The third gun whose production occupied Krupp’s designers after 1937 was this 80cm monster. In common with most superweapons many legends have grown up around the 80cm K(E), and with the passing of the years it is becoming increasingly difficult to sort the wheat from the chaff; the following information appears to approximate to the truth and is substantiated by examination of documents and drawings, statements by Krupp employees and correspondence with eyewitnesses.

The weapon was conceived some time in 1935 partly as a serious project and partly as a propaganda stunt, when the Heereswaffenamt (army weapons office) enquired of Krupp what size of weapon would be needed to defeat the fortifications of the Maginot Line by direct assault. In response to this, ballistic data was calculated for hypothetical guns of 70, 80 and 100cm calibre and sent to the army. There the matter rested until a visit by Hitler in March 1936 to the Krupp works. There he apparently asked the same question and was given the same figures; he was also told that although manufacture of such a weapon would be difficult it would not be impossible. No definite commitment was made by Hitler, but Gustav Krupp von Böhlen und Halbach-knowing his man-gave instructions for design work to commence on the 80cm model and early in 1937 drawings were laid before the Heereswaffenamt. They were approved and manufacture began in the summer of the same year.

The production of such a monster was not easy (particularly the forging and machining of the barrel, jacket and cradle), and it was soon apparent that it would not be ready by the Spring of 1940 in accordance with the original estimate. The Maginot Line was overcome by other means, but when the French campaign was over Hitler reportedly carpeted the Krupp management and demanded results. Whether this had any effect is doubtful, but the gun barrel was successfully built by the end of 1940 and fired at proof early in 1941. Finally, early in 1942, the complete equipment was assembled at the Rugenwalde firing range and underwent its final tests in the presence of Hitler himself.

The finished weapon was code-named Gustav Gerät by the Krupp management in honour of Gustav Krupp, and was duly presented to Hitler as Krupp’s gift to the war effort. By that time, too, a second gun, codenamed `Dora’ (after the wife of the designer) was ready for delivery and components for a third were under construction.

After its test firing `Gustav’ was sent to join the siege of Sevastopol. It fired its first service round on 5 June 1942 from Bakhchisary, some 16km north of Sevastopol and fired 48 shots at various targets, all of which were very thoroughly demolished. The most spectacular shot was one which penetrated 30m of earth to detonate inside an underground magazine at Severnaya Bay.

At the end of the siege Gustav was withdrawn and shipped back to Essen to have the barrel re-lined; proof and practice, plus service, had added up to some 300 shots and the barrel was worn out. It was now the turn of `Dora’, and she was sent to Stalingrad, arriving there in late August 1942. There is no record of her activities there, and she was hurriedly withdrawn when the Soviet counterattacks began to threaten.

Thereafter the records are scanty; there is room for the belief that Gustav appeared briefly outside Leningrad but the siege ended before it could be brought into action. Both guns reappeared at the Rugenwalde proof ground in 1943 for a few practice shots, but after that nothing is known until May 1945 when parts of Gustav were found in Bavaria by the US 3rd Army. Parts of Dora were later found in the Leipzig area, and parts of the third gun, which was never completed, were found at the Essen factory and on the Meppen proof ground. It seems that there was not sufficient to build up a complete gun, and eventually everything was scrapped.

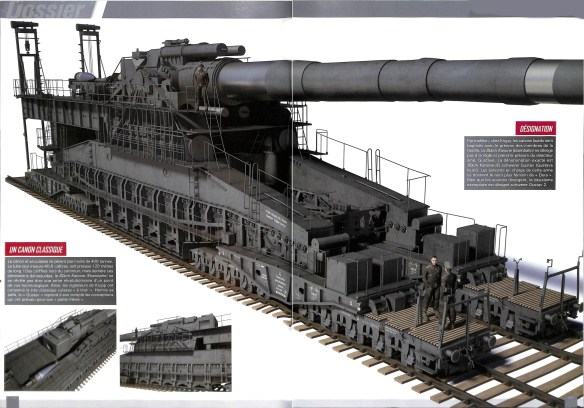

The construction of such a large equipment obviously had to be in sections in order to transport the components within the loading gauge: when assembled the gun was 42976mm(141.00ft) long, 7010mm(23.00ft) wide and the maximum height was about 11600mm(38.06ft). For movement the unit dismantled into the following sections: breech-ring and breechblock, barrel (in halves), jacket, cradle, trunnions and trunnion bearings, all of which were carried on special separate flatcars. The remainder of the mountings-comprising the upper carriage, the lower carriage and the bogie units-was split longitudinally so that, as well as being dismantled from the top down, each section was divided into halves. These pieces were carried in a number of trains using more special flatcars, together with the bogie units on their own wheels, ammunition wagons, coaches for the crews and a dismantled large gantry crane. On arrival at the chosen position a four-rail double track was laid for the gun, together with two outer tracks on which the travelling crane was erected. The right and left halves of the bogies were then shunted into place on the gun tracks and connected together. The remainder of the components then arrived piece by piece and the mounting was erected with the aid of the crane.

