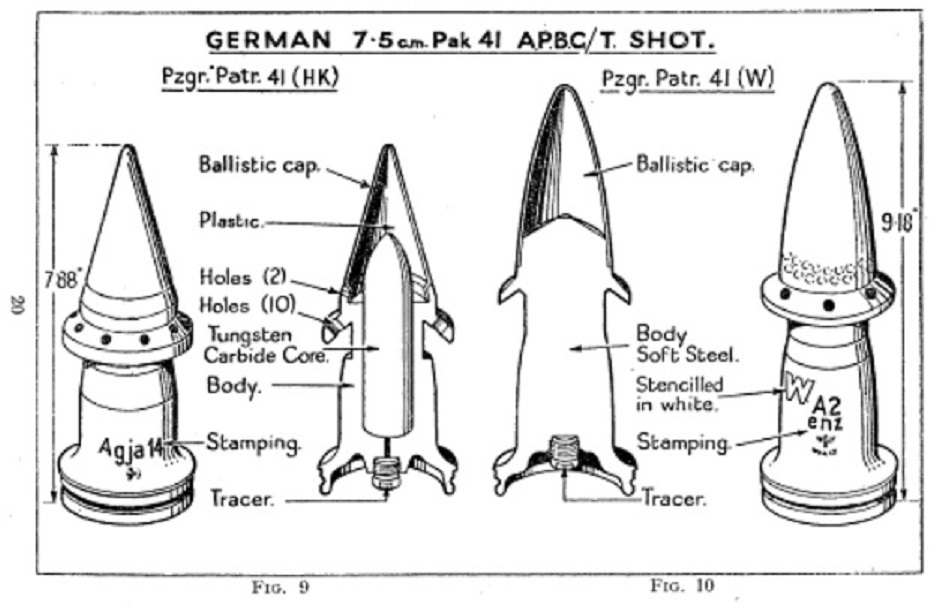

The 75/55-mm tapered bore 7.5-cm Pak 41.

Artillery is not a field in which you might have expected,

in 1939, to find anything secret; it appeared to be a fairly pedestrian field

of activity, with developments limited simply to making minor improvements in

metallurgy or fire control or detail design. Surely there was nothing that one

nation could come up with which would have escaped the attention of every other

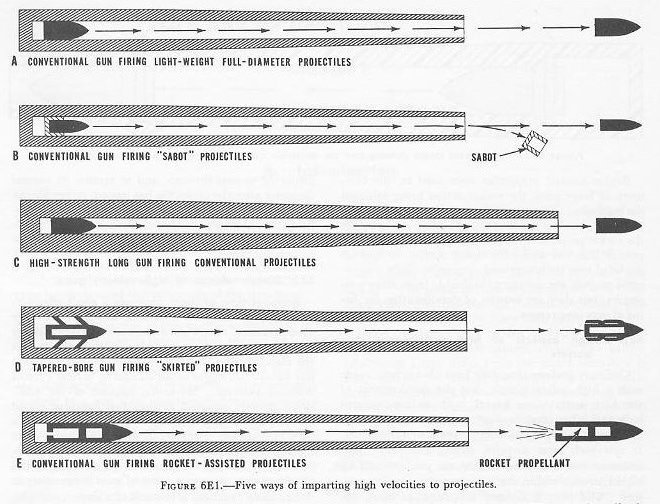

artillery-producing nation? Or was there? The taper-bore guns In 1903 a German

called Karl Puff patented a design for a gun in which the bore, instead of

being the same diameter from end to end, was tapered; it started out at the

breech end at, let us say, 10mm diameter and then gradually got smaller until

at the muzzle it would be 7mm diameter. He completed the idea by designing a

bullet with an expanded sleeve around its waist; this was of 10mm diameter, so

that it loaded correctly into the bore, but when fired it passed down the bore

and the gradual taper squeezed the sleeve down until it left the muzzle with

the sleeve firmly reduced into a prepared groove in the bullet so that the

bullet had the usual smooth exterior shape.

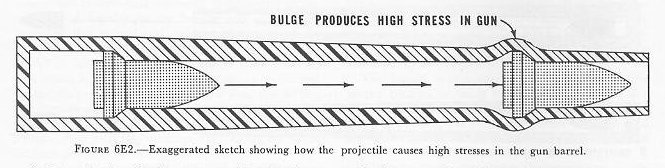

His object in designing this device can be explained by some

simple arithmetic. Suppose the base area of a bullet when loaded to be 10

square centimetres. And suppose the gas pressure generated by the propellant

charge to be 10,000kg. The pressure on the bullet will therefore be 1,000kg per

square centimetre, which will produce some specific velocity. But as the bullet

goes down the bore, the base diameter shrinks and thus the base area shrinks

with it. The design of the charge can be adjusted to provide a constant gas

pressure, so that by the time the bullet reaches the muzzle the pressure

remains the same at 10,000kg but the base area has, let us say, halved. So the

pressure on the bullet is now 2,000kg per square centimetre, and this will have

increased the velocity by a considerable amount. Tapering the bore therefore

develops a far higher muzzle velocity than could be achieved by a

conventionally rifled parallel bore.

