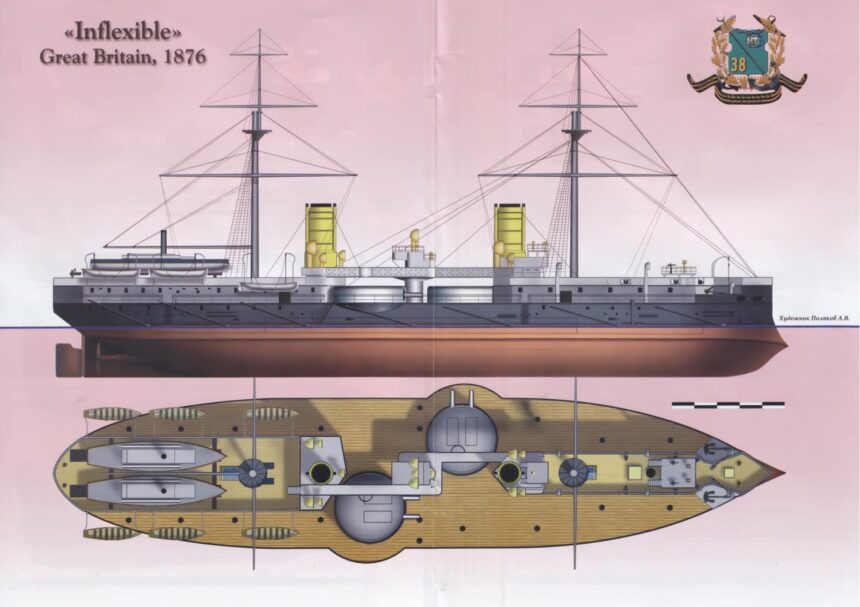

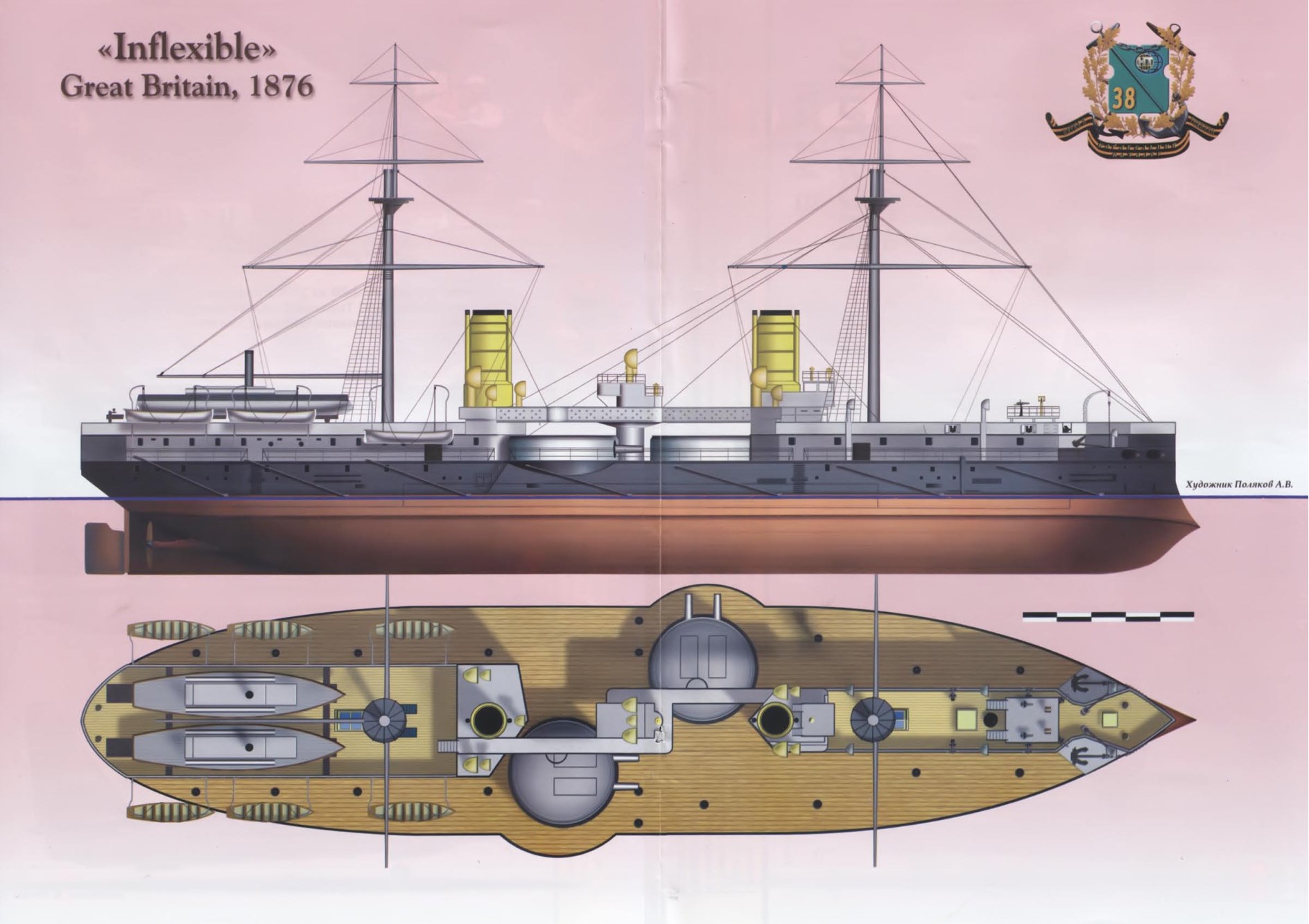

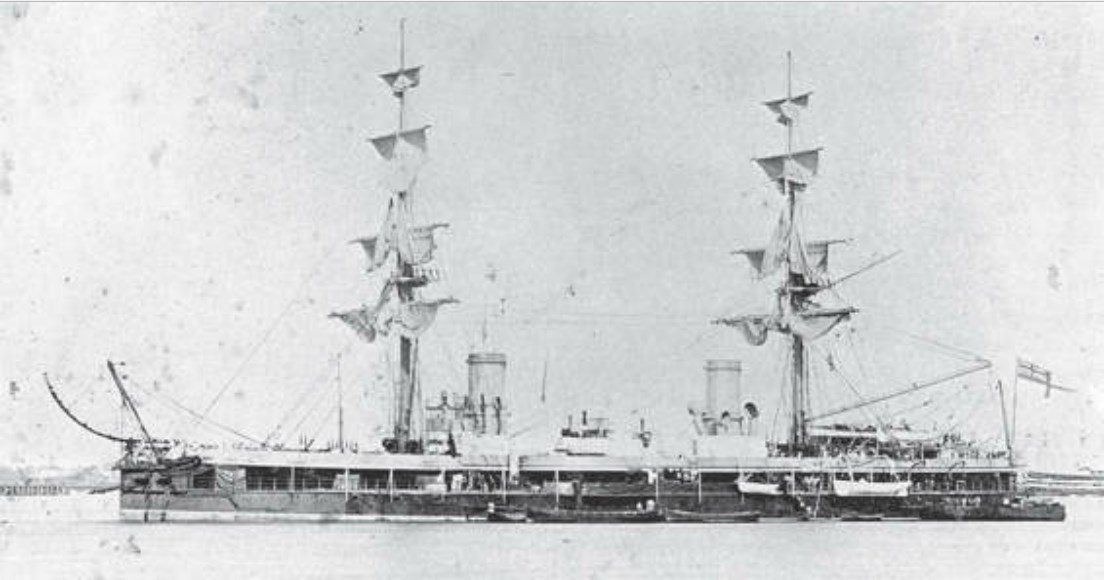

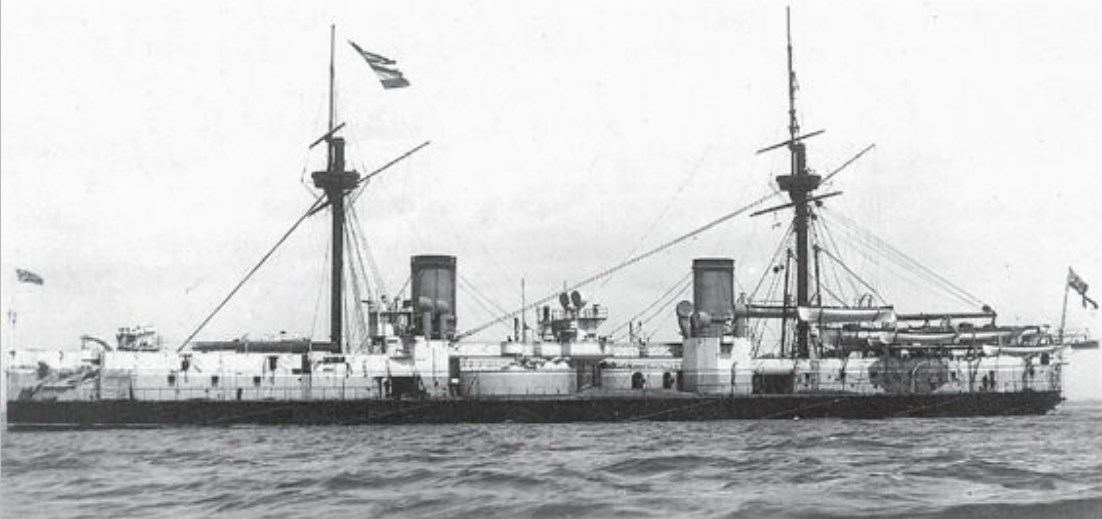

Inflexible, 1876, as completed with sails