. Cannons<br />

in Henry’s artillery train were typically referred to at the time originally as<br />

“pieces of ordinance” or “ordinance guns,” to denote their<br />

casting according to regulations or official ordinance. In the course of<br />

repeated usage the term eventually evolved into the modern term<br />

“ordnance” to describe artillery. </p>

<p>Upon assuming the throne in 1509 at the age of eighteen,<br />

Henry inherited an artillery organization suffering from years of neglect by<br />

his father, Henry VII. Although at the time the Tower of London and other royal<br />

arsenals held respectable numbers of cannons in their inventories, many were<br />

unserviceable. The English artillery train, moreover, was also in complete<br />

disarray, and the office of Master Gunner, or chief of artillery, had lain<br />

vacant for some time. To make matters worse, Henry also discovered that only<br />

one English foundry possessed the capability to cast cannon barrels. </p>

<p>The ambitious young monarch lost little time in initiating<br />

an arms program to remedy the appalling situation. Henry first appointed<br />

Humphrey Walker, apparently the only competent gun founder left in England, to<br />

the office of Master Gunner. The capable Walker then assumed command of twelve<br />

subordinate master gunners to oversee cannon production and to train<br />

professional gun crews. Henry’s other efforts included, in 1537, the founding of<br />

the Guild of St. George as a professional organization for his ordnance<br />

experts. Eager to pursue his Continental ambitions, Henry also supplemented his<br />

domestic production by acquiring forty-eight cannons abroad in The Netherlands<br />

from the Master Founder of Malines, Hans Poppenruyter. These included a group<br />

of approximately 45-pounder guns christened the “Twelve Apostles” and<br />

another sixteen guns of a class weighing between 3,000 and 4,000 pounds each.<br />

The latter guns required fourteen draft horses each: specially bred mares that<br />

Henry also obtained from The Netherlands. </p>

<p>Henry ‘s investment justified itself in 1513, when his<br />

artillery train played a major role in the relief of the English garrison of<br />

Calais at the 16 August Battle of Guinegate. Later that month Henry’s<br />

artillery, reinforced by that of his ally, Maximilian I, proved equally<br />

effective in the taking of the town of Therouanne and, in September, Tournai . </p>

<p>During the early sixteenth century English cannon makers<br />

were capable of making large weapons, or “great cannons,” weighing<br />

from 150 pounds up to 737 pounds. Henry vigorously promoted cannon production<br />

at Buxted, south of London in Sussex. Owing to his patronage, Buxted attracted<br />

an international mix of skilled gunmakers, including Italians, a Frenchman<br />

named Baude, a German named van Cullen, as well as the Englishmen Robert and<br />

John Owen and Ralphe Hogge. Although such professional master founders<br />

commanded considerable respect as well as high salaries and even pensions, other<br />

foundry workers were not so well compensated. Women and children were also<br />

employed by the foundries and were typically paid in food and wine or cider. </p>

<p>The inventories of Henry’s artillery holdings at the Tower<br />

of London and other locations indicate that his arsenal ultimately included<br />

numerous types of guns, including bombards weighing approximately 3 tons each<br />

and requiring twenty-four horses for transport, large culverins and sakers, and<br />

smaller falconets. A number of examples of Tudor cannons still survive, such as<br />

an 840-pound falconet cast by John Owen in 1551 and a saker cast by Henry’s<br />

Italian-born founders at Salisbury Place in 1519. The falconet is 7-feet,<br />

3-inches in length with a 2.8-inch bore and was held in storage in the local<br />

parish in Jersey. The saker is a 6-foot, 11-inch weapon. Gun founders did not<br />

gain the necessary skill to produce cast iron cannon on a practical basis until<br />

well into the sixteenth century. Records indicate that two Frenchmen, Rafe Hoge<br />

and Peter Bawd, poured the first English cast iron guns at Buxted in 1543.<br />

Other reports list Peter Bawde (sometimes spelled Bawd) and Peter van Collen as<br />

making cast iron mortars with 11- to 19-inch bores, as well as explosive cast<br />

iron balls. Although these early cast iron guns were still much heavier than<br />

bronze guns of comparable size, they were significantly safer, more reliable,<br />

and more accurate than wrought iron pieces. The new iron-working method also<br />

lent itself to other applications, and the town of Buxted continued as one of<br />