Puff’s intention was to obtain high velocity so as to get a

flatter trajectory and a shorter time of flight, and thus improve the accuracy

of the weapon. And everybody thought it was rather a clever wheeze, but how do

you drill a tapering hole and then rifle it? And how do you make these

complicated little contracting bullets? Ah, said Herr Puff, that’s your

problem. But if you do succeed, than I’ll take my percentage in licence fees.

Puff’s patent duly expired without ever being worked, and

some time in the 1920s another German, a gunmaker this time, decided that

technology had moved along a little since 1903 and perhaps Puff’s idea might be

workable. The gunmaker was Hermann Gerlich, and in conjunction with a partner

called Halbe he eventually produced a taper-bore sporting rifle which he

marketed as the Halger. With the aid of the RWS ammunition company he also

developed a practical bullet, and, as Puff had predicted, the Halger rifle had

high velocity and a flat trajectory which, even though it was expensive, made

it popular with hunters, so Halbe and Gerlich were able to make a living. But

Gerlich, like many a gun inventor before him, had his eyes firmly fixed on a

military contract, and in 1928-33 he walked the corridors of war departments in

Germany, Britain and the USA in an attempt to interest them in a powerful

sniping rifle. They were all interested, but the cost of such a weapon was

daunting, and there were no takers. The Americans experimented at Springfield

Arsenal and developed a number of bullets, one of which produced a muzzle

velocity of 7,100 feet per second (compared with around 2,800fps for a standard

military rifle), but the programme was abandoned early in 1939.

Gerlich went back to Germany in 1933 and got in touch with

the RheinmetallBorsig company. Hitler had become Chancellor, the Versailles

Treaty was repudiated, re-armament was beginning, and ideas were wanted. They

were particularly wanted in the field of anti-tank gun design, because the

problem there was to produce a weapon light and handy enough to be easily moved

about and emplaced by a couple of infantrymen but powerful enough to penetrate

the armour of tanks. Fortunately, at that period, the armour on tanks was not

of any great thickness, since it was only intended to keep out ordinary small

arms bullets and shell splinters.

Reduced to its basics, the penetration of armour is simply a

question of momentum; throw something hard enough and the mass and velocity

will carry it through. Even a plain lead ball will go through armour steel if

you can get it moving fast enough. So the Halger rifle, with its high velocity,

was a promising idea. In order to survive the impact with the target, the

bullet was given a core of tungsten carbide; this was enclosed in a soft steel

casing which had two flanges or’skirts’which could be squeezed down in the bore

so as to present a smooth outline at the muzzle.

Rheinmetall, after various experiments, decided on a barrel

tapering from 28mm to 20mm; for security reasons it was known as the schwere

Panzerbüchse 41 (`heavy anti-tank rifle’) but in every respect it was a small

conventional artillery piece on a two-wheeled, split-trail carriage, with a

small gun-shield and a hydro-pneumatic recoil system. The whole equipment

weighed only 5051b (229kg) and it fired a 131-gram bullet at 4,595 feet per

second (1,400 metres/second) to go through 2.6 inches (66mm) of steel armour at

500 yards range.

It would be idle to suppose that security was so tight that

nobody outside Rheinmetall knew what was going on, and there was soon a whisper

around the armaments engineers in Europe that somebody was playing with a

taper-bore weapon. As a result one or two other people began looking at the

idea; one was a Czech who, in 1938, got out of Czechoslovakia just ahead of the

occupying Germans and fled to Britain. There he began trying to interest the military

in his taper-bore theories. He met with a stony response. In the July 1940 the

Ordnance Board, tired of his supplications, poured cold water on the idea.

`The principle has been investigated in the past. It is

quite clear that, as regards attack of armour, a weapon of this type cannot be

regarded as possessing any advantages over a normal weapon of equal weight and

of the same calibre. As regards the application of the principle to the

2-pounder gun, the Board recommend No Further Action.’

A few days later a liaison officer lately returned from

France submitted a report on the Halger taper-bore rifle, an example of which

he had acquired in France. He got much the same treatment:

`The system was investigated by the Small Arms Committee

some years ago (See SAC Mins 1935 or so, under ‘Halger Rifle’), Herr Gerlich

himself being employed by the War Department. He was not the inventor of the

coned bore and skirted projectile, the credit for this being due to Karl Puff

whose patent was taken out in about 1903. [Actually Brit Pat 18601 of

27/8/1904]. The system was developed by Gerlich in collaboration with Halger.

It is still being pursued by Kern, in Switzerland, and by Pacetti at Otterup in

Denmark. The Kern proposal is being dealt with in current Proceedings. Neither

ammunition nor weapons are yet within measurable distance of becoming fit for

use in war. No Further Action to be taken.’

About eight months later the British Army captured a

Panzerbüchse 41 in the Libyan Desert and flew it back to Britain to be examined.

It was found to have a muzzle velocity of 1,388m/sec (4,555ft/sec) and to

penetrate 70mm of homogenous armour at 100 yards range.