for training. Note the torpedo launching chute over the stem.

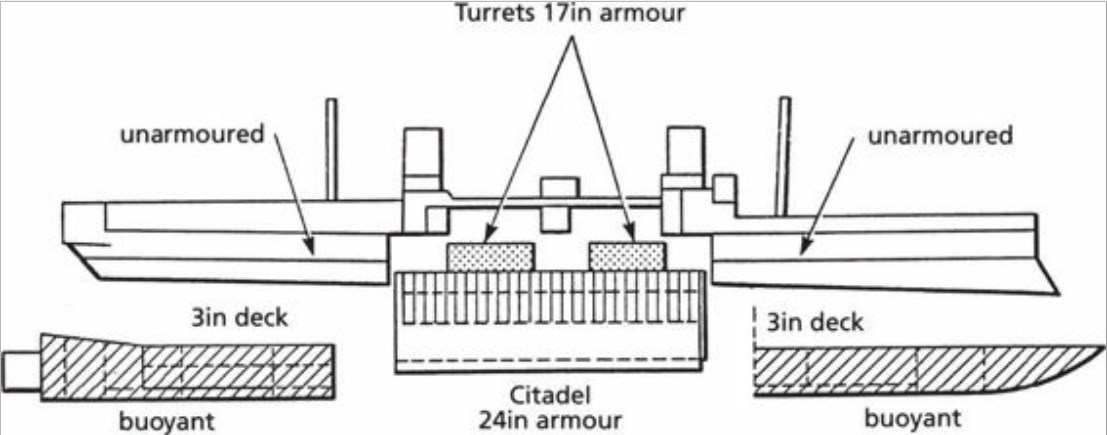

The design concept of Inflexible was of a raft, the citadel, which

would float if the ends were destroyed or flooded. The ends were closely

subdivided and protected by a thick deck. A light, unprotected structure above

provided accommodation.

In 1885 Inflexible’s sailing rig was replaced by two military masts.