England’s largest cast iron-manufacturing centers for three centuries, its<br />

other products including such diverse items as fireplace inserts and grave<br />

markers. </p>

<p>A new technique, applicable to both bronze and iron guns,<br />

further advanced the founding of gun barrels. During the sixteenth century<br />

founders began pouring barrels as a solid casting, rather than using a mold<br />

with a central mandrel to create the bore. Although this technique required<br />

drilling out the bore with a hardened steel reamer, it created a more precise<br />

fit for ammunition. It also helped to prevent flaws in the casting that led to<br />

cracks or air pockets within the metal- defects that led to early metal fatigue<br />

and burst barrels. The development of small air pockets in the molten metal,<br />

creating a honeycomb effect in the finished barrels, remained a problem for gun<br />

founders and was more apt to occur in cast iron barrels. Although bronze was<br />

less susceptible to the problem, its cost was some ten times that of iron. For<br />

this reason cannon makers continued to make bronze guns well into the<br />

nineteenth century. Cast iron guns also continued to be made despite their<br />

inherent danger, for simple economic reasons.</p>

<figure class=)

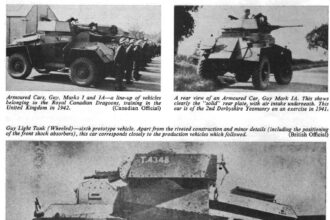

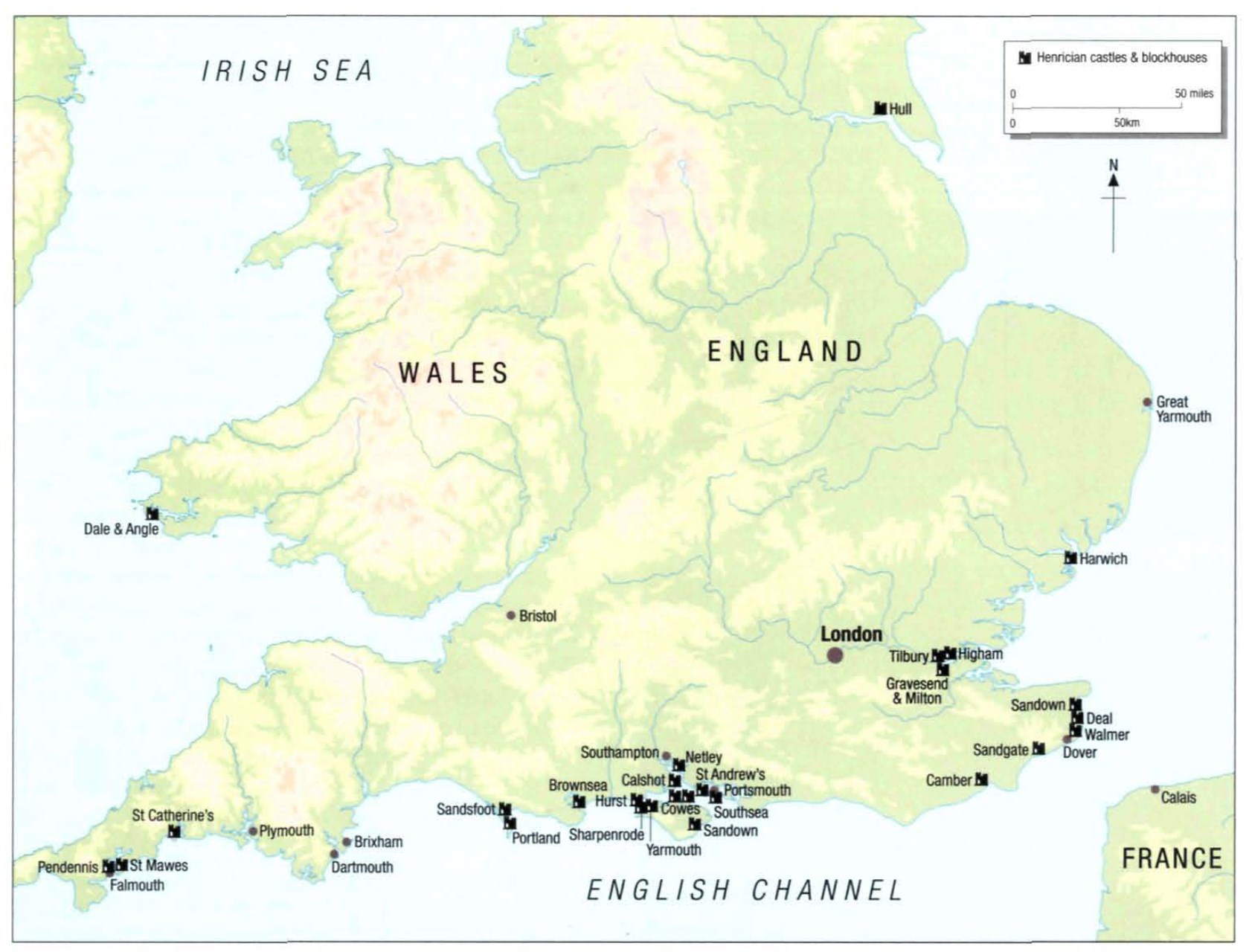

The location of the various castles and blockhouses constructed during

the fortification phases between 1539 and 1547.

Henry’s Artillery

Forts

The proliferation of gunpowder artillery inevitably forced

military engineers throughout Europe to rethink castle construction. In siege

after siege the fifteenth century had proved that the towering, flat-faced

masonry walls of early fortifications were hopelessly vulnerable to heavy guns.

These medieval structures, moreover, had been constructed without consideration

for the installation of heavy defensive guns.

Architects thus began re-engineering existing fortifications

by lowering and thickening their walls. Another measure-the addition of thick

earthen facings to the walls’ outer surfaces-also provided a cushioning layer