By that time Rheinmetall had moved on and had designed the

4.2cm Panzerjagerkanone 41 (`tank-hunting cannon’) which was more or less an

enlarged version of the first weapon. This started out at 42mm calibre and

ejected the projectile at 29.4mm calibre. The shot weighed 11.8 ounces (336g),

had a velocity of 4,150ft/sec (1,265m/sec) and could go through 3.43 inches

(87mm) of armour at 500 yards range, or 2.36 inches (60mm) at 1,000 yards. This

weapon came into service early in 1941.

Krupp, that other famous German gunmaker, had also looked at

the taper-bore idea. In 1939, looking well ahead to the inevitable increase in

the size and strength of tanks, the army had asked Krupp and Rheinmetall for a

7.5cm anti-tank gun. Rheinmetall produced a conventional gun. Krupp was

attracted to the taper bore but was faced with a major engineering problem in

producing a tapering gun barrel of that calibre and size and therefore invented

a variation which became known as the `Squeeze-bore’.

The 7.5cm Pak 41 gun was a conventionally rifled gun with a

barrel 116 inches (2.95m) long. To the end of this barrel was attached a

smooth-bore extension 37 inches (950mm) long which had a varying internal

taper. As the flanged shot left the muzzle of the rifled section and passed

into the extension, it first went through a section tapered at 1-in-20 for

about 10.6 inches (270mm), then into a more sharply tapered section at 1-in-12

for another 6.7 inches (170mm) and then into a parallelsided section for the

rest of its travel, emerging squeezed down to 5.5cm calibre. The advantage of

this method of manufacture was that only a short length of the barrel had to be

tapered and this did not have to be rifled. The wear on this taper as the shot

passed through at high speed was such that the extension piece was worn out

after about 500 shots, but it was simply held on the barrel by a screwed collar

and could be replaced in a very short time in the field and with the minimum of

tools.

The gun fired a tungsten-cored shot weighing 5.71b (2.6kg)

at a muzzle velocity of 3,690ft/sec (1,125m/sec) and could defeat 7 inches

(177mm) of armour at 1,000 metres range, striking at a 30 degree angle, or 4.9

inches (124mm) at 2,000 metres. This was a really formidable performance for

1941 and but for one thing this might have been the standard German army

antitank gun for the remainder of the war. The one thing which defeated it, and

also defeated the other two taper-bore guns, was the demand for tungsten to

provide the cores for the projectiles. Tungsten was not native to Germany and

had to be imported; the supply was restricted, and there was a constant demand

for it for the manufacture of machine tools and other vital production

equipment. A tungsten machine tool could be sharpened or rebuilt when worn; a

tungsten projectile fired at an enemy was so much tungsten lost for ever. And

since production was the more vital of the two conflicting demands, tungsten

for ammunition was cut off in the late summer of 1942. And once their special

ammunition was gone, the taper-bore guns went to the scrap pile. So

effectively, indeed, that few specimens of the 7.5cm Pak 41 survived the war.

But if the shortage of tungsten ruled out the taper-bore as

an anti-tank weapon, it certainly did not rule it out in other applications,

and now the anti-aircraft specialists began to look at the system. In the

anti-aircraft business the principal problem was the interval between firing

the gun and having the shell arrive in the vicinity of the target; a great deal

could happen during that time, and any way of shortening the shell’s time of

flight by increasing its velocity was carefully scrutinised. Therefore the

taper bore, with its substantial increase in velocity, was a highly attractive

idea; the difficulty lay in the design of the projectile. In an anti-tank gun

the `payload’ was a lump of inert metal, but in an anti-aircraft gun the

payload had to be high explosive. And the dangers which lay in squeezing a high

explosive shell were self-evident. With armour-piercing shot the core acted, as

it were, as an anvil, while the tapering barrel acted as a hammer, but with an

explosive filling the squeezing action had to be carefully controlled so as not

to place excessive pressure on the shell body. Two solutions appeared to work

satisfactorily. In the first type, the shell was of smaller diameter than the

bore and was fitted with two supporting bands of sintered iron, one at the

shoulder and one at the base. These were attached in the manner of driving

bands, and performed the same function in spinning the shell, but they were

malleable so that as the bore reduced they were swaged down and folded back, so

that at the muzzle the shell left with two smoothed-down bands which set up

minimal air drag. The second method was rather more complex. Three soft studs

were fitted at the shoulder of the shell and the base was deeply indented with

a semi-circular groove around the body. Into this grove went a malleable skirt

with a circular base which fitted into the groove and acted as a sort of

flexible ball-joint, turning backwards as the skirt was squeezed down by the

reducing bore. At the same time the soft studs at the shoulder were pressed

down and deformed until they were mere bumps on the outside of the shell.

Again, the result was that as the shell left the muzzle the studs and skirt had

been reduced to streamlined excrescenses which set up minimal drag. It was

claimed that either of these designs could give a reduction in the time of

flight by about 30 per cent, though there appear to be no trials results to

back this up. Like so many other developments, the taper-bore anti-aircraft gun

was overtaken by events and the war ended before the design could be perfected.