In a letter to The

Times of 1 January 1877, Edward Reed described the Inflexible as `… a huge

engine of war, animated and put into activity in every part by steam and steam

alone. The main propelling engines are worked by steam, a separate steam engine

starts and stops them; steam ventilates the monster, steam weighs the anchors,

steam steers her, steam pumps her out if she leaks, steam loads the gun, steam

trains it, steam elevates or depresses it. The Ship is a steam being .’

The 1873 Estimates envisaged the building of a single,

improved ‘Fury’ (in fact, this meant Fury, not yet renamed, with the

modifications which made her Dreadnought). The problem facing Barnaby was

stark; the 12.5in, 38-ton gun fitted in recent ships could fire an 820lb

projectile through 15.7in of iron armour at 1000yds. Fury’s 14in belt

(amidships) was already inadequate and, furthermore, both Woolwich and Elswick

claimed that 50-ton guns were within existing capabilities with even larger

guns in the near future.

The early studies retained the main features of Dreadnought

with the two twin 38-ton turrets augmented by a number of smaller guns en

barbette amidships. In one such study a single 50-ton gun in a turret was

squeezed in amidships. The 14in belt was retained amidships but the thinner

belt at the ends was omitted and a thick transverse bulkhead fitted at each end

of the belt. Thus the much admired end-to-end belt of Devastation was already

abandoned for what must have been a very small saving in weight.

By this time Woolwich was speaking with confidence of a 60-ton gun and Barnaby was driven to a more radical solution. The main requirements seem to have been set by Barnaby himself, though presumably after discussion with Board members and others. The armament was to consist of two twin turrets with 60-ton guns capable, if possible of being changed to 80-ton guns when available. White described the problem: ‘At first it was contemplated to have 60-ton guns and the ship was laid down on this basis. Finally, in 1874 it was decided to adopt 80-ton guns, which involved an increased weight aloft of 200 tons, and considerably modified the design, the draft and displacement having to be increased. There had been some previous instances of ships getting ahead of the settlement of their gun designs but never so serious one as this. Unfortunately, it was only the first of a long series of similar difficulties … .’ The armour was to be concentrated over a short citadel with a maximum thickness of 24in. She was to be fast – 14kts – and capable of using the Suez Canal at light draught (24ft 4in). Barnaby’s ideas were generally welcomed and the design was progressed incorporating some detail improvements mainly suggested by the DNO, Captain Hood, but with some later ideas from Barnaby. The following paragraphs describe the design as it finally evolved.

The design concept was of a very heavily armoured raft

containing the machinery and magazines on which the two turrets were carried.

The ends were protected by a strong armoured deck below the waterline, by close

subdivision and by buoyant material whilst a light superstructure provided

living space. Even if both ends were flooded, the armoured box was intended to

have sufficient buoyancy and stability to float upright. This stability

requirement led to a wide beam which, in turn, meant that the turrets could

fire close to the axis past the narrow superstructure, limited by blast damage

to the superstructure. She was fitted with anti-rolling water tanks to reduce

the severity of rolling but these were ineffective.

The earliest studies of this configuration showed 60-ton guns though provision was made to mount 100-ton guns when they became available. Woolwich built an experimental 80-ton MLR which completed in September 1875 with a 14.5in bore. After tests, it was bored out to 15in and after further tests in March 1876 it was finally enlarged to 16in bore with an 18in chamber, accepting a 370lb charge. This gun fired a total of 140 rounds-215,855lbs of iron from 42,203lbs of powder – mostly against what was known as ‘Target 41’ which had four 8in plates separated by 5in teak. The standard system of grooving used with studded shell proved troublesome and in final form it had thirty-nine shallow grooves (‘polygroove’) with a lead gas check at the base of the shell.

The production guns-80-ton, Mark I-were mounted in twin

turrets each weighing 750 tons and 33ft 10in external diameter. These turrets

had an outer layer of compound armour with 18in teak backing and an inner layer

of 7in wrought iron. The projectile weighed 16841b and when fired with the full

charge of 450lbs brown prism powder had a muzzle velocity of 1590ft/sec and in

tests could penetrate 23in of wrought iron in either a single thickness or two

plates spaced. The interval between rounds was said to be between 2½ and 4

minutes. To load, the guns were run out and depressed against ports in the deck

through which hydraulic rams loaded the guns. Two of these monstrous guns

survive on the train ferry pier at Dover, though the turret design is rather

different and an early studded shell is in the Naval Armament Museum, Gosport.

Inflexible’s citadel was protected at the waterline by a strake of 12in plate, 4ft deep, backed by 11 in teak containing vertical frames. Behind this was another 12in plate backed by 6in horizontal frames, filled with teak followed by the shell of two thicknesses of ⅝in plate. The total thickness of this waterline belt was 4lin, weighing 1100lbs/sq ft and this thickness was preserved in the protection above and below, the thickness of teak increasing as that of the iron was reduced. Above the waterline strake there was a 12in outer plate and an 8in inner plate whilst below the thicknesses were 12in and 4in.

It is not clear why the armour was in two thicknesses as a 22in plate was made by 1877 and it was already recognised that two plates are inferior to a single plate of the same total thickness. A test in 1877 showed that a single plate 17-17½in thick was equivalent to three plates of 6½in. The waterline belt of 24in in total was the thickest belt ever carried on a battleship but it was only 4ft high and would have been of limited value. It does not seem that this protection was tried in final form. It was claimed that this protection was invulnerable to guns similar to those she carried and even to the 17.7in, 100-ton Elswick guns mounted in Italian ships but it was clearly the end of the road for wrought iron as the weight was already at the very limit of what could be carried.

The protection for the ends was a very sophisticated combination of measures. The first line of defence was a 3in wrought iron deck, normally 6-8ft below the waterline. The space between this deck and the middle deck, just above water, was closely subdivided and used for coal and stores which would limit the amount of water which could enter from holes in the side. In addition, narrow tanks 4ft wide and filled with cork were arranged at the sides between these decks and extending 4ft above the middle deck. Inside these cork-filled spaces there was a 2ft coffer dam filled with canvas packed with oakum. All these fillings were treated with calcium chloride to reduce their flammability although tests showed this was not very effective. This scheme has much in common with that which Reed proposed to the 1871 Committee.

In 1877, Reed wrote to Barnaby and later to The Times

claiming that calculations which he and Elgar had made showed that the

stability provided by the citadel was inadequate if both ends were flooded.

Despite a comprehensive rebuttal by Barnaby, an enquiry was set up chaired by

Admiral Hope and consisting of three distinguished engineers, Wooley, Rendel

and W Froude. Their investigation was extremely thorough, entering into aspects

of naval architecture never previously studied.

Their report concluded that it was most unlikely that both

ends would be completely flooded but that if this did happen, the Inflexible

would a retain a small but just adequate margin of stability in terms of the GZ

curve. Their comments on the difficulty of actually hitting the enemy ship are

of interest – remember the Glatton turret and Hotspurs initial miss! They

listed the problems as the relative movements of the two ships, the smoke

generated (470lbs of powder per round), the rolling and pitching of the firing

ship, the lack of any way of determining range and the deflection due to wind.

In particular, they noted that it was customary to fire the guns from a rolling

ship when the deck appeared horizontal at which position the angular velocity

was greatest. (Note also that Froude had showed that human balance organs are

very bad at determining true vertical in a rolling ship.) All in all, hits

anywhere on the ship would be few and those in a position to flood the ends few

indeed.

A shell exploding within the cork would destroy it locally

but tests showed that a shell hitting light structure would explode about of a second later during which it would

travel 6-10ft, clear of the cork. The canvas and oakum filling of the coffer

dam was quite effective at reducing the size of the hole made by a projectile

passing through. Both the cork and the coffer dam were tested full scale with

the gunboat Nettle firing a 64pdr shell into replicas. The Committee also

pointed out that shells were unlikely to enter the space between the waterline

and armoured deck except at long range when hits were even less likely.

Though the Committee thought it was unlikely that the ends

would be riddled (filled with water) and even less likely that they would be

gutted (all stores, coal, cork etc, blown out with water filling the entire

space), they examined these conditions with extreme care. Stability curves were

prepared and Froude carried out rolling trials on a 1-ton model both in his

experiment tank at Torquay and in waves at sea. The movement of floodwater

within the ship acted to oppose rolling in waves, as in an anti-rolling tank.

The effect of speed on the trim of the flooded model was also examined. Their

conclusion was that the ship should survive this extreme condition but would be

incapable of anything other than returning for repair.

This investigation was far more thorough than any previous study of the effects of damage and owed much to White’s calculations and Froude’s experiments. It was the first time that GZ curves of stability had been drawn for a damaged ship and the importance of armoured freeboard was brought out and it must be a matter for regret that similar work was not carried out for later ships. With the invaluable gift of hindsight, one may suggest two aspects not fully brought out. The first was the vulnerability of the citadel armour itself, particularly bearing in mind the shallow 24in layer, in two thicknesses, and the increasing power of guns. The second point was the assumption that the watertight integrity of the citadel would endure even when multiple hits had riddled the ends. The Victoria collision was to show that doors, ventilation and valves do not remain tight after damage and Inflexible would probably have foundered from slow flooding into this citadel. Barnaby claimed that she was designed to withstand a torpedo hit with the centreline bulkhead giving only a small heel – but he did not envisage flooding extending beyond one transverse compartment.

However, it is difficult to see a better solution to the

design requirement and the concept received some vindication from the battle of

the Yalu Sea on 17 September 1894 when two Chinese ironclads, Ting Yuen and

Chen Yuan, to Inflexible’s configuration, but smaller, received a very large

number of hits and survived. To some extent, the 1913 trial firings against the

Edinburgh may be seen as justifying the concept. Opponents of the Inflexible

mainly favoured protected cruisers whose only protection was similar to that at

the ends of the Inflexible which they derided. White gives her cost as £812,000

though other, much lower, figures have been quoted. There were two diminutives

which call for no mention.

‘The Ship is a Steam Being’

Reed’s letter, quoted at the beginning of the chapter,

referred to the increasing use of auxiliary machinery. Some early examples

include; a capstan in Hercules (1866), hydraulic steering gear, fitted to

Warrior in 1870, and a steam steering engine for Northumberland as well as the

turrets in Thunderer and later ships. The number increased rapidly and

Inflexible was truly a ‘steam being’. Her auxiliaries comprised:

1 steering engine

2 reversing engines

2 vertical direct fire engines

2 pairs steam/hydraulic engines to work the 750-ton

turrets

1 capstan engine

4 ash hoists

1 vertical direct turning engine

2 40hp pumping engines, total capacity 4800 tons/hr 2

donkey engines for bilge pumping

2 steam shot hoists

4 auxiliary feed, similar to donkey engines.

2 Brotherhood 3 cylinder for boat hoisting

4 Brotherhood 3-cylinder fan engines

4 Friedman ejectors

2 horizontal direct acting centrifugal circulating pump

The list above does not mention ventilation fans but it is

virtually certain that these were fitted. It was some time before satisfactory

ventilation systems were developed. An electric searchlight was tried in Comet

in 1874 and the first permanent fitting was in Minotaur in 1876. Inflexible had

800-volt d.c. generators by the US Brush company. These powered arc lights in

the machinery space and Swan ‘Glow’ lamps elsewhere. The Swan lamps were

connected in series and it was a year before the 800-volt system killed its

first victim. She was even launched by electricity; when Princess Louise

touched a button, a wire fused and the bottle of wine fell and weights crashed

onto the dog shores.