to lessen the impact of projectile strikes. The mounting of heavy defensive

cannons required the construction of reinforced embrasures both to accommodate

the guns themselves and to withstand the stresses of their weight and recoil.

On the Continent, sophisticated new “Italian Trace” forts built

specifically for artillery appeared and incorporated low, thick walls and

bastions to provide multiple angles of fire over carefully prepared approaches.

In addition, multileveled artillery towers, such as at Castelnaud in France,

also made their appearance at strategic locations throughout Europe. Such

towers employed the most advanced engineering principles of their day and were

all but impregnable to any but the most determined besieger.

The improvements in defensive works, in turn, ultimately

forced tacticians to devise new siege craft methods. The most effective method

to emerge incorporated the construction of angled approach trenches. These

ditches provided protection from the besieged castles ‘ guns and allowed the

gradual advancement of siege guns to within their most effective range.

Henry’s break with the Roman Catholic Church and subsequent

excommunication by Pope Paul II in 1538 set England on a collision course with

the powerful Catholic kingdoms of Europe. Almost overnight Henry found himself

facing a papal-backed coalition of France and Germany, and he began

preparations to fortify England’s coast in anticipation of invasion.

He subsequently ordered the construction of a string of

forts along England’s coast from Cornwall to Dover. Unlike the Italian Trace

forts common to the Continent, Henry’s “blockhouse” or

“bulwark” castles incorporated dry moats, interlocking defenses, low

profiles, and rounded, sloped ramparts to deflect artillery projectiles.

Possibly based on original designs by the famous German Renaissance figure

Albrecht Durer, Henry’s forts also featured numerous cannons in well-designed

embrasures with specially designed vents to carry away choking,

target-obscuring gun smoke. Although never tested in battle, such castles as

Deal and Walmar remain as testaments to Henry’s zeal in protecting his kingdom.