The barrel was then assembled by inserting the rear half into the barrel jacket and connecting the front half, which was thereafter locked in place by a massive joint nut. The assembled barrel fitted to the cradle, and the whole assembly was lifted on to the mounting. The breech was then lifted and fixed to the barrel by another joint nut. The whole process of preparing the site and erecting the gun took up to three weeks, and a force of 1420 men (commanded by an officer holding the rank of Generalmajor) was occupied in the task.

Further projects involving this weapon were considered after its successful debut at Sevastopol. It was intended to produce a 52cm gun known as Lange Gustav to fit the same mounting; this was to fire a 1420kg(3131lb) projectile to a range of 110km(68.35mile), a 52/38cm sabot shell to 150km (93.21mile), or a 52/38cm rocket-assisted sabot shell to 190km(118.06mile). It was considered that the gun would then make a good cross-Channel bombardment gun. Had this ever been done it would have given a large part of England a severe shock: sited on Cap Griz Nez the weapon would have commanded an arc running from Portsmouth through Henley-on-Thames, Luton and Cambridge to Lowestoft (though it is doubtful whether it would have fired more than once before the inevitable air retaliation arrived). Indeed it may be that the prospect of attempting to conceal such a weapon was enough to stop the plan. As an interim measure designs were drawn up for a Peenemünder Pfeilgeschoss (Peenemünde arrow shell) that could be fired from the 80cm barrel (presumably smooth-bored); two suggestions were an 80/32cm model ranging to 140km(86.99mile) or an 80/30.5cm model ranging to 160km(99.42 mile), but none of these projects ever passed the planning stage.

After all is said and done, it has to be admitted that the 80cm K(E) was a gross waste of time, money, material and men. Far better results would have been obtained had all the wasteful dissipation of raw material and time been put-for example-into another five or six 38cm Siegfried guns. But the Gustav Gerät nonetheless remains the largest gun ever seen by the world (not the largest calibre gun) and is likely to remain so.

Data

Calibre: 800mm/31.50in

Length of gun: 32480mm/1278.74in/106.56ft

Length of bore: 28957mm/1140.04in/95.00ft.

Rifling: 96 grooves, right-hand twist.

Breech mechanism: horizontal hydraulically operated sliding block, percussion fired.

Traverse: Nil, fired only from a curved track.

Elevation: + 10° to + 65°.

Weight in action: 1350000kg/2976750lb/1328.90 ton.

Length over buffers: 42976mm/1691.97in/141.00ft.

Performance

Firing high explosive shell weighing 4800kg (10584lb/4.73ton).

Full charge: velocity 820mps/2690fps, maximum range 47000m/51400yd/29.20mile.

Firing concrete-piercing shell weighing 7100kg (15656lb/6.99ton).

Full charge: velocity 710mps/2330fps, maximum range 38000m/41557yd/23.61mile.

Ammunition Separate-loading, cased charge.

Projectiles

80cm Sprgr: fuzed Hbgr Z 40K, weight 4800kg (10584lb/4.73ton).

This was a ballistic-capped shell of conventional design, with the nose fuze beneath the cap and an extended striker rod connecting the fuze mechanism with a plug at the tip of the cap. Three double driving bands of sintered-iron were fitted, with a single soft-iron sealing ring of larger diameter behind them. The explosive content was approximately 400.00kg(882.00lb).

80cm Gr Be: fuzed Bd Z C/38, weight 7100kg (15656lb/6.99ton).

This was of similar appearance to the high explosive shell but was base fuzed, the shell having a concealed hardened point beneath the ballistic cap. The explosive content was approximately 200.00kg(441.00lb).

Propelling Charges

Two charges were provided, one for the high explosive shell and one for the anti-concrete shell. The charge was split into three sections, the Hauptkart in a cartridge case, and Vorkarten 1 and 2 in cloth bags. The Hauptkart was common to both shells, but the Vorkarten were of different weights for the different shells and were prominently marked fur sprgr or fur gr be accordingly. It appears that the standard charge was the Hauptkart and both Vorkarten; some reports have spoken of a reduced charge for short range firing, presumably the Hauptkart and one Vorkart, but there is no confirmation of this.

Hauptkart: 1050kg/2326lb Gudol R P.

Vorkart 1 (Sprgr): 535kg/1180lb Gudol R P.

Vorkart 1 (Gr Be): 465kg/1025lb Gudol R P.

Vorkart 2 (Sprgr): 655kg/1444lb Gudol R P.

Vorkart 2 (Gr Be): 585kg/1290lb Gudol R P

Total weight of charge fired with HE shell: 2240kg/4939lb.

Total weight of charge fired with anti-concrete shell: 2100kg/4631lb.

Primer

The percussion primer C/12nA was used.

Case Identification Number.

None: no case mark was used, for presumably none was necessary. The case was 1300mm (51.18in) long with a base diameter of 960mm (37.80in) and was difficult to confuse with